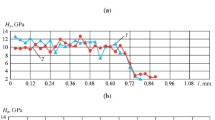

According to the electrochemical theory of corrosive wear, a thin protective film is formed on the surface of a metal in an aggressive environment, the destruction of which results in a severe corrosive wear. One of the factors contributing to the destruction of a protective film is deformation. To determine the type of the deformation and its influence on the protective film state, three cycles of investigations were carried out. The analysis of the results obtained is made using the experimental and theoretical method.

Similar content being viewed by others

References

S. N. Sidorenko and N. M. Yakupov, Corrosion is the Ally of Accidents and Catastrophes [in Russian], RUDN Publishers, Moscow (2002).

Kh. N. Nizamov, S. N. Sidorenko and N. M. Yakupov, Prediction and Prevention of the Corrosion Fracture of Structures [in Russian], RUDN Publishers, Moscow (2006).

N. M. Yakupov, The Laboratory of the Nonlinear Mechanics of Shells: History and Recent Developments [in Russian], Institute of Mechanics and Mechanical Engineering of the Kazan Research Center, Russian Academy of Sciences, Kazan (2006).

É. M. Gutman, Mechanical Chemistry of Metals and Corrosion Protection [in Russian], Metallurgiya, Moscow (1981).

A. M. Lokoshchenko, “Methods for modeling the environmental influence on creep and long-term strength of metals,” Usp. Mekh., No. 4, 90–120 (2002).

N. M. Yakupov, R. G. Nurullin, A. R. Nurgaliev, and S. N. Yakupov, Testing Technique for Metal Membrane Specimens under Stress Conditions and the Test Equipment Implementing this Technique [in Russian], Patent No. 2296976, MPK G01N 17/00. Publ. April 10, 2007. Bull. No. 10.

N. M. Yakupov and A. R. Nurgaliev, “Investigation of the mechanical characteristics of thin-walled structural elements subjected to corrosive wear and being under loading,” in: Pressing Problems of the Continuum Mechanics. On the 15-th Anniversary of the Institute of Mechanics and Mechanical Engineering of the Kazan Science Center of the Russian Academy of Sciences [in Russian], Publishing House of the Kazan State University, Kazan (2006), pp. 244–254.

N. M. Yakupov, Sh. Sh. Galyaviev, A. R. Nurgaliev, and S. N. Yakupov, “Condition of cooling tower structures and prevention of their failure,” Izv. Vuzov. Ser. Probl. Énerg., No. 7-8, 36–42 (2006).

N. M. Yakupov and A. R. Nurgaliev, “On the influence of defects on the mechanical characteristics of membranes operating in an aggressive medium,” Izv. Kazan. Gos. Archit.-Stroit. Univ., No. 1 (7), 56–59 (2007).

N. M. Yakupov and A. R. Nurgaliev, “The influence of mechanical defects on the properties of loaded thin-walled structural elements in an aggressive medium,” Stroit. Mekh. Inzh. Konstr. Sooruzh., No. 3, 14–18 (2008).

N. M. Yakupov, A. R. Nurgaliev, and S. N. Yakupov, “Procedure for testing films and membranes under conditions of a uniform distributed surface pressure,” Zavod. Lab., 74, No. 11, 54–56 (2008).

G. V. Berenshtein, A. M. D’yachenko, and A. I. Rusanova, “A mechanochemical dissolving effect,” Dokl. AN SSSR, 298, No. 6, 1402–1404 (1988).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 2, pp. 76 – 84, March – April, 2012.

Rights and permissions

About this article

Cite this article

Yakupov, N.M., Giniyatullin, R.R. & Yakupov, S.N. The influence of the character of deformation of structural element surfaces on the corrosive wear. Strength Mater 44, 170–176 (2012). https://doi.org/10.1007/s11223-012-9369-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-012-9369-2