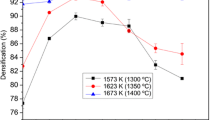

In order to improve the sinterability and thermal shock resistance of ceramic based on MgO magnesium oxide of micron grain size composition is used as the main starting raw material with additions of nano-Al2O3 and nano-SiO2. Ceramic based on MgO is prepared by adding different amounts of Al2O3 and SiO2 to MgO in a molar ratio 1:4. The mixture is molded and sintered in an air atmosphere. Ceramic phase composition and microstructure are studied in an x-ray diffractometer and a scanning electron microscope. The effect of adding different amounts of Al2O3 + 4SiO2 on sinterability and thermal shock resistance of MgO base ceramic is studied. Addition of Al2O3 + 4SiO2 has a favorable effect on test ceramic sinterability and thermal shock resistance. During reaction of solid substances there is formation of magnesia-alumina-spinel and forsterite that leads to retardation of periclase phase grain migration. The degree of specimen compaction is improved and this has a favorable effect on sinterability of ceramic based on MgO. The degree of compaction increases as there is an increase in sintering temperature in the range 1400 to 1500°C. In addition, specimen thermal shock resistance is improved due to connection between microcracks. As a result of adding Al2O3 in an amount up to 30 wt.% + SiO2 in an amount up to 45 wt.% MgO sinterability and thermal shock resistance are improved.

Similar content being viewed by others

References

A. G. M. Othman and N. M. Khalil, “Sintering of magnesia refractories through the formation of periclase-forsterite-spinel phases,” Ceramics Internat., 31, 1117 (2005).

A. G. M. Othman, “Effect of talc and bauxite on sintering, microstructure, and refractory properties of Egyptian dolomitic magnesite,” Brit. Ceramic Trans., 102, 265 (2003).

C. Zhang, D. X. Huang, B. Xu, et al., “Thermal-shock resistance of MgO ceramic,” Rare Metal Mater. Eng., 38, 1207 (2009).

I. Ganesh, S. Bhattacharjee, B. P. Saha, et al., “An efficient MgAl2O4 spinel additive for improved slag erosion and penetration resistance of high-Al2O3 and MgO–C Refractories,” Ceram. Internat., 28, 245 (2002).

I. Ganesh, S. Bhattacharjee, B. P. Saha, et al., “A new sintering aid for magnesium aluminate spinel,” Ceram. Internat., 27, 773 (2001).

I. Ganesh, R. Johnson, G. V. N. Rao, et al., “Microwave-assisted combustion synthesis of nanocrystalline MgAl2O4 spinel powder,” Ceram. Internat., 31, 67 (2005).

J. Szczerba, Z. Pedzich, M. Nikiel, et al., “Influence of raw materials morphology on properties of magnesia-spinel refractories.” J. Europ. Ceram. Soc., 27, 1683 (2007).

A. Saberi, Z. Negahdari, B. Alinejad, et al., “Synthesis and characterization of nanocrystalline forsterite through citrate-nitrate route,” Ceram. Internat., 35, 1705 (2009).

F. N. Cunha-Duncan, H. Balmori-Ramirez, C. C. Sorrell, et al., “Synthetic spinel–forsterite refractory aggregate from the sillimanite minerals,” Minerals Metall. Process., 20, 143 (2003).

F. N. Cunha-Duncan and C. Bradt-Richard, “Synthesis of magnesium aluminate spinels from bauxite and magnesia,” J. Amer. Ceram. Soc., 85, 2995 (2002).

M. T. Li, G. D. Zhang, X. D. Luo, et al., “The preparation and property of ZrO2 / Al2O3 compound ceramics,” Bull, Chinese Ceram. Soc., 34, 1095 (2015).

C. Aksel and P. D. Warren, “Thermal shock parameters (R, R and R) of magnesia–spinel composites,” J. Europ. Ceram. Soc., 23, 301 (2003).

Shinobu Hashimoto, Sawao Honda, Tomoki Hiramatsu, et al., “Fabrication of porous spinel (MgAl2O4) from porous alumina using a template method,” Ceram. Internat., 39, 2077 (2013).

C. Aksel, et al., “Thermal shock behaviour of magnesia–spinel composites,” J. Europ. Ceram. Soc., 24, 2839 (2004).

Research was facilitated by the National Natural Science Fund of China (51402143).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 8, pp. 48 – 54, August, 2016.

Rights and permissions

About this article

Cite this article

Feng, D., Luo, X., Zhang, G. et al. Effect of Al2O3 + 4SiO2 Additives on Sintering Behavior and Thermal Shock Resistance of MgO-Based Ceramics. Refract Ind Ceram 57, 417–422 (2016). https://doi.org/10.1007/s11148-016-9996-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9996-4