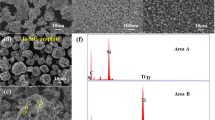

The structure, mechanical properties, and wear-resistance of TiB2–(Fe–Mo) plasma coatings are investigated. Composite powders in the TiB2–(Fe–Mo) system with 20, 40, 60, and 80 wt.% of the Fe–13 wt.% Mo alloy were produced by vacuum sintering with subsequent grinding. The developed powders are conglomerates that contain both refractory and metallic phases. During plasma spraying of developed coatings, a coating with heterophase structure, which consists of Fe-based metal alloy and titanium diboride grains, is formed. The effect of the microstructure of plasmasprayed coatings on the wear-resistance under abrasive wear and dry sliding friction conditions is studied. The scratch hardness testing revealed an insufficient strength of TiB2–20 wt.% (Fe–13 wt.% Mo) coatings and their poor adhesion to the coating base, resulting in the extremely gross wear, when friction. It is found out that, due to the optimal ratio of refractory and metallic phases, the TiB2–40 wt.% (Fe–13 wt.% Mo) coating possesses high wear-resistance under abrasive wear and dry sliding friction conditions.

Similar content being viewed by others

References

Yu. S. Borisov, Yu. A. Kharlamov, S. A. Sidorenko, and Е. N. Arbatovskaya, Powder Material Thermally Sprayed Coatings: Handbook [in Russian], Tekhnika, Kiev (1987), p. 544.

V. N. Antsiferov, G. V. Bobrov, and L. K. Druzhinin, Powder Metallurgy and Sprayed Coatings [in Russian], Metallyrgiya, Moscow (1987), p. 792.

L. Pavlowski, The Science and Engineering of Thermally Sprayed Coatings, John Willey & Sons, Chichester (2008), p. 626.

J. M. Guilemany, J. Nutting, and N. L. Isern, “Microstructural examination of HVOF chromium carbide coatings for high temperature applications,” J. Thermal Spray Technol., No. 5(4), 483–489 (1996).

G. V. Samsonov, L. Ya. Markovskii, A. F. Zhigach, and M. G. Valyashko. Boron: Compounds and Alloys [in Russian], Izd. AN UkrSSR, (1960), p. 590.

J. Horlock, D. G. McCartney, P. H. Shipway, and J. V. Wood, “Thermally sprayed Ni(Cr)–TiB2 coatings using powder produced by self-propagating high temperature synthesis: microstructure and abrasive wear behaviour,” Mater. Sci. Eng., 336, No 5(4), 88–98 (2002).

M. Jones, A. J. Horlock, P. H. Shipway, and D. G. McCartney, “A comparison of the abrasive wear behaviour of HVOF sprayed titanium carbide- and titanium boride-based cermet coatings,” Wear, 251, Nos. 1–2, 1009–1016 (2001).

M. Jones, A. J. Horlock, P. H. Shipway, et al., “Microstructure and abrasive wear behaviour of FeCr–TiC coatings deposited by HVOF spraying of SHS powders,” Wear, 249, Nos. 3–4, 246–253 (2001).

H.-B. Zhu, H. Li, H.-X. Yang, and Z.-X. Li, “Microstructure and sliding wear performance of plasmasprayed TiB2–Ni coating deposited from agglomerated and sintered powder,” J. Thermal Spray Technol., 22, No. 8, 1310–1319 (2001).

Ch. Xiao, H.-T. Wang, G.-C. Ji, et al., “Influence of binder phase content on the microstructure and properties of HVOF-sprayed TiB2–Ni coatings,” J. Mater. Eng., 4, No. 3, 34–40 (2014).

A. P. Umanskii, V. P. Konoval, A. D. Panasyuk, et al., “Plasma coatings of (TiCrC)–(FeCr) composite powder alloys: Structure and properties,” Powder Metall. Metal. Ceram., 46, No. 3, 133–138 (2007).

A. Panasyuk, O. Umanskyi, M. Storozhenko, and V. Akopyan, “Development of TiB2-based cermets with Fe–Mo binder,” Key Eng. Mater., 527, 9–13 (2013).

O. P. Umanskii, V. V. Akopyan, M. S. Storozhenko, et al., Titanium Diboride-Based Composite Wear-Resistant Material. Applicant and Owner: Frantsevich Institute for Problems of Materials Science, National Academy of Sciences of Ukraine. Ukrainian Patent No. 78156. MPK C22C 29/14. u2012 10411; Appl. 03. 09.2012; Publ. 11.03.2013, Bull. No. 5.

A. P. Umanskii, M. S. Storozhenko, V. V. Akopyan, and I. S. Martsenyuk, “Electrospark steel hardening with TiB2–(Fe–Mo) composite materials,” Aviats. Kosmich. Tekh. Tekhnol., 96, No. 9, 214–219 (2012).

A. P. Umanskii, V. V. Akopyan, M. S. Storozhenko, et al., “Structure and properties of detonation coatings of TiB2–(Fe–Mo) composite powders,” Nauk. Notatki, No. 41, 247–253 (2013).

S. R. Ignatovych, I. M. Zakiev, V. I. Zakiev, and S. S. Yutskevych, 3D Noncontact Profilograph. Ukrainian Patent No. 39972 Ukraine. MPK G01B 9/02; 11/30; u200809989; Appl. 01.08.2008; Publ. 25.03.2009; Bull. No. 6; p. 3.

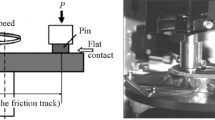

S. R. Ignatovich, I. M. Zakiev, and E. P. Pugachevskaya, “Micro attrition testing machine for materials and coatings,” Probl. Tert. Znosh., No. 50, 50–57 (2008).

E. T. Mamykin, M. K. Kovpak, A. I. Yuga, et al., “A set of machines and a method for determining the bearing characteristics of materials under sliding friction conditions,” Powder Metall. Metal. Ceram., 12, No. 1, 55–58 (1973).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 56, Nos. 1–2 (513), pp. 78–90, 2017.

Rights and permissions

About this article

Cite this article

Storozhenko, M.S., Umanskii, A.P., Terentiev, A.E. et al. Effect of the Structure of TiB2–(Fe–Mo) Plasma Coatings on Mechanical and Tribotechnical Properties. Powder Metall Met Ceram 56, 60–69 (2017). https://doi.org/10.1007/s11106-017-9872-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-017-9872-x