Abstract

Purpose

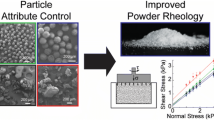

Fine API agglomeration and its mitigation via particle engineering, i.e., dry coating, remains underexplored. The purpose was to investigate agglomeration before and after dry coating of fine cohesive APIs and impact on powder processability, i.e., flowability (FFC), bulk density (BD), and dissolution of BCS Class II drugs.

Method

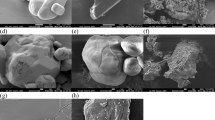

Ibuprofen (three sizes), fenofibrate, and griseofulvin (5–20 µm), before and after dry coating with varying amounts of hydrophobic (R972P) or hydrophilic (A200) nano- silica, were assessed for agglomeration, FFC, BD, surface energy, wettability, and dissolution. The granular Bond number (Bog), a dimensionless parameter, evaluated through material-sparing particle-scale measures and particle-contact models, was used to express relative powder cohesion.

Results

Significant powder processability improvements after dry coating were observed: FFC increased by multiple flow regimes, BD increased by 25–100%, agglomerate ratio (AR) reduction by over an order of magnitude, and greatly enhanced API dissolution rate even with hydrophobic (R972P) silica coating. Scrutiny of particle-contact models revealed non-triviality in estimating API surface roughness, which was managed through the assessment of measured bulk properties. A power-law correlation was identified between AR and Bog and subsequently, between AR and FFC & bulk density; AR below 5 ensured improved processability and dissolution.

Conclusion

Agglomeration, an overlooked material-sparing measure for powder cohesiveness, was a key indicator of powder processability and dissolution. The significant agglomerate reduction was possible via dry coating with either silica type at adequate surface area coverage. Reduced agglomeration after dry coating also countered the adverse impact of increased surface hydrophobicity on dissolution.

Similar content being viewed by others

References

Lipinski C. Poor aqueous solubility - An industry wide problem in drug discovery. American Pharmaceutical Review. 2002;5(3):82–5.

Kalepu S, Nekkanti V. Insoluble drug delivery strategies: Review of recent advances and business prospects. Acta Pharmaceutica Sinica B. 2015;5(5):442–53.

Hu J, Rogers TL, Brown J, Young T, Johnston KP, Williams Iii RO. Improvement of dissolution rates of poorly water soluble APIs using novel spray freezing into liquid technology. Pharm Res. 2002;19(9):1278–84.

Han X, Ghoroi C, To D, Chen Y, Davé R. Simultaneous micronization and surface modification for improvement of flow and dissolution of drug particles. Int J Pharm. 2011;415(1–2):185–95.

da Costa MA, Seiceira RC, Rodrigues CR, Hoffmeister CRD, Cabral LM, Rocha HVA. Efavirenz dissolution enhancement I: Co-micronization. Pharmaceutics. 2013;5(1):1–22.

Bhakay A, Azad M, Bilgili E, Dave R. Redispersible fast dissolving nanocomposite microparticles of poorly water-soluble drugs. Int J Pharm. 2014;461(1–2):367–79.

Krull SM, Susarla R, Afolabi A, Li M, Ying Y, Iqbal Z, Bilgili E, Davé RN. Polymer strip films as a robust, surfactant-free platform for delivery of BCS Class II drug nanoparticles. Int J Pharm. 2015;489(1–2):45–57.

Nase ST, Vargas WL, Abatan AA, McCarthy JJ. Discrete characterization tools for cohesive granular material. Powder Technol. 2001;116(2–3):214–23.

Harnby N. The mixing of cohesive powders. In: Neinow AW, Edwards, M.F., Harnby, N., editor. Mixing in the Process Industries: Second edition Butterworth-Heinemann; 1992. p. 79–96.

Feng JQ, Hays DA. Relative importance of electrostatic forces on powder particles. Powder Technol. 2003;135–136:65–75.

Han X, Jallo L, To D, Ghoroi C, Davé R. Passivation of high-surface-energy sites of milled ibuprofen crystals via dry coating for reduced cohesion and improved flowability. J Pharm Sci. 2013;102(7):2282–96.

Castellanos A. The relationship between attractive interparticle forces and bulk behaviour in dry and uncharged fine powders. Adv Phys. 2005;54(4):263–376.

Yang J, Sliva A, Banerjee A, Dave RN, Pfeffer R. Dry particle coating for improving the flowability of cohesive powders. Powder Technol. 2005;158(1–3):21–33.

Chen Y, Yang J, Dave RN, Pfeffer R. Fluidization of coated group C powders. AIChE J. 2008;54(1):104–21.

Capece M, Huang Z, To D, Aloia M, Muchira C, Davé RN, Yu AB. Prediction of porosity from particle scale interactions: Surface modification of fine cohesive powders. Powder Technol. 2014;254:103–13.

Jallo LJ, Ghoroi C, Gurumurthy L, Patel U, Davé RN. Improvement of flow and bulk density of pharmaceutical powders using surface modification. Int J Pharm. 2012;423(2):213–25.

Huang Z, Scicolone JV, Gurumuthy L, Davé RN. Flow and bulk density enhancements of pharmaceutical powders using a conical screen mill: A continuous dry coating device. Chem Eng Sci. 2015;125:209–24.

De Villiers MM. Influence of agglomeration of cohesive particles on the dissolution behaviour of furosemide powder. Int J Pharm. 1996;136(1–2):175–9.

Huang Z, Xiong W, Kunnath K, Bhaumik S, Davé RN. Improving blend content uniformity via dry particle coating of micronized drug powders. Eur J Pharm Sci. 2017;104:344–55.

Kim S, C. Castillo, M. Sayedahmed, Dave RN. Reduced fine API agglomeration after dry coating for enhanced blend uniformity and processability of low drug loaded blends Pharmaceutical Research. 2022;under review.

Han X, Ghoroi C, Davé R. Dry coating of micronized API powders for improved dissolution of directly compacted tablets with high drug loading. Int J Pharm. 2013;442(1–2):74–85.

Kim S, Bilgili E, Davé RN. Impact of altered hydrophobicity and reduced agglomeration on dissolution of micronized poorly water-soluble drug powders after dry coating. International Journal of Pharmaceutics. 2021;606.

Chen L, Liu J, Zhang Y, Zhang G, Kang Y, Chen A, Feng X, Shao L. The toxicity of silica nanoparticles to the immune system. Nanomedicine. 2018;13(15):1939–62.

Kunnath K, Huang Z, Chen L, Zheng K, Davé R. Improved properties of fine active pharmaceutical ingredient powder blends and tablets at high drug loading via dry particle coating. Int J Pharm. 2018;543(1–2):288–99.

McCarthy JJ, Khakhar DV, Ottino JM. Computational studies of granular mixing. Powder Technol. 2000;109(1–3):72–82.

Yu AB, Feng CL, Zou RP, Yang RY. On the relationship between porosity and interparticle forces. Powder Technol. 2003;130(1–3):70–6.

Chen Y, Jallo L, Quintanilla MAS, Dave R. Characterization of particle and bulk level cohesion reduction of surface modified fine aluminum powders. Colloids Surf, A. 2010;361(1–3):66–80.

Kunnath K, Chen L, Zheng K, Davé RN. Assessing predictability of packing porosity and bulk density enhancements after dry coating of pharmaceutical powders. Powder Technol. 2021;377:709–22.

Rumpf H. Die Wissenschaft des Agglomerierens. Chem Ing Tec. 1974;46(1):1.

Rabinovich YI, Adler JJ, Ata A, Singh RK, Moudgil BM. Adhesion between nanoscale rough surfaces. I. Role of asperity geometry. Journal of Colloid and Interface Science. 2000;232(1):10–16.

Chen Y, Quintanilla MAS, Yang J, Valverde JM, Dave RN. Pull-off force of coated fine powders under small consolidation. Physical Review E - Statistical, Nonlinear, and Soft Matter Physics. 2009;79(4).

Jallo LJ, Chen Y, Bowen J, Etzler F, Dave R. Prediction of inter-particle adhesion force from surface energy and surface roughness. J Adhes Sci Technol. 2011;25(4–5):367–84.

Azad M, Afolabi A, Bhakay A, Leonardi J, Davé R, Bilgili E. Enhanced physical stabilization of fenofibrate nanosuspensions via wet co-milling with a superdisintegrant and an adsorbing polymer. Eur J Pharm Biopharm. 2015;94:372–85.

Freeman R. Measuring the flow properties of consolidated, conditioned and aerated powders - A comparative study using a powder rheometer and a rotational shear cell. Powder Technol. 2007;174(1–2):25–33.

Schulze D, Schwedes J, Carson JW. Powders and bulk solids: Behavior, characterization, storage and flow; 2008.

Chen L, Ding X, He Z, Fan S, Kunnath KT, Zheng K, Davé RN. Surface engineered excipients: II. Simultaneous milling and dry coating for preparation of fine-grade microcrystalline cellulose with enhanced properties. International Journal of Pharmaceutics. 2018;546(1–2):125–136.

Jallo LJ, Dave RN. Explaining Electrostatic Charging and Flow of Surface-Modified Acetaminophen Powders as a Function of Relative Humidity Through Surface Energetics. J Pharm Sci. 2015;104(7):2225–32.

Wu S. Polar and nonpolar interactions in adhesion. J Adhes. 1973;5(1):39–55.

Barra J, Lescure F, Falson-Rieg F, Doelker E. Can the organization of a binary mix be predicted from the surface energy, cohesion parameter and particle size of its components? Pharm Res. 1998;15(11):1727–36.

Zheng K, Kunnath K, Ling Z, Chen L, Davé RN. Influence of guest and host particle sizes on dry coating effectiveness: When not to use high mixing intensity. Powder Technol. 2020;366:150–63.

Alway B, Sangchantra R, Stewart PJ. Modelling the dissolution of diazepam in lactose interactive mixtures. Int J Pharm. 1996;130(2):213–24.

Chander S, Hogg R, Fuerstenau DW. Characterization of the wetting and dewetting behavior of powders. Kona Powder Part J. 2007;25(March):56–75.

Washburn EW. The dynamics of capillary flow. Phys Rev. 1921;17(3):273–83.

Thakker M, Karde V, Shah DO, Shukla P, Ghoroi C. Wettability measurement apparatus for porous material using the modified Washburn method. Measurement Science and Technology. 2013;24(12).

Sievens-Figueroa L, Pandya N, Bhakay A, Keyvan G, Michniak-Kohn B, Bilgili E, Davé RN. Using USP i and USP IV for discriminating dissolution rates of nano- and microparticle-loaded pharmaceutical strip-films. AAPS PharmSciTech. 2012;13(4):1473–82.

Bolten D, Lietzow R, Türk M. Solubility of ibuprofen, phytosterol, salicylic acid, and naproxen in aqueous solutions. Chem Eng Technol. 2013;36(3):426–34.

Rao VM, Lin M, Larive CK, Southard MZ. A mechanistic study of griseofulvin dissolution into surfactant solutions under laminar flow conditions. J Pharm Sci. 1997;86(10):1132–7.

Chattoraj S, Shi L, Sun CC. Profoundly improving flow properties of a cohesive cellulose powder by surface coating with nano-silica through comilling. J Pharm Sci. 2011;100(11):4943–52.

Massimilla L, Donsì G. Cohesive forces between particles of fluid-bed catalysts. Powder Technol. 1976;15(2):253–60.

Witten TA, Sander LM. Diffusion-limited aggregation, a kinetic critical phenomenon. Phys Rev Lett. 1981;47(19):1400–3.

Matsoukas T, Friedlander SK. Dynamics of aerosol agglomerate formation. Journal of Colloid And Interface Science. 1991;146(2):495–506.

Wu MK, Friedlander SK. Note on the power law equation for fractal-like aerosol agglomerates. Journal of Colloid And Interface Science. 1993;159(1):246–8.

Qu L, Zhou Q, Denman JA, Stewart PJ, Hapgood KP, Morton DAV. Influence of coating material on the flowability and dissolution of dry-coated fine ibuprofen powders. Eur J Pharm Sci. 2015;78:264–72.

Peppas NA. Analysis of Fickian and non-Fickian drug release from polymers. Pharm Acta Helv. 1985;60(4):110–1.

Ritger PL, Peppas NA. A simple equation for description of solute release I. Fickian and non-fickian release from non-swellable devices in the form of slabs, spheres, cylinders or discs. Journal of Controlled Release. 1987;5(1):23–36.

Peppas NA, Sahlin JJ. A simple equation for the description of solute release. III. Coupling of diffusion and relaxation. International Journal of Pharmaceutics. 1989;57(2):169–172.

ACKNOWLEDGMENTS AND DISCLOSURES

The authors thank Hira Khurshid for her assistance in sample preparation and testing from, and Roopal Bhat, Christopher Kossor, and Siddharth Tripathi for their editorial input. The authors have no conflicts of interest or sources of competing interest to declare. Partial support for this work from IFPRI is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, S., Cheikhali, M. & Davé, R.N. Decoding Fine API Agglomeration as a Key Indicator of Powder Flowability and Dissolution: Impact of Particle Engineering. Pharm Res 39, 3079–3098 (2022). https://doi.org/10.1007/s11095-022-03293-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-022-03293-z