ABSTRACT

Purpose

In this study, the electrospinnability of poly(lactic-co-glycolic acid) (PLGA) solutions was investigated, with a focus on understanding the influence of molecular weight of PLGA, solvent type and solvent composition on the physical properties of electrospun nanofibers.

Method

Various solvents were tested to dissolve two PLGA grades (50 KDa-RG755, 100 KDa-RG750). The viscoelasticity, surface tension, and evaporation rate of the PLGA solutions were characterized prior to the electrospinning process. The resulting electrospun nanofibers were characterized with respect to the morphology and mechanical properties.

Results

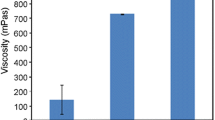

Two pairs of solvent mixtures, i.e. dimethylformamide (DMF)—tetrahydrofuran (THF) and DMF—chloroform (CHL), were identified to provide a stable cone-jet. Within the polymer concentration range studied (10–30%, w/v), RG750 solutions could be electrospun into uniform fibers at 30% (w/v) or at 20% (w/v) when modifying the solvent composition. In comparison to DMF-THF solution, fibers had larger diameter, higher stiffness and tensile strength when electrospun from DMF-CHL solution.

Conclusion

The high molecular weight polymer could ensure sufficient intermolecular interaction to generate uniform fibers. The solvent could influence the morphology and mechanical properties of the electrospun fibers by altering the properties of PLGA solution, and drying rate of fibers in the electrospinning process.

Similar content being viewed by others

Abbreviations

- [η]:

-

Intrinsic viscosity

- C*:

-

Overlap concentration

- CHL:

-

Chloroform

- DMF:

-

Dimethylformamide

- ECM:

-

Extracellular matrix

- G′:

-

Storage modulus

- G″:

-

Loss modulus

- GA:

-

Glycolic acid

- LA:

-

Lactic acid

- LVR:

-

Linear viscoelastic region

- Mc :

-

Critical molecular weight

- MW:

-

Molecular weight

- PEG:

-

Polyethylene glycol

- PEO:

-

Polyethylene oxide

- PET-co-PEI:

-

Poly(ethylene terephthalate-co-ethylene isophthalate)

- PGA:

-

Polyglycolic acid

- PLA:

-

Polylactic acid

- PLGA:

-

Poly(lactic-co-glycolic acid)

- Rcoil :

-

Polymer coil radius

- SEM:

-

Scanning electron microscope

- t:

-

Time of flow of the polymer solution

- t0 :

-

Time of flow of the solvent solution

- TGA:

-

Thermogravimetric analysis

- THF:

-

Tetrahydrofuran

- ηrel :

-

Relative viscosity

- ηsp :

-

Specific viscosity

REFERENCES

Dhandayuthapani B, Yoshida Y, Maekawa T, Kumar DS. Polymeric scaffolds in tissue engineering application: a review. Int J Polym Sci. 2011;2011:1–19.

Jose MV, Thomas V, Johnson KT, Dean DR, Nyairo E. Aligned PLGA/HA nanofibrous nanocomposite scaffolds for bone tissue engineering. Acta Biomater. 2009;5(1):305–15.

Cooper JA, Lu HH, Ko FK, Freeman JW, Laurencin CT. Fiber-based tissue-engineered scaffold for ligament replacement: design considerations and in vitro evaluation. Biomaterials. 2005;26(13):1523–32.

Chou SF, Carson D, Woodrow KA. Current strategies for sustaining drug release from electrospun nanofibers. J Control Release. 2015;220(Pt B):584–91.

Goonoo N, Bhaw-Luximon A, Jhurry D. Drug loading and release from electrospun biodegradable nanofibers. J Biomed Nanotechnol. 2014;10(9):2173–99.

Boateng J, Catanzano O. Advanced therapeutic dressings for effective wound healing—a review. J Pharm Sci. 2015;104(11):3653–80.

Rieger KA, Birch NP, Schiffman JD. Designing electrospun nanofiber mats to promote wound healing—a review. J Mater Chem B. 2013;1(36):4531.

Szentivanyi AL, Zernetsch H, Menzel H, Glasmacher B. A review of developments in electrospinning technology: new opportunities for the design of artificial tissue structures. Int J Artif Organs. 2011;34(10):986–97.

Theron JP, Knoetze JH, Sanderson RD, Hunter R, Mequanint K, Franz T, et al. Modification, crosslinking and reactive electrospinning of a thermoplastic medical polyurethane for vascular graft applications. Acta Biomater. 2010;6(7):2434–47.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28(3):325–47.

Christanti Y, Walker LM. Surface tension driven jet break up of strain-hardening polymer solutions. J Non-Newtonian Fluid Mech. 2001;100(1):9–26.

Zhu X, Cui W, Li X, Jin Y. Electrospun fibrous mats with high porosity as potential scaffolds for skin tissue engineering. Biomacromolecules. 2008;9(7):1795–801.

Li WJ, Laurencin CT, Caterson EJ, Tuan RS, Ko FK. Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Mater Res. 2002;60(4):613–21.

Prabaharan M, Jayakumar R, Nair S. Biomedical applications of polymeric nanofibers. In: Springer; 2012.

Freyman T, Yannas I, Gibson L. Cellular materials as porous scaffolds for tissue engineering. Prog Mater Sci. 2001;46(3):273–82.

Shenoy SL, Bates WD, Frisch HL, Wnek GE. Role of chain entanglements on fiber formation during electrospinning of polymer solutions: good solvent, non-specific polymer–polymer interaction limit. Polymer. 2005;46(10):3372–84.

Kong L, Ziegler GR. Role of molecular entanglements in starch fiber formation by electrospinning. Biomacromolecules. 2012;13(8):2247–53.

Shin Y, Hohman M, Brenner M, Rutledge G. Experimental characterization of electrospinning: the electrically forced jet and instabilities. Polymer. 2001;42(25):09955–67.

McKee MG, Hunley MT, Layman JM, Long TE. Solution rheological behavior and electrospinning of cationic polyelectrolytes. Macromolecules. 2006;39(2):575–83.

Gandhi K, Williams MC. Solvent effects on the viscosity of moderately concentrated polymer solutions. In: Journal of Polymer Science Part C: Polymer Symposia: Wiley Online Library; 1971. p. 211–234.

Isono Y, Fujimoto T, Inagaki H, Shishido M, Nagasawa M. Viscoelastic properties of branched polymers. I. At the undiluted state. Polym J. 1980;12(2):131–7.

Isono Y, Fujimoto T, Kajiura H, Nagasawa M. Viscoelastic properties of branched polymers. II in concentrated solutions. Polym J. 1980;12(6):369–78.

Graessley WW. The entanglement concept in polymer rheology. In: The entanglement concept in polymer rheology. Springer; 1974. p. 1–179.

Kong L, Ziegler GR. Rheological aspects in fabricating pullulan fibers by electro-wet-spinning. Food Hydrocoll. 2014;38:220–6.

Kong L, Ziegler GR. Fabrication of pure starch fibers by electrospinning. Food Hydrocoll. 2014;36:20–5.

Klossner RR, Queen HA, Coughlin AJ, Krause WE. Correlation of chitosan’s rheological properties and its ability to electrospin. Biomacromolecules. 2008;9(10):2947–53.

McKee MG, Wilkes GL, Colby RH, Long TE. Correlations of solution rheology with electrospun fiber formation of linear and branched polyesters. Macromolecules. 2004;37(5):1760–7.

Yu JH, Fridrikh SV, Rutledge GC. The role of elasticity in the formation of electrospun fibers. Polymer. 2006;47(13):4789–97.

Pandey A, Jain DS. Poly Lactic‐Co‐Glycolic Acid (PLGA) copolymer and its pharmaceutical application. Handbook of polymers for pharmaceutical technologies: processing and applications, volume 2. 2015.p. 151–172.

Singh G, Kaur T, Kaur R, Kaur A. Recent biomedical applications and patents on biodegradable polymer-PLGA. Int J Pharmacol Pharm Sci. 2014;1:30–42.

Chang N-J, Lam C-F, Lin C-C, Chen W-L, Li C-F, Lin Y-T, et al. Transplantation of autologous endothelial progenitor cells in porous PLGA scaffolds create a microenvironment for the regeneration of hyaline cartilage in rabbits. Osteoarthr Cartil. 2013;21(10):1613–22.

Sahoo S, Toh SL, Goh JC. A bFGF-releasing silk/PLGA-based biohybrid scaffold for ligament/tendon tissue engineering using mesenchymal progenitor cells. Biomaterials. 2010;31(11):2990–8.

Hong Y, Fujimoto K, Hashizume R, Guan J, Stankus JJ, Tobita K, et al. Generating elastic, biodegradable polyurethane/poly (lactide-co-glycolide) fibrous sheets with controlled antibiotic release via two-stream electrospinning. Biomacromolecules. 2008;9(4):1200–7.

Baldursdóttir SG, Kjøniksen A-L, Karlsen J, Nyström B, Roots J, Tønnesen HH. Riboflavin-photosensitized changes in aqueous solutions of alginate. Rheological studies. Biomacromolecules. 2003;4(2):429–36.

Gomes D, Borges C, Pinto J. Evaluation of parameter uncertainties during the determination of the intrinsic viscosity of polymer solutions. Polymer. 2000;41(14):5531–4.

Møller P, Fall A, Bonn D. Origin of apparent viscosity in yield stress fluids below yielding. EPL. 2009;87(3):38004.

Mezger TG. The rheology handbook: for users of rotational and oscillatory rheometers: Vincentz Network. 2006.

Morrison FA. Understanding rheology. USA: Oxford University Press; 2001.

Elliott PT, Steffenhagen MJ, Glass JE. Spray applications: Part III. Assessment of viscosities at high shear rates and dynamic uniaxial extensional viscosities on fan nozzle air sprayability. J Coat Technol Res. 2007;4(4):341–9.

Crooks R, Cooper-White J, Boger DV. The role of dynamic surface tension and elasticity on the dynamics of drop impact. Chem Eng Sci. 2001;56(19):5575–92.

Kennedy JC, Meadows J, Williams PA. Shear and extensional viscosity characteristics of a series of hydrophobically associating polyelectrolytes. J Chem Soc Faraday Trans. 1995;91(5):911–6.

ACKNOWLEDGMENTS AND DISCLOSURES

This study was supported, in part, by Graduate School of Health and Medical Sciences of University of Copenhagen, Department of Pharmacy of University of Copenhagen, Department of Chemical Engineering, Biotechnology and Environmental Technology of University of Southern Denmark, Technology and Production Sciences (FTP, Project 12-126515/0602-02670B) and the Danish Council for Independent Research (DFF).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(DOCX 203 kb)

Rights and permissions

About this article

Cite this article

Liu, X., Baldursdottir, S.G., Aho, J. et al. Electrospinnability of Poly Lactic-co-glycolic Acid (PLGA): the Role of Solvent Type and Solvent Composition. Pharm Res 34, 738–749 (2017). https://doi.org/10.1007/s11095-017-2100-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-017-2100-z