Abstract

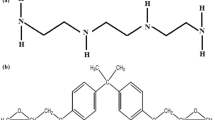

Several epoxy Al(OH)O (boehmite) dispersions in an epoxy resin are produced in a kneader to study the mechanistic correlation between the nanoparticle size and mechanical properties of the prepared nanocomposites. The agglomerate size is set by a targeted variation in solid content and temperature during dispersion, resulting in a different level of stress intensity and thus a different final agglomerate size during the process. The suspension viscosity was used for the estimation of stress energy in laminar shear flow. Agglomerate size measurements are executed via dynamic light scattering to ensure the quality of the produced dispersions. Furthermore, various nanocomposite samples are prepared for three-point bending, tension, and fracture toughness tests. The screening of the size effect is executed with at least seven samples per agglomerate size and test method. The variation of solid content is found to be a reliable method to adjust the agglomerate size between 138–354 nm during dispersion. The size effect on the Young’s modulus and the critical stress intensity is only marginal. Nevertheless, there is a statistically relevant trend showing a linear increase with a decrease in agglomerate size. In contrast, the size effect is more dominant to the sample’s strain and stress at failure. Unlike microscaled agglomerates or particles, which lead to embrittlement of the composite material, nanoscaled agglomerates or particles cause the composite elongation to be nearly of the same level as the base material. The observed effect is valid for agglomerate sizes between 138–354 nm and a particle mass fraction of 10 wt%.

Similar content being viewed by others

References

Al-Turaif HA (2010) Effect of nano TiO2 particle size on mechanical properties of cured epoxy resin. Prog Org Coat 69:241–246. doi:10.1016/j.porgcoat.2010.05.011

Bittmann B, Haupert F, Schlarb AK (2009) Ultrasonic dispersion of inorganic nanoparticles in epoxy resin. Ultrason Sonochem 16:622–628. doi:10.1016/j.ultsonch.2009.01.006

Evans AG (1972) The strength of a brittle material containing second phase dispersions. PHIL MAG A 26(6):1327–1344. doi:10.1080/14786437208220346

Exner W, Arlt C, Mahrholz T, Riedel U, Sinapius M (2012) Nanoparticles with various surface modifications as functionalized cross-linking agents for composite resin materials. Compos Sci Technol 72:1153–1159. doi:10.1016/j.compscitech.2012.03.024

Faber KT, Evans AG (1983a) Crack deflection processes—I. Theory ACTA METALL 31(4):565–576. doi:10.1016/0001-6160(83)90046-9

Faber KT, Evans AG (1983b) Crack deflection processes—II. Experiment ACTA METALL 31(4):577–584. doi:10.1016/0001-6160(83)90047-0

Fankhänel J, Silbernagl D, Ghasem Zadeh Khorasani M et al (2016) Mechanical properties of boehmite evaluated by atomic force microscopy experiments and molecular dynamic finite element simulations. J Nanomater 2016(2016):1–13. doi:10.1155/2016/5017213

Fu SY, Feng XQ, Lauke B, Mai YW (2008) Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. COMPOS PART B-ENG 39:933–961. doi:10.1016/j.compositesb.2008.01.002

Green DJ, Nicholson PS, Embury JD (1979) Fracture of a brittle particulate composite. J Mater Sci 14:1413–1420. doi:10.1007/BF00549316

Hall JN, Jones JW, Sachdev AK (1994) Particle size, volume fraction and matrix strength effects on fatigue behavior and particle fracture in 2124 aluminum-SiCp composites. Mater Sci Eng A183:69–80

Jamaati R, Mohammad RT, Hossein E, Mohammad RS (2014) Comparison of microparticles and nanoparticles effects on the microstructure and mechanical properties of steel-based composite and nanocomposite fabricated via accumulative roll bonding process. MATER DESIGN 56:359–367. doi:10.1016/j.matdes.2013.11.049

Johnsen BB, Kinloch AJ, Mohammend RD, Taylor AC, Sprenger S (2007) Toughening mechanisms of nanoparticle-modified epoxy polymers. Polymer 48:530–541. doi:10.1016/j.polymer.2006.11.038

Kinloch AJ, Mohammed RD, Taylor AC, Eger C, Sprenger S, Egan D (2005) The effect of silica nano particles and rubber particles on the toughness of multiphase thermosetting epoxy polamers. J Mater Sci 40:5083–5086. doi:10.1007/s10853-005-1716-2

Kinloch AJ, Maxwell D, Young RJ (1985) Micromechanisms of crack propagation in hybrid-particulate composites. J Mater Sci Lett 4:1276–1279. doi:10.1007/BF00723480

Kinloch AJ, Williams JG (1980) Crack blunting mechanisms in polymers. J Mater Sci 15:987–996. doi:10.1007/BF00552112

Knieke C et al (2010) Nanoparticle production with stirred-media mills: opportunities and limits. Chem Eng Technol 33:1401–1411. doi:10.1002/ceat.201000105

Lange FF, Radford KC (1971) Fracture energy of an epoxy composite system. J Mater Sci 6:1197–1203. doi:10.1007/BF00550091

Lange FF (1970) The interaction of a crack front with a second-phase dispersion. PHIL MAG A 22(179):983–992. doi:10.1080/14786437008221068

Nakamura Y, Yamaguchi M, Okubo M, Matsumoto T (1992) Effects of particle size on mechanical and impact properties of epoxy resin filled with spherical silica. J Appl Polym Sci 45:1281–1289. doi:10.1002/app.1992.070450716

Nolte H, Schilde C, Kwade A (2012) Determination of particle size distributions and the degree of dispersion in nanocomposites. Compos Sci Technol 72:948–958. doi:10.1016/j.compscitech.2012.03.010

Nolte H, Schilde C, Kwade A (2010) Production of highly loaded nanocomposites by dispersing nanoparticles in epoxy resin. Chem Eng Technol 33:1447–1455. doi:10.1002/ceat.201000096

Radford KC (1971) The mechanical properties of an epoxy resin with a second phase dispersion. J Mater Sci 6:1286–1291. doi:10.1007/BF00552042

Reichert H, Ruhmling K (1976) Misch- und Desagglomerationskinetik beim Kneten von Pigmentpasten. CHEM-ING-TECH 46:559–587. doi:10.1002/cite.330480618

Rumpf H (1959) Beanspruchungstheorie der Prallzerkleinerung. Chemie Ingenieur Technik 31(5):323–337

Rumpf H, Raasch J (1962) Desagglomeration in Strömungen. European symposium on size reduction (1st:Frankfurt a.M.:151-159)

Schilde C, Kampen I, Kwade A (2010) Dispersion kinetics of nano-sized particles for different dispersing machines. Chem Eng Sci 65:3518–3527. doi:10.1016/j.ces.2010.02.043

Singh RP, Zhang M, Chan D (2002) Toughening of a brittle thermosetting polymer: effects of reinforcement particle size and volume fraction. J Mater Sci 37:781–788. doi:10.1023/A:1013844015493

Torno O (2008) Dispergierbare Böhmite aus Alkoxidprozess. Science Day 2008 Nano-Techno-Science in Composite Structures and Adaptive Systems

Wetzel B, Rosso P, Haupert F, Friedrich K (2006) Epoxy nanocomposites—fracture and toughening mechanisms. Eng Fract Mech 73(16):2375–2398. doi:10.1016/j.engfracmech.2006.05.018

Acknowledgements

This study developed in the framework of the research unit FOR2021 “Acting Principles of Nano-Scaled Matrix Additives for Composite Structures”. The authors are exceedingly grateful to the German Research Foundation (DFG) for the financial support, to Dr. Patrick Bussian (Sasol Germany GmbH) for providing the particulate material, to Peter Pfeiffer (TU Braunschweig) for the SEM pictures, and to Carmen Westphal and Marcus Kubicka for their technical support concerning the mechanical testing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by the German Research Foundation (DFG).

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jux, M., Finke, B., Mahrholz, T. et al. Effects of Al(OH)O nanoparticle agglomerate size in epoxy resin on tension, bending, and fracture properties. J Nanopart Res 19, 139 (2017). https://doi.org/10.1007/s11051-017-3831-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-017-3831-9