Abstract

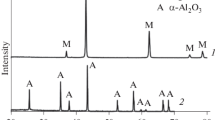

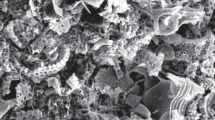

In this paper, through thermal analysis of the melting process of foamed ceramics, the microstructure evolution of foamed ceramics and the effect mechanism of the appearance of gas–solid interface on the evolution of pore wall structure are studied. A new method for regulating the microstructure of pore wall based on gas–solid interface is proposed. The results show that after the initial melting temperature point, the appearance of the gas–solid interface provides a large number of heterogeneous nucleation sites, which promotes the precipitation of anorthite in the pore wall. Within the soaking time of 0–50 min, the gas–solid interface showed a decreasing trend, which resulted in a significant decrease in the anorthite content on the pore wall and eventually disappeared. The addition of alkali metal oxide-Na2O not only reduces the melting point of the raw material, but also increases the number of gas–solid interfaces, thereby increasing the content of anorthite in the pore wall. When the Na2O content reaches 2.1 mass%, the effect of the gas–solid interface is significantly reduced. Na2O reacts with quartz to form a sodium silicate melt, at the same time, the addition of Na2O provides excess O2−. The Mg2+ and Al3+ in the raw material combine with free O2− to form spinel, which promotes the spinel precipitation in the pore wall, leading to the main crystalline phase from anorthite to spinel. This research has important guiding significance for enriching and precisely controlling the preparation process of porous materials.

Similar content being viewed by others

Reference

Fen Y, Long C, Yongchuang L, Kunqiong L, Chenchen L, Kecai L, Hao C. Research status and prospect of foamed ceramics. Guangzhou Chem Ind. 2017;45:9-10+41.

Ning D, Hao C, Jing L. Research on application technology and prospect of foamed ceramic insulation board. Jiangsu Build. 2013;4:100–2.

Dong Hu, Kun Li, Fuxing S. Preparation of high strength homogeneous foam glass. Chin Ceram. 2015;51:60–73.

Ma B, Chang S, Ren X, Gao Z, Qian F, Yang W, Liu G, Li H, Jingkun Y, Zhu Q. Preparation and properties of porous mullite ceramics with high-closed porosity and high strength from fly ash via reaction synthesis process. J Alloys Compd. 2019;803:981–91.

Mingkai Z, Lifen P, Huaide W, Kaiwen H. The effect of ferric oxide and foaming agent on the properties of coal gangue closed-cell foamed ceramics. 2015; 51:77–80.

Kyaw Oo D’Amore G, Caniato M, Travan A, Turco G, Marsich L, Ferluga A, Schmid C. Innovative thermal and acoustic insulation foam from recycled waste glass powder. Clean Prod. 2017;165:1306–15.

Ivanov KS. Preparation and properties of foam glass-ceramic from diatomite. Wuhan Univ Technol Mater Sci Ed. 2018;33:273–7.

Liu J, Ren B, Rong Y, Yi Zhao L, Wang YL, Wang C, Sang G, Yang Ji. Highly porous alumina cellular ceramics bonded by in-situ formed mullite prepared by gelation-assisted Al2O3–Si particle-stabilized foams. Ceram Int. 2020;278:0272–8842.

Xian Z, Zeng L, Cheng X, Wang H. Effect of polishing waste additive on microstructure and foaming property of porcelain tile and linetics of sinter-crystallization. Therm Anal Calorim. 2015;122:997–1004.

Zhou MK, Ge XX, Wang HD, Chen LS, Chen X. Effect of the CaO content and decomposition of calcium-containing minerals on properties and microstructure of ceramic foams from fly ash. Ceram Int. 2017;43:9451–7.

Ercenk E. The effect of clay on foaming and mechanical properties of glass foaming insulating material. Therm Anal Calorim. 2017;127:137–46.

Zou C, Cao J, Zhao M, Wang Z, Jinshan L. Combined sodium and fluorine promote diopside continuous growth to achieve one-step crystallization in CaO-Al2O3-SiO2-Fe2O3 glass-ceramics. J Eur Ceram Soc. 2019;39:4979–87.

Zhao M, Cao J, Wang Z, Li G. Precipitating spinel into precursor glass and its assistance in crystallization. J Eur Ceram Soc. 2019;39:2427–35.

Li X, Zhou G, Yang Q, Zhu X, Ren G, Liu L. Preparation and performance of electromagnetic wave absorbing foamed ceramics with high closed porosity and gradient SiC distribution. Ceram Int. 2020;46:2294–9.

Li C, Zhou Y, Tian Y, Zhao Y, Wang K, Li G, Chai Y. Preparation and characterization of mullite whisker reinforced ceramicsmade from coal fly ash. Ceram Int. 2019;45:5613–6.

Rashad M, Balasubramanian M. Characteristics of porous mullite developed from clay and AlF3·3H2O. J Eur Ceram Soc. 2018;38:3673–80.

Cao J, Jinshan L, Jiang L, Wang Z. Sinterability, microstructure and compressive strength of porous glass-ceramics from metallurgical silicon slag and waste glass. Ceram Int. 2016;42:10079–84.

Da Silva RC, Kubaski ET, Tenório-Neto ET, Lima-Tenório MK, Tebcherani SM. Foam glass using sodium hydroxide as foaming agent: Study on the reaction mechanism in soda-lime glass matrix. J Non-Crystalline Solids. 2019;511:177–82.

Meng Z, Yang D, Yan Y. Study of carbon black oxidation behavior under different heating rates. Therm Anal Calorim. 2014;118:551–9.

Ren X, Ma B, Zhang Y, Zhu Q, Li D, Li S, Yuan L, Jingkun Y, Liu G, Li H. Effects of sintering temperature and V2O5 additive on the properties of SiC-Al2O3 ceramic foams. J Alloys Compd. 2018;732:716–24.

Hongming Z, Minghui C, Jian L. Effect of Na2O on microstructure and properties of MgO-Al2O3-B2O3-SiO2 microcrystalline glass. Chin Ceram. 2019;55:44–9.

Acknowledgements

This work was funded by the National Key R&D Program of China (2018YFC1901806) and Key R&D Program of Hebei Province (20373807D).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Cao, J., Xu, B. et al. Effect of gas–solid interface on pore wall microstructure evolution during thermal melting of foamed ceramics. J Therm Anal Calorim 147, 2035–2046 (2022). https://doi.org/10.1007/s10973-021-10585-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10585-w