Abstract

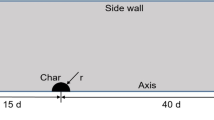

Gasification models of a char particle based on the true porous structure are essential for the accurate simulation of gasifiers, and pore-scale study might provide important information for the development of the porous char particle gasification models. In this paper, a numerical study was conducted on the gasification of a single-pore char particle in supercritical water, and the emphasis was put on the gasification process inside the pore with the effects of surrounding fluid, pore structure and pore position considered. The results showed that the gasification in a pore was quite affected by pore diffusion. The increase in temperature and particle Reynolds number promoted the gasification in the pore, and convection mainly enhanced the heat transfer but had limited promotion on mass transfer in kinetically controlled regime. Increasing pore length and decreasing pore diameter caused the increase in diffusion resistance and the former had more obvious effects. However, the decreased pore diameter increased the specific surface area and benefited the whole char conversion. The pore position affected the species distribution inside the pore for non-diffusive gasification, and the impact was limited in kinetically controlled regime. Finally, study in this work will be further extended to the gasification of the porous char particle.

Similar content being viewed by others

References

Zhao Y, Yang J, Ma S, Zhang S, Liu H, Gong B, et al. Emission controls of mercury and other trace elements during coal combustion in China: a review. Int Geol Rev. 2018;60(5–6):638–70.

Fan C, Jin H, Shang F, Feng H, Sun J. Study on the surface structure development of porous char particles in catalytic supercritical water gasification process. Fuel Process Technol. 2019;193:73–81. https://doi.org/10.1016/j.fuproc.2019.04.029.

Yuan J, Na C, Lei Q, Xiong M, Guo J, Hu Z. Coal use for power generation in China. Resour Conserv Recycl. 2018;129:443–53.

Jin H, Lu Y, Liao B, Guo L, Zhang X. Hydrogen production by coal gasification in supercritical water with a fluidized bed reactor. Int J Hydrog Energy. 2010;35(13):7151–60.

Bai B, Liu Y, Zhang H, Zhou F, Han X, Wang Q, et al. Experimental investigation on gasification characteristics of polyethylene terephthalate (PET) microplastics in supercritical water. Fuel. 2020;262:116630.

Guo L, Jin H, Lu Y. Supercritical water gasification research and development in China. J Supercrit Fluids. 2015;96:144–50.

Fan C, Guo S, Jin H. Numerical study on coal gasification in supercritical water fluidized bed and exploration of complete gasification under mild temperature conditions. Chem Eng Sci. 2019;206:134–45.

Bai B, Liu Y, Wang Q, Zou J, Zhang H, Jin H, et al. Experimental investigation on gasification characteristics of plastic wastes in supercritical water. Renew Energy. 2019;135:32–40.

Jin H, Fan C, Guo L, Liu S, Cao C, Wang R. Experimental study on hydrogen production by lignite gasification in supercritical water fluidized bed reactor using external recycle of liquid residual. Energy Convers Manag. 2017;145:214–9. https://doi.org/10.1016/j.enconman.2017.04.102.

Mermoud F, Golfier F, Salvador S, Van de Steene L, Dirion J-L. Experimental and numerical study of steam gasification of a single charcoal particle. Combust Flame. 2006;145(1–2):59–79.

Schulze S, Nikrityuk P, Compart F, Richter A, Meyer B. Particle-resolved numerical study of char conversion processes in packed beds. Fuel. 2017;207:655–62.

Xiong Q, Kong S-C. High-resolution particle-scale simulation of biomass pyrolysis. ACS Sustain Chem Eng. 2016;4(10):5456–61.

Bozorg MV, Doranehgard MH, Hong K, Xiong Q. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil–Al2O3 nanofluid. Renew Energy. 2020;145:2598–614.

Ren F, Xiang L-K, Chu H-Q, Ya Y-C, Han W-W, Nie X-K. Numerical investigation on the effect of CO2 and steam for the H2 intermediate formation and NOX emission in laminar premixed methane/air flames. Int J Hydrog Energy. 2020;45:3785–94.

Izadi A, Siavashi M, Xiong Q. Impingement jet hydrogen, air and CuH2O nanofluid cooling of a hot surface covered by porous media with non-uniform input jet velocity. Int J Hydrog Energy. 2019;44(30):15933–48.

Li D, Gao R, Dong L, Lam WK, Zhang F. A novel 3D re-entrant unit cell structure with negative Poisson’s ratio and tunable stiffness. Smart Mater Struct. 2019. https://doi.org/10.1088/1361-665X/ab6696/meta.

Kestel M, Nikrityuk P, Hennig O, Hasse C. Numerical study of the partial oxidation of a coal particle in steam and dry air atmospheres. IMA J Appl Math. 2012;77(1):32–46.

Higuera F. Combustion of a coal char particle in a stream of dry gas. Combust Flame. 2008;152(1–2):230–44.

Ha MY, Choi BR. A numerical study on the combustion of a single carbon particle entrained in a steady flow. Combust Flame. 1994;97(1):1–16.

Jin H, Fan C, Guo L, Zhao X, Cao C, Wei W. Pore structure and its evolution in char during supercritical water gasification process. J Porous Med. 2019;22(2):195–207.

Richter A, Nikrityuk PA, Kestel M. Numerical investigation of a chemically reacting carbon particle moving in a hot O2/CO2 atmosphere. Ind Eng Chem Res. 2013;52(16):5815–24.

Xue Z, Guo Q, Gong Y, Xu J, Yu G. Numerical study of a reacting single coal char particle with different pore structures moving in a hot O2/CO2 atmosphere. Fuel. 2017;206:381–9.

Fong GH, Jorgensen S, Singer SL. Pore-resolving simulation of char particle gasification using micro-CT. Fuel. 2018;224:752–63.

Turns SR. An introduction to combustion. New York: McGraw-Hill; 1996.

Sundaresan S, Amundson NR. Diffusion and reaction in a stagnant boundary layer about a carbon particle. 5. Pseudo-steady-state structure and parameter sensitivity. Ind Eng Chem Fundam. 1980;19(4):344–51.

Wagner W, Cooper JR, Dittmann A, Kijima J, Kretzschmar H-J, Kruse A, et al. The IAPWS industrial formulation 1997 for the thermodynamic properties of water and steam. J Eng Gas Turbines Power. 2000;122(1):150–84. https://doi.org/10.1115/1.483186.

Zhao X, Jin H, Chen Y, Ge Z. Numerical study of H2, CH4, CO, O2 and CO2 diffusion in water near the critical point with molecular dynamics simulation. Comput Math Appl. 2019. https://doi.org/10.1016/j.camwa.2019.11.012.

Krishnamoorthy G, Rawat R, Smith PJ. Parallelization of the p-1 radiation model. Numer Heat Transf Part B Fundam. 2006;49(1):1–17.

Ren Z, Guo L, Jin H, Luo K (eds.). Integration of CFD codes and radiation model for supercritical water gasification of coal in fluidized bed reactor. In: International heat transfer conference digital library; 2018: Begel House Inc.

Gao X, Zhang Y, Li B, Zhao Y, Jiang B. Determination of the intrinsic reactivities for carbon dioxide gasification of rice husk chars through using random pore model. Biores Technol. 2016;218:1073–81.

Su X, Guo L, Jin H. Mathematical modeling for coal gasification kinetics in supercritical water. Energy Fuels. 2016;30(11):9028–35.

Kestel M, Nikrityuk P, Meyer B, (eds.). Numerical study of partial oxidation of a single coal particle in a stream of air. In: 2010 14th international heat transfer conference; 2010: American Society of Mechanical Engineers.

Safronov D, Kestel M, Nikrityuk P, Meyer B. Particle resolved simulations of carbon oxidation in a laminar flow. Can J Chem Eng. 2014;92(10):1669–86.

Zhao X, Jin H. Investigation of hydrogen diffusion in supercritical water: a molecular dynamics simulation study. Int J Heat Mass Transf. 2019;133:718–28.

Coetzee GH, Sakurovs R, Neomagus HWJP, Morpeth L, Everson RC, Mathews JP, et al. Pore development during gasification of South African inertinite-rich chars evaluated using small angle X-ray scattering. Carbon. 2015;95:250–60. https://doi.org/10.1016/j.carbon.2015.08.030.

Feng B, Bhatia SK. Variation of the pore structure of coal chars during gasification. Carbon. 2003;41(3):507–23.

Sadhukhan AK, Gupta P, Saha RK. Characterization of porous structure of coal char from a single devolatilized coal particle: coal combustion in a fluidized bed. Fuel Process Technol. 2009;90(5):692–700. https://doi.org/10.1016/j.fuproc.2008.12.010.

Jin H, Fan C, Wei W, Zhang D, Sun J, Cao C. Evolution of pore structure and produced gases of Zhundong coal particle during gasification in supercritical water. J Supercrit Fluids. 2018;136:102–9.

Acknowledgements

This work was financially supported by the National Key R&D Program of China (2016YFB0600100) and the National Natural Science Foundation of China (51776169).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, C., Jin, H., Chen, Y. et al. A numerical study on gasification of a single-pore char particle in supercritical water. J Therm Anal Calorim 141, 1591–1603 (2020). https://doi.org/10.1007/s10973-020-09446-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09446-9