Abstract

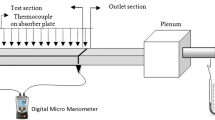

A study was conducted to enhance the thermo-hydraulic performance of a rectangular solar air passage with integrated spherical-shaped turbulence promoters. The effects of the flow and geometric parameters on heat transfer along with the friction factor were studied. The experiments were carried out with a relevant range of the Reynolds number from 4500 to 16,500, and geometric parameters consisting of the dimensionless spherical-shaped diameter \((D_{\text{s}} /D_{\text{H}} )\) from 0.130 to 0.217, the stream-wise spacing parameter \((X_{\text{s}} /D_{\text{s}} )\) from 4.04 to 6.47 and the span-wise spacing parameter \((Y_{\text{s}} /D_{\text{s}} )\) from 4.04 to 6.47. An analysis was further carried out to develop empirical correlations for the Nusselt number and the friction factor in terms of geometric parameters and the Reynolds number. Comparisons between results of correlations and the experimental data revealed good agreements. Results showed that, at a specific Reynolds number, the Nusselt number reached a peak at \(D_{\text{s}} /D_{\text{H}}\) and \(Y_{\text{s}} /D_{\text{s}}\) of 0.195 and 4.62, respectively. An increase in the value of \(D_{\text{s}} /D_{\text{H}}\) increases the friction factor, while an increase in \((X_{\text{s}} /D_{\text{s}} )\) and \(Y_{\text{s}} /D_{\text{s}}\) decreased the friction factor. Maximum friction factor for \(D_{\text{s}} /D_{\text{H}}\), \((X_{\text{s}} /D_{\text{s}} )\) and \(Y_{\text{s}} /D_{\text{s}}\) was found at 0.217, 4.04 and 4.04, respectively. In addition, to evaluate the thermo-hydraulic performance, an efficiency parameter called the efficiency factor was calculated. The maximum value of the efficiency factor was 2.98, which occurred at the Reynolds number of 10,500 corresponding to the optimal parameters \(D_{\text{s}} /D_{\text{H}}\) = 0.195, \(X_{\text{s}} /D_{\text{s}}\) = 4.04, and \(Y_{\text{s}} /D_{\text{s}}\) = 4.62.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.Abbreviations

- \(A_{\text{p}}\) :

-

Surface area of heated plate (m2)

- \(A_{\text{ori}}\) :

-

Area of the orifice (m2)

- \(C_{\text{do}}\) :

-

Discharge Coefficient

- \(c_{\text{p}}\) :

-

Specific heat of air (J kg−1K−1)

- \(D_{\text{H}}\) :

-

Hydraulic diameter (m)

- \(D_{\text{S}}\) :

-

Obstacle diameter (m)

- \({\text{EEC}}\) :

-

Efficiency evaluation criterion

- \(f_{\text{rs}}\) :

-

Friction factor of the plate with obstacles

- \(f_{\text{ss}}\) :

-

Friction factor of the smooth plate

- \(h_{\text{t}}\) :

-

Convective heat transfer coefficient (W m−2 K−1)

- \(H_{\text{P}}\) :

-

Height of the air passage (m)

- \(k_{\text{a}}\) :

-

Air conductivity (W m−1 K−1)

- \(L_{\text{P}}\) :

-

Length of passage (m)

- \(L_{\text{t}}\) :

-

Length of test segment (m)

- \(\dot{m}_{\text{a}}\) :

-

Mass flow rate of air (kg s−1)

- N :

-

Number of sensors

- \(Nu_{\text{rs}}\) :

-

Nusselt number of the plate with obstacles

- \(Nu_{\text{ss}}\) :

-

Nusselt number of the smooth plate

- \((\Delta P)_{\text{d}}\) :

-

Pressure drop across test segment (Pa)

- \((\Delta P)_{\text{o}}\) :

-

Pressure drop across orifice plate (Pa)

- Pr :

-

Prandtl number

- \(\dot{Q}_{\text{u}}\) :

-

Useful energy gain (W)

- \(Re\) :

-

Reynolds number

- \(T_{\text{f}}\) :

-

Mean air temperature (K)

- \(T_{\text{i}}\) :

-

Mean inlet air temperature (K)

- \(T_{\text{p}}\) :

-

Mean plate temperature (K)

- \(T_{\text{o}}\) :

-

Mean outlet air temperature (K)

- \(V\) :

-

Mean air velocity (m s−1)

- \(W_{\text{P}}\) :

-

Width of air passage (m)

- \(\beta_{\text{O}}\) :

-

Ratio of the open area (%)

- \(\beta_{\text{R}}\) :

-

Ratio of the orifice diameter to the pipe diameter

- \(\rho_{\text{a}}\) :

-

Density of air (kg m−3)

- \(\nu_{\text{a}}\) :

-

Kinematic viscosity of air (m2 s−1)

- \(\eta_{\text{p}}\) :

-

Efficiency factor

References

Kumar A, Kim MH. CFD analysis on the thermal hydraulic performance of an SAH duct with multi V-shape roughened ribs. Energies. 2016;9(6):415.

Zhou G, Ye Q. Experimental investigations of thermal and flow characteristics of curved trapezoidal winglet type vortex generators. Appl Therm Eng. 2012;37:241–8.

Park JS, Jo YH, Kwak JS. Heat transfer in a rectangular duct with perforated blockages and dimpled side walls. Int J Heat Mass Transf. 2016;97:224–31.

Sangtarash F, Shokuhmand H. Experimental and numerical investigation of the heat transfer augmentation and pressure drop in simple, dimpled and perforated dimpled louver fin banks with an in-line or staggered arrangement. Appl Therm Eng. 2015;82:194–205.

Bhushan B, Singh R. Nusselt number and friction factor correlations for solar air heater duct having artificially roughened absorber plate. Sol Energy. 2011;85(5):1109–18.

Chang SW, Liou TM, Lee TH. Thermal performance comparison between radially rotating ribbed parallelogram channels with and without dimples. Int J Heat Mass Transf. 2012;55(13):3541–59.

Shen Z, Xie Y, Zhang D. Numerical predictions on fluid flow and heat transfer in U-shaped channel with the combination of ribs, dimples and protrusions under rotational effects. Int J Heat Mass Transf. 2015;80:494–512.

Kumar A, Kim MH. Numerical study on overall thermal performance in SAH duct with compound roughness of V-shaped ribs and dimples. J Korean Sol Energy Soc. 2015;35(4):43–55.

Shui-lian L, Xiang-rui M, Xin-li W. Heat transfer and friction factor correlations for solar air collectors with hemispherical protrusion artificial roughness on the absorber plate. Sol Energy. 2015;118:460–8.

Prasad BN, Saini JS. Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol Energy. 1988;41(6):555–60.

Sahu MM, Bhagoria JL. Augmentation of heat transfer coefficient by using 90 broken transverse ribs on absorber plate of solar air heater. Renew Energy. 2005;30(13):2057–73.

Gupta D, Solanki SC, Saini JS. Thermohydraulic performance of solar air heaters with roughened absorber plates. Sol Energy. 1997;61(1):33–42.

Aharwal KR, Gandhi BK, Saini JS. Experimental investigation on heat-transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew Energy. 2008;33(4):585–96.

Raj AK, Kunal G, Srinivas M, Jayaraj S. Performance analysis of a double-pass solar air heater system with asymmetric channel flow passages. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7762-1.

Kherbeet AS, Mohammed HA, Salman BH, Ahmed HE, Alawi OA, Rashidi MM. Experimental study of nanofluid flow and heat transfer over microscale backward- and forward-facing steps. Exp Therm Fluid Sci. 2015;65:13–21. https://doi.org/10.1016/j.expthermflusci.2015.02.023.

Menasria F, Zedairia M, Moummi A. Numerical study of thermohydraulic performance of solar air heater duct equipped with novel continuous rectangular baffles with high aspect ratio. Energy. 2017;133:593–608.

Singh S, Chander S, Saini JS. Investigations on thermo-hydraulic performance due to flow-attack-angle in V-down rib with gap in a rectangular duct of solar air heater. Appl Energy. 2012;97:907–12.

Karwa R, Bairwa RD, Jain BP, Karwa N. Experimental study of the effects of rib angle and discretization on heat transfer and friction in an asymmetrically heated rectangular duct. J Enhanc Heat Transf. 2005;12(4):343–55.

Ravi RK, Saini RP. Experimental investigation on performance of a double pass artificial roughened solar air heater duct having roughness elements of the combination of discrete multi V shaped and staggered ribs. Energy. 2016;116:507–16.

Bekele A, Mishra M, Dutta S. Performance characteristics of solar air heater with surface mounted obstacles. Energy Convers Manag. 2014;85:603–11.

Saini RP, Verma J. Heat transfer and friction factor correlations for a duct having dimple-shape artificial roughness for solar air heaters. Energy. 2008;33(8):1277–87.

Hossain MS, Pandey AK, Tunio MA, Selvaraj J, Hoque KE, Rahim NA. Thermal and economic analysis of low-cost modified flat-plate solar water heater with parallel two-side serpentine flow. J Therm Anal Calorim. 2016;123(1):793–806.

Chamoli S, Thakur NS. Exergetic performance evaluation of solar air heater having V-down perforated baffles on the absorber plate. J Therm Anal Calorim. 2014;117(2):909–23.

Negi DS, Pattamatta A. Profile shape optimization in multi-jet impingement cooling of dimpled topologies for local heat transfer enhancement. Heat Mass Transf. 2015;51(4):451–64.

Jin D, Zhang M, Wang P, Xu S. Numerical investigation of heat transfer and fluid flow in a solar air heater duct with multi V-shaped ribs on the absorber plate. Energy. 2015;89:178–90.

Handoyo EA, Ichsani D, Prabowo S. Numerical studies on the effect of delta-shaped obstacles’ spacing on the heat transfer and pressure drop in v-corrugated channel of solar air heater. Sol Energy. 2016;131:47–60.

Skullong S, Promvonge P, Thianpong C, Jayranaiwachira N, Pimsarn M. Heat transfer augmentation in a solar air heater channel with combined winglets and wavy grooves on absorber plate. Appl Therm Eng. 2017;122:268–84.

Ravi RK, Saini RP. Nusselt number and friction factor correlations for forced convective type counter flow solar air heater having discrete multi V shaped and staggered rib roughness on both sides of the absorber plate. Appl Therm Eng. 2018;129:735–46.

Abuşka M. Energy and exergy analysis of solar air heater having new design absorber plate with conical surface. Appl Therm Eng. 2018;131:115–24.

Kumar BA, Kumar A, Maithani R, Kumar R, Kumar S, Chauhan R. Experimental study on heat transfer and fluid flow enhancement of a spherical shape obstacle solar air passage. Therm Sci. 2017;23:220.

Manjunath MS, Karanth KV, Sharma NY. Numerical analysis of the influence of spherical turbulence generators on heat transfer enhancement of flat plate solar air heater. Energy. 2017;121:616–30.

Garoosi F, Hoseininejad F, Rashidi MM. Numerical study of natural convection heat transfer in a heat exchanger filled with nanofluids. Energy. 2016;109:664–78.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z. Nanofluid heat transfer and entropy generation through a heat exchanger considering a new turbulator and CuO nanoparticles. J Therm Anal Calorim. 2018;134:2295–303. https://doi.org/10.1007/s10973-018-7866-7.

Jafaryar M, Sheikholeslami M, Li Z, Moradi R. Nanofluid turbulent flow in a pipe under the effect of twisted tape with alternate axis. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7093-2.

Nematpour Keshteli A, Sheikholeslami M. Nanoparticle enhanced PCM applications for intensification of thermal performance in building: a review. J Mol Liq. 2019;274:516–33.

Rashidi MM, Nasiri M, Shadloo MS, Yang Z. Entropy generation in a circular tube heat exchanger using nanofluids: effects of different modeling approaches. Heat Transf Eng. 2016. https://doi.org/10.1080/01457632.2016.1211916.

Garoosi F, Hoseininejad F, Rashidi MM. Numerical study of heat transfer performance of nanofluids in a heat exchanger. Appl Therm Eng. 2016;105:436–55.

Sheikholeslami M, Sajjadi H, Amiri Delouei A, Atashafrooz M, Li Z. Magnetic force and radiation influences on nanofluid transportation through a permeable media considering Al2O3 nanoparticles. J Therm Anal Calorim. 2018;1:1. https://doi.org/10.1007/s10973-018-7901-8.

Sheikholeslami M. Numerical approach for MHD Al2O3–water nanofluid transportation inside a permeable medium using innovative computer method. Comput Methods Appl Mech Eng. 2018. https://doi.org/10.1016/j.cma.2018.09.042.

Sheikholeslami M, Haq R, Shafee A, Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int J Heat Mass Transf. 2019;130:1322–42.

Sheikholeslami M. New computational approach for exergy and entropy analysis of nanofluid under the impact of Lorentz force through a porous media. Comput Methods Appl Mech Eng. 2018. https://doi.org/10.1016/j.cma.2018.09.044.

Sheikholeslamia M, Barzegar Gerdroodbarya M, Moradic R, Shafeed A, Li Z. Application of Neural Network for estimation of heat transfer treatment of Al2O3–H2O nanofluid through a channel. Comput Methods Appl Mech Eng. 2019;344:1–12.

Sheikholeslami M, Mahian O. Enhancement of PCM solidification using inorganic nanoparticles and an external magnetic field with application in energy storage systems. J Clean Prod. 2019;215:963–77.

ASHRAE Standard 93. Method of testing to determine the thermal performance of solar collectors. Atlanta: American Society of Heating, Refrigeration and Air Conditioning Engineers; 2003.

Klein SJ, Mc Clintock A. The description of uncertainties in a single sample experiments. Mech Eng. 1953;75:3–8.

Webb RL, Eckert ERG. Application of rough surfaces to heat exchanger design. Int J Heat Mass Transf. 1972;15(9):1647–58.

Liu W, Liu Z, Ma L. Application of a multi-field synergy principle in the performance evaluation of convective heat transfer enhancement in a tube. Chin Sci Bull. 2012;57(13):1600–7.

Ma L, Yang J, Liu W, Zhang X. Physical quantity synergy analysis and efficiency evaluation criterion of heat transfer enhancement. Int J Therm Sci. 2014;80:23–32.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maithani, R., Kumar, A., Gholamali Zadeh, P. et al. Empirical correlations development for heat transfer and friction factor of a solar rectangular air passage with spherical-shaped turbulence promoters. J Therm Anal Calorim 139, 1195–1212 (2020). https://doi.org/10.1007/s10973-019-08551-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08551-8