Abstract

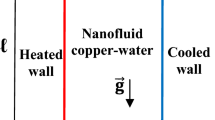

Entropy generation analysis for the Cu–water nanofluid flow through a heat exchanger tube equipped with perforated conical rings is numerically investigated. Frictional and thermal entropy generation rates are defined as functions of velocity and temperature gradients. Governing equations are solved by using finite volume method, and Reynolds number is in the range of 5000–15,000. The effects of geometrical and physical parameters such as Reynolds number, number of holes and nanoparticles volume fraction on the thermal and viscous entropy generation rates and Bejan number are investigated. The results indicate that the thermal irreversibility is dominant in most part of the tube. But it decreases with increasing the nanoparticle volume fraction. Frictional entropy generation reduces with increasing the number of holes from 4 to 10. This is because of stronger velocity gradient near the perforated holes. Bejan number decreases with augment of Reynolds number.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area (m2)

- Be :

-

Bejan number

- C p :

-

Specific heat (J kg−1 K−1)

- d :

-

Hole diameter (m)

- D :

-

Tube diameter (m)

- d p :

-

Nanoparticle diameter (m)

- f :

-

Friction factor

- h :

-

Heat transfer coefficient (Wm−2 K−1)

- k :

-

Thermal conductivity (Wm−1 K−1)

- L :

-

Tube length (m)

- N :

-

Number of perforated holes

- N g :

-

Dimensionless entropy generation

- N t :

-

Total entropy generation

- Nu :

-

Nusselt number

- Pr :

-

Prandtl number

- Re :

-

Reynolds number

- \(S_{\text{g}}^{\prime \prime \prime }\) :

-

Local entropy generation (Wm−3 K−1)

- t :

-

PCR thickness (m)

- T :

-

Temperature (K)

- w :

-

PCR width (m)

- \(\mu\) :

-

Fluid dynamic viscosity (kg m−1 s−1)

- \(\nu\) :

-

Fluid kinematic viscosity (m2 s−1)

- \(\rho\) :

-

Fluid density (kg m−3)

- \(\phi\) :

-

Nanoparticle volume fraction

- eff:

-

Effective

- f:

-

Base fluid

- g:

-

Generation

- in:

-

Inlet

- p:

-

Particle

- t:

-

Turbulent

References

Nouri-Borujerdi A, Nakhchi M. Experimental study of convective heat transfer in the entrance region of an annulus with an external grooved surface. Exp Thermal Fluid Sci. 2018;98:557–62.

Nakhchi M. Experimental optimization of geometrical parameters on heat transfer and pressure drop inside sinusoidal wavy channels. Therm Sci Eng Prog. 2018;9:121–31.

Nouri-Borujerdi A, Nakhchi M. Heat transfer enhancement in annular flow with outer grooved cylinder and rotating inner cylinder: review and experiments. Appl Therm Eng. 2017;120:257–68.

Akbarzadeh M, Rashidi S, Karimi N, Omar N. First and second laws of thermodynamics analysis of nanofluid flow inside a heat exchanger duct with wavy walls and a porous insert. J Therm Anal Calorim. 2018;135:177–94. https://doi.org/10.1007/s10973-018-7044-y.

Nouri-Borujerdi A, Nakhchi M. Prediction of local shear stress and heat transfer between internal rotating cylinder and longitudinal cavities on stationary cylinder with various shapes. Int J Therm Sci. 2019;138:512–20.

Nouri-Borujerdi A, Nakhchi M. Friction factor and Nusselt number in annular flows with smooth and slotted surface. Heat Mass Transf. 2018;55:645–53. https://doi.org/10.1007/s00231-018-2445-9.

Nakhchi M, Esfahani J. Cu–water nanofluid flow and heat transfer in a heat exchanger tube equipped with cross-cut twisted tape. Powder Technol. 2018;339:985–94.

Jafaryar M, Sheikholeslami M, Li Z, Moradi R. Nanofluid turbulent flow in a pipe under the effect of twisted tape with alternate axis. J Therm Anal Calorim. 2018;135:305–23. https://doi.org/10.1007/s10973-018-7093-2.

Nakhchi M, Esfahani J. Numerical investigation of rectangular-cut twisted tape insert on performance improvement of heat exchangers. Int J Therm Sci. 2019;138:75–83.

Promvonge P, Eiamsa-ard S. Heat transfer behaviors in a tube with combined conical-ring and twisted-tape insert. Int Commun Heat Mass Transf. 2007;34:849–59.

Menni Y, Azzi A, Chamkha A. Enhancement of convective heat transfer in smooth air channels with wall-mounted obstacles in the flow path. J Therm Anal Calorim. 2018;135:1951–76. https://doi.org/10.1007/s10973-018-7268-x.

Akbarzadeh M, Rashidi S, Masoodi R, Samimi-Abianeh O. Effect of transverse twisted baffles on performance and irreversibilities in a duct. J Thermophys Heat Transf. 2018;33:49–62. https://doi.org/10.2514/1.T5373.

Zade NM, Akar S, Rashidi S, Esfahani JA. Thermo-hydraulic analysis for a novel eccentric helical screw tape insert in a three dimensional tube. Appl Therm Eng. 2017;124:413–21.

Messoul A, Laribi B, Youcefi A, Kolsi L, Abdelkarim A, Aichouni M. Numerical investigation of the performance of the etoile flow conditioner under different geometric and dynamic configurations. J Eur Syst Autom. 2018;51:141.

Aichouni M, Kolsi L, Ait-Messaoudenne N, Aich W. Computational study of the performance of the Etoile flow conditioner. Int J Adv Appl Sci. 2016;3:25–30.

Elashmawy M, Kolsi L. Turbulent forced convection heat transfer in triangular cross sectioned helically coiled tube. Int J Adv Appl Sci. 2016;3:18–23.

Nouri-Borujerdi A, Nakhchi M. Optimization of the heat transfer coefficient and pressure drop of Taylor–Couette–Poiseuille flows between an inner rotating cylinder and an outer grooved stationary cylinder. Int J Heat Mass Transf. 2017;108:1449–59.

Bejan A. Entropy generation minimization: the method of thermodynamic optimization of finite-size systems and finite-time processes. Boca Raton: CRC Press; 2013.

Chamkha A, Rashad A, Armaghani T, Mansour M. Effects of partial slip on entropy generation and MHD combined convection in a lid-driven porous enclosure saturated with a Cu–water nanofluid. J Therm Anal Calorim. 2018;132:1291–306.

Mohseni-Gharyehsafa B, Ebrahimi-Moghadam A, Okati V, Farzaneh-Gord M, Ahmadi MH, Lorenzini G. Optimizing flow properties of the different nanofluids inside a circular tube by using entropy generation minimization approach. J Therm Anal Calorim. 2018;135:801–11. https://doi.org/10.1007/s10973-018-7276-x.

Javadi P, Rashidi S, Esfahani JA. Effects of rib shapes on the entropy generation in a ribbed duct. J Thermophys Heat Transf. 2017;32:691–701. https://doi.org/10.2514/1.T5298.

Mehta SK, Pati S. Analysis of thermo-hydraulic performance and entropy generation characteristics for laminar flow through triangular corrugated channel. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7969-1.

Shamsabadi H, Rashidi S, Esfahani JA. Entropy generation analysis for nanofluid flow inside a duct equipped with porous baffles. J Therm Anal Calorim. 2018;135:1009–19. https://doi.org/10.1007/s10973-018-7350-4.

Rashidi S, Zade NM, Esfahani JA. Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape insert in a 3D tube. Chem Eng Process. 2017;117:27–37.

Shahriari A, Ashorynejad HR, Pop I. Entropy generation of MHD nanofluid inside an inclined wavy cavity by lattice Boltzmann method. J Therm Anal Calorim. 2018;135:283–303. https://doi.org/10.1007/s10973-018-7061-x.

Yakut K, Sahin B. Flow-induced vibration analysis of conical rings used for heat transfer enhancement in heat exchangers. Appl Energy. 2004;78:273–88.

Promvonge P, Eiamsa-Ard S. Heat transfer enhancement in a tube with combined conical-nozzle inserts and swirl generator. Energy Convers Manag. 2006;47:2867–82.

Promvonge P. Heat transfer behaviors in round tube with conical ring inserts. Energy Convers Manag. 2008;49:8–15.

Kongkaitpaiboon V, Nanan K, Eiamsa-Ard S. Experimental investigation of heat transfer and turbulent flow friction in a tube fitted with perforated conical-rings. Int Commun Heat Mass Transf. 2010;37:560–7.

Chamoli S, Lu R, Yu P. Thermal characteristic of a turbulent flow through a circular tube fitted with perforated vortex generator inserts. Appl Therm Eng. 2017;121:1117–34.

Mashayekhi R, Khodabandeh E, Bahiraei M, Bahrami L, Toghraie D, Akbari OA. Application of a novel conical strip insert to improve the efficacy of water–Ag nanofluid for utilization in thermal systems: a two-phase simulation. Energy Convers Manag. 2017;151:573–86.

Esfe MH, Saedodin S. Turbulent forced convection heat transfer and thermophysical properties of Mgo–water nanofluid with consideration of different nanoparticles diameter, an empirical study. J Therm Anal Calorim. 2015;119:1205–13.

Estellé P, Mahian O, Maré T, Öztop HF. Natural convection of CNT water-based nanofluids in a differentially heated square cavity. J Therm Anal Calorim. 2017;128:1765–70.

Toghraie D, Abdollah MMD, Pourfattah F, Akbari OA, Ruhani B. Numerical investigation of flow and heat transfer characteristics in smooth, sinusoidal and zigzag-shaped microchannel with and without nanofluid. J Therm Anal Calorim. 2018;131:1757–66.

Arabpour A, Karimipour A, Toghraie D, Akbari OA. Investigation into the effects of slip boundary condition on nanofluid flow in a double-layer microchannel. J Therm Anal Calorim. 2018;131:2975–91.

Rashidi S, Karimi N, Mahian O, Esfahani JA. A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calorim. 2018;135:1145–1159. https://doi.org/10.1007/s10973-018-7500-8.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Siavashi M, Taylor RA, Niazmand H. Recent advances in modeling and simulation of nanofluid flows-part I: fundamental and theory. Phys Rep. 2018;790:1–48.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Taylor RA, Abu-Nada E, Rashidi S. Recent advances in modeling and simulation of nanofluid flows-part II: applications. Phys Rep. 2018;791:1–59.

Rashidi S, Akbarzadeh M, Karimi N, Masoodi R. Combined effects of nanofluid and transverse twisted-baffles on the flow structures, heat transfer and irreversibilities inside a square duct—a numerical study. Appl Therm Eng. 2018;130:135–48.

Laein RP, Rashidi S, Esfahani JA. Experimental investigation of nanofluid free convection over the vertical and horizontal flat plates with uniform heat flux by PIV. Adv Powder Technol. 2016;27:312–22.

Shirejini SZ, Rashidi S, Esfahani JA. Recovery of drop in heat transfer rate for a rotating system by nanofluids. J Mol Liq. 2016;220:961–9.

Rashidi S, Bovand M, Esfahani JA. Opposition of Magnetohydrodynamic and AL2O3–water nanofluid flow around a vertex facing triangular obstacle. J Mol Liq. 2016;215:276–84.

Bovand M, Rashidi S, Esfahani JA. Optimum interaction between magnetohydrodynamics and nanofluid for thermal and drag management. J Thermophys Heat Transf. 2016;31:218–29.

Sundar LS, Sharma K. Turbulent heat transfer and friction factor of Al2O3 nanofluid in circular tube with twisted tape inserts. Int J Heat Mass Transf. 2010;53:1409–16.

Santra AK, Sen S, Chakraborty N. Study of heat transfer due to laminar flow of copper–water nanofluid through two isothermally heated parallel plates. Int J Therm Sci. 2009;48:391–400.

Saysroy A, Eiamsa-ard S. Enhancing convective heat transfer in laminar and turbulent flow regions using multi-channel twisted tape inserts. Int J Therm Sci. 2017;121:55–74.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52:789–93.

Rashidi S, Akbarzadeh M, Masoodi R, Languri E. Thermal-hydraulic and entropy generation analysis for turbulent flow inside a corrugated channel. Int J Heat Mass Transf. 2017;109:812–23.

Bashi M, Rashidi S, Esfahani JA. Exergy analysis for a plate-fin triangular duct enhanced by a porous material. Appl Therm Eng. 2017;110:1448–61.

Acknowledgements

This research was supported by the Office of the Vice Chancellor for Research, Ferdowsi University of Mashhad, under Grant No. 48255.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nakhchi, M.E., Esfahani, J.A. Entropy generation of turbulent Cu–water nanofluid flow in a heat exchanger tube fitted with perforated conical rings. J Therm Anal Calorim 138, 1423–1436 (2019). https://doi.org/10.1007/s10973-019-08169-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08169-w