Abstract

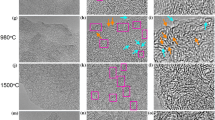

A new ceramic material “Vikaflex®” was developed from industrially pyrolized shale solid residue. Thermal properties of this material were studied by thermal microscopy, TG, DTG and DTA analyses at temperature from 400 to 1,400 °C. The thermal expansion coefficient was estimated from the heating microscope images for the solid phase before losing its shape using an improvement of a previous method. The specific heat capacity and mass change between 600 and 1,100 °C were detected. This porous solid material shows high thermal stability up to 1,050 °C.

Similar content being viewed by others

References

Raupp-Pereira F, Hotza D, Segadães AM, Labrincha JA. Ceramic formulations prepared with industrial wastes and natural sub-products. Ceram Intern. 2006;32:173–9.

Fonseca MVA. Vikaflex: um novo material cerâmico leve para a construção civil in Xisto—Pesquisas, Revisões e Ensaios Realizados no Brasil, Ed CRV. 2014:135–60.

Fonseca MVA. Reciclagem de rejeitos sólidos; desenvolvimento, em escala de laboratório, de materiais vítreos a partir do xisto retortado de S Mateus Sul, PR. Doc dissert, USP, SP, Br. 1990.

Q X, Li X, Li W, Zhou H, Xu S. Attapulgite-shale river bottom sludge ceramic particle sintered porous construction block, Faming Zhuanli Shenqing, CN 102924056 A 20130213. 2013.

Jin Y, Chen D. Oil shale residue aerated brick and manufacture method, Faming Zhuanli Shenqing, CN 102875184 A 20130116. 2013.

Weng L, Shale composite sintered brick for walling and its manufacture, Faming Zhuanli Shenqing, CN 101353250 A 20090128. 2009.

Colak M, Ozkan I. Sintering properties of the Bornova shale (Turkey) and its application in the production of red fired ceramics. Ind Ceram. 2011;31(3):209–15.

Shil’tsina AD, Selivanov VM. Non-plastic raw material for production of construction ceramics in Khakassia. Izvestiya Vysshikh Uchebnykh Zavedenii, Stroitel’stvo. 1998;2:53–6.

Hou Z, Mao X, Liu D. Method for manufacturing foamed ceramic heat-insulating plate from shale and clinker, Faming Zhuanli Shenqing, CN 103011786 A 20130403. 2013.

Jin J, Jin J. Method for preparation of high-performance ultra-lightweight foam ceramics with shale as main raw material, Faming Zhuanli Shenqing, CN 102603347 A 20120725. 2012.

Feng Z, Xue X, Li Y, Yang H. Preparation of foam glass-ceramic from oil shale residue. Guocheng Gongcheng Xuebao. 2008;8(2):378–83.

Li Y, Liu C. Foam glass prepared from shale, and its preparation method, Faming Zhuanli Shenqing, CN 103570245 A 20140212. 2014.

Takada T, Sarai H, Takahashi T, Miyazaki Y. Manufacture of bubble glass from shale, Jpn. Kokai Tokkyo Koho, JP 01141839 A 19890602. 1989.

Jin J, Jin J. Ultra-light vitreous foam ceramic and preparation method thereof by crushing, pelleting, screening, molding sintering and cutting, Faming Zhuanli Shenqing, CN 103922791 A 20140716. 2014.

Yang J, Chen J, Tang X, Qu X, Zhang P, Fan X, Xu L, Meng L, Tang Y, LVQ et al. Method for production of heat- and sound-insulating board, Faming Zhuanli Shenqing, CN 103803897 A 20140521. 2014.

Lu S, Yang L. Suspended shale ceramsite filtering material for water treatment and fabrication method, Faming Zhuanli Shenqing, CN 103304241 A 20130918. 2013.

Wang L. Wallboard and its manufacture method by resource utilization of municipal solid wastes, Faming Zhuanli Shenqing, CN 101239811 A 20080813. 2008.

Wu J, Zhu F, Xu X, Zeng Q, Chen J, Teng F. Method for production of environment-friendly water-permeable ceramic bricks, Faming Zhuanli Shenqing, CN 101328044 A 20081224. 2008.

Soares W, Menezes VJ, Fonseca MVA, Dweck J. Characterization of carbonaceous products by TG and DTA. J Therm Anal Calorim. 1997;49:657–61.

Perruso CR, Alcover Neto A, Neumann R, Nascimento RSV, Fonseca MVA. Powdered microporous glasses: changing porosity through aging. Cer Assoc Bras Ceram. 1998;44:289.

Getrouw MA, Fonseca MVA, Dutra AJB. Process for treatment of red mud for recovery of iron and aluminum hydroxides and production of glass ceramics, Brazil Pedido PI, BR 9602530 A 19981027. 1998.

Perruso CR, Alcover Neto A, Neumann R, Nunes RCR, Fonseca MVA, Nascimento RSV. Oil shale solid waste recycling in the development of new silica fillers for elastomeric composites. J Appl Polym Sci. 2001;81(12):56–2867.

Fonseca MVA. Process for fabrication of low-density ceramic product—lightweight board, Brazil Pedido PI, BR 2009002611 A2 20110412. 2011.

Dweck J, Morais LC, Fonseca MVA, Campos V, Büchler PM. Calcined sludge sintering evaluation by heating microscopy thermal analysis. J Therm Anal Calorim. 2009;95(3):985–9.

Aumond JJ, Scheibe LF. O fonolito de Lajes—SC, um novo fundente cerâmico brasileiro. Ceram Ind. 1996;1(2):17–21.

Arancibia JRH, Alfonso P, García-Valles M, Martínez S, Parcerisa D, Canet C, Romero YFM. Obtención de vidrio a partir de residuos de la minería del estaño en Bolivia. Bol Soc Esp de Cerám y Vidrio. 2013;52(3):143–50.

Venturelli C. Characterization of ceramic bodies through optical techniques: state of tension and green mechanical properties, suranaree. J Sci Technol. 2013;20(1):11–20.

Karamanov A, Dzhantov B, Paganelli M, Sighinolfi D. Glass transition temperature and activation energy of sintering by optical dilatometry. Thermoch Acta. 2013;553:1–7.

Sighinolfi D. Estudo experimental das deformações e estado de tensão em materiais cerâmicos tradicionais. Cerâm Ind. 2011;16(5–6):19–24.

Paganelli M, Venturelli C. The measurement of behaviour of ceramic materials during heat treatment. Process Eng. 2009;6:37–40.

DIN 51730:2007-09. Testing of solid fuels—determination of fusibility of fuel ash. http://www.beuth.de/en/standard/din-51730/98893895 (2014). Accessed 10 sept 2014.

Beveridge P, Doménech I, Pascual E, O Vidro—Técnicas de trabalho de forno; Ed Estampa, Lda, Lisboa. 2004.

Expert Solutions Advanced Thermal Analyses. Deformation temperature. http://www.expertsystemsolutions.com/search-and-documentation/glossary/d/deformation-temperature (2014) Accessed 15 Dec 2014.

Expert Solutions Advanced Thermal Analyses, Softening temperature. http://www.expertsystemsolutions.com/search-and-documentation/glossary/s/softening-temperature (2014). Accessed 15 Dec 2014.

Expert Solutions Advanced Thermal Analyses, Sphere temperature. http://www.expertsystemsolutions.com/search-and-documentation/glossary/h/hemisphere-temperature (2014). Accessed 15 Dec 2014.

Expert Solutions Advanced Thermal Analyses, Hemisphere temperature. http://www.expertsystemsolutions.com/search-and-documentation/glossary/h/hemisphere-temperature (2014). Accessed 15 Dec 2014.

Expert Solutions Advanced Thermal Analyses, Flow (Melting) temperature. http://www.expertsystemsolutions.com/search-and-documentation/glossary/f/flattening-melting-behaviour. Accessed 15 Dec 2014.

Callister WD. Fundamentals of materials science and engineering, an interactive E/text. 5th ed. NY, USA: Wiley; 2001.

Bagatini MC, Ghiggi MLF, Osório E, Vilela ACF, Cruz R, Defendi G. Estudo da fusibilidade das cinzas de carvões em função da composição química e mineralógica. Tec Metal e Mat. 2007;3(4):52–8.

Sousa JJF, Diehl LMA, Vugman NV, Fonseca MVA, Costa Neto C. Electron paramagnetic resonance and Moessbauer spectrometry of spent oil shale undergoing thermal treatment. An Acad Brasi Ciên. 1994;66(1):13–22.

Marchal G. Recherches sur la decomposition des sulfates metalliques par la chaleur. J Chem Phisiq. 1926;23:38–60.

Acknowledgements

The authors would like to thank Centro de Tecnologia Mineral (CETEM), and in particular Dr. Reiner Newman, for assistance in the chemical analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rangel, B.F., Viana, M.M., Fonseca, M.V.A. et al. Thermal characterization of a new green ceramic material by heating microscopy, thermogravimetry and differential thermal analysis. J Therm Anal Calorim 121, 115–125 (2015). https://doi.org/10.1007/s10973-015-4496-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4496-1