Abstract

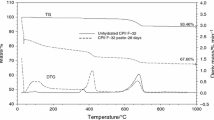

The pozzolanic properties of the equilibrium catalyst (Ecat), an abundant waste from fluid catalytic cracking units of oil refineries, have been studied in cementitious matrices. The consumption of calcium hydroxide is usually taken as a means to assess the pozzolanicity of a material, ignoring the formation of C–S–H and other hydrates, the main product of the pozzolanic reaction. The use of thermal analysis methods allows the identification and quantification of the products of the hydration reaction, based on the loss of chemically combined water of phases present in a cementitious matrix. In the present study, TG/DTG techniques were used to quantify the amount of C–S–H + ettringite, C–A–S–H + C–A–H, and calcium hydroxide in cement–Ecat pastes, containing 0–40 % Ecat, aged for 1–28 days. The influence of the content of these phases on the mechanical properties of the resulting samples was also investigated by axial compression. The results further confirmed the pozzolanic activity of Ecat, so that the production of C–S–H and C–A–S–H increased with the aging time, but in a smaller amount than in the reference paste. The compressive strength test showed that the pastes containing 10 % Ecat, aged for 14 and 28 days, presented improved properties as compared to the corresponding references.

Similar content being viewed by others

References

Tobón JI, Payá J, Borrachero MV, Soriano L, Restrepo OJ. Determination of the optimum parameters in the high resolution thermogravimetric analysis (HRTG) for cementitious materials. J Therm Anal Calorim. 2013;107(1):233–9.

Wongkeo W, Thongsanitgarn P, Chindaprasirt P, Chaipanich A. Thermogravimetry of ternary cement blends: effect of different curing methods. J Therm Anal Calorim. 2013;113(3):1079–90.

Galan I, Andrade C, Castellote M. Thermogravimetrical analysis for monitoring carbonation of cementitious materials. J Therm Anal Calorim. 2012;110(1):309–19.

Melchert MBM, Viana MM, Lemos MS, Dweck J, Buchler PM. Simultaneous solidification of two catalyst wastes and their effect on the early stages of cement hydration. J Therm Anal Calorim. 2011;105(2):625–33.

Mendoza O, Tobón JI. An alternative thermal method for identification of pozzolanic activity in Ca(OH)2/pozzolan pastes. J Therm Anal Calorim. 2013;114(2):589–96.

DE Macphee, Lachowski EE. Cement components and their phase relations. In: Hewllet PC, editor. Lea’s chemistry of cement and concrete. London: Arnold; 1988. p. 95–130.

Taylor HFW. Cement Chemistry. 2nd ed. London: Thomas Telford Publishing; 1997.

Van Odler I. Hydration, setting and hardening of Portland cement. In: Hewllet PC, editor. Lea’s chemistry of cement and concrete. London: Arnold; 1988. p. 241–98.

Guénotq-Delahaie I. Contribuition à l’analyse physique et à la modélisation du fluage propre du béton. These de doctorat de I’Ecole Nationale des Pontset Chaussées, Paris; 1996.

Dweck J, Melchert MBM, Viana MM, Cartledge FK, Büchler PM. Importance of quantitative thermogravimetry on initial cement mass basis to evaluate the hydration of cement pastes and mortars. J Therm Anal Calorim. 2013;113(3):1481–90.

Antonovic V, Aleknevicius M, Kerien J, Pundien I, Stonys R. Investigating the hydration of deflocculated calcium aluminate cement-based binder with catalyst waste. J Therm Anal Calorim. 2012;109(2):537–44.

Cunha ALC, Lemos ML, Meth S, Gonçalves JP, Dweck J. A study of the particle size effect on the pozzolanic activity of an equilibrium catalyst. J Therm Anal Calorim. 2011;106(3):805–9.

Dweck J, Pinto CA, Büchler PM. Study of a Brazilian spent catalyst as cement aggregate by thermal and mechanical analysis. J Therm Anal Calorim. 2008;92:121–7.

Dweck J, Cunha ALC, Pinto CA, Gonçalves JP, Büchler PM. Thermogravimetry on calcined mass basis—hydrated cement phases and pozzolanic activity quantitative analysis. J Therm Anal Calorim. 2009;97(1):85–9.

Cunha ALC, Gonçalves JP, Büchler PM, Dweck J. Effect of metakaolin pozzolanic activity in the early stages of cement type ii paste and mortar hydration. J Therm Anal Calorim. 2008;92(1):115–9.

Pinto CA, Büchler PM, Dweck J. Pozzolanic properties of a residual fcc catalyst during the early stages of cement hydration—evaluation by thermal analysis. J Therm Anal Calorim. 2007;87(3):715–20.

Pacewska B, Wilinska I, Bukowska M, Blonkowski G, Nocún-wczelik W. An attempt to improve the pozzolanic activity of waste aluminosilicate catalyst. J Therm Anal Calorim. 2004;77:133–42.

Payá J, Monzó J, Borrachero MV, Velázquez S. Chemical activation of pozzolanic reaction of fluid catalytic cracking catalyst residue (FC3R) in lime pastes: thermal analysis. Adv Cem Res. 2004;16(3):123–30.

Payá J, Borrachero MV, Monzó J, Soriano L. Studies on the behaviour of different spent fluidized-bed catalytic cracking catalysts on Portland cement. Mater Constr. 2009;59(296):37–52.

Pacewska B, Wilińska I, Kubissa J. Use of spent catalyst from catalytic cracking in fluidized bed as a new concrete additive. Thermochim Acta. 1998;322(2):175–81.

Pacewska B, Wilinska I, Bukowska M. Hydration of cement slurry in the presence of spent cracking catalyst. J Therm Anal Calorim. 2000;60:71–8.

Payá J, Monzó J, Borrachero MV, Velázquez S. Evaluation of the pozzolanic activity of fluid catalytic cracking catalyst residue (FC3R). Thermogravimetric analysis studies on PC3R-Portland cement pastes. Cem Concr Res. 2003;33(4):603–9.

Payá J, Monzó JM, Borrachero MV, Velázquez S. Pozzolanic reaction rate of fluid catalytic cracking catalyst residue (FC3R) in cement pastes. Adv Cem Res. 2013;25(2):112–8.

Lin KL, Wu HH, Chao SJ, Cheng A, Hwang CL. Characteristics of waste catalyst reused as latent hydraulic materials. Environ Prog Sustain Energy. 2013;32(1):94–8.

Brazilian Association of Technical Standards. High early strength Portland cement—specification. Rio de Janeiro: NBR5733; 1991 (in Portuguese).

Brazilian Association of Technical Standards. Compression test of cylindric specimens. Rio de Janeiro: NBR 5739; 2007 (in Portuguese).

Zornoza E, Garcés P, Monzó J, Borrachero MV, Payá J. Accelerated carbonation of cement pastes partially substituted with fluid catalytic cracking catalyst residue (FC3R). Cem Concr Compos. 2009;31(2):134–8.

Acknowledgements

The authors are grateful to CAPES, CNPq, and FAPESB for the scholarships and financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silva, F.G.S., Fiuza Junior, R.A., da Silva, J.S. et al. Consumption of calcium hydroxide and formation of C–S–H in cement pastes. J Therm Anal Calorim 116, 287–293 (2014). https://doi.org/10.1007/s10973-013-3546-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3546-9