Abstract

The adsorbed amounts of water vapor onto polyacrylic polymer (polymer ×10) were measured using a thermogravimetry method as a function of pressure at 298 and 313 K. The adsorption isotherms are categorized to type II isotherms by IUPAC classification leading to a hysteresis loop between adsorption and desorption branches. The current study was completed by the measurement of the adsorption heats at 298 K using a differential scanning calorimetry. The calorimetric curves showed two adsorption heats domains. These domains have been attributed to the adsorption of “equivalent monolayer” and the condensation of water between polymeric chains. The correlation of experimental data to some chosen theoretical models shows that the GAB model is the most adequate to describe water vapor sorption isotherms.

Similar content being viewed by others

Introduction

Several theoretical and experimental studies examined water vapor sorption on different solid surfaces [1–4]. Indeed, the choice of adsorbent solid depends on adsorption capacity, adsorption kinetic, thermal stability, and the amount of thermal energy required for regeneration. In comparison with classical adsorbent like activated carbons [5] and silica gel [6], hydrophilic polymers proved an excellent adsorption capacity. A thermodynamic study of water vapor adsorption onto poly (styrensulfonic acid), sodium salt has indicated that the adsorption capacity of the monosulfonated sample reached more than 80% mass under 80% relative humidity equilibrium and the heat of adsorption was about standard liquefaction enthalpy [7]. Investigation of kinetic and thermodynamics of water vapor adsorption by a polyacrylic polymer has shown that this kind of polymers are characterized by multilayer adsorption followed by a capillary condensation between polymeric chains [8–10]. Erdogan et al. [11] studied the chloroform vapor sorption in polymeric film formed from anthracene labelled linear poly (methyl methacrylate) by surface plasmon resonance spectroscopy. They observed a swelling behavior of polymeric film during adsorption which was explained by capturing chloroform molecules. Adsorption behavior of some organic compounds by polymeric adsorbent was also investigated by several articles because of their favorable physicochemical stability, large adsorption capacity, good selectivity, and structural diversity [12–15]. Knowledge of protein adsorption onto polymer’s surface became a key issue in the development of biomaterials for tissue engineering [16, 17]. Indeed, the hydrophilic polymers showed their efficiency as air dehumidifier [18]. An understanding of the process of adsorption of water vapor on solid surfaces requires knowledge of both the adsorbed amounts and the adsorption heats. The heats of adsorption allow an assessment of the adsorbate–adsorbent interactions [19]. They can also permit distinction between the amounts adsorbed into the outer surface and that fixed between macromolecular chains. Analysis of adsorption isotherms by different mathematical models were also developed by many authors. Among the models most commonly used the theory of Brunauer-Emmet and Teller (BET) [20, 21] the model of the Guggenheim-Anderson and de Boer (GAB) [22, 23] and that of Frenkel [7] Halsey [24] and Hill [25] (FHH).

The ultimate goal of this study was to collect experimental data necessary to elucidate the water vapor adsorption mechanism on polyacrylic polymer. Indeed, the aims of this article were to (i) determine the water vapor adsorption isotherms onto the studied polymer (ii) measure the adsorption heats during the loading of the polymer surface by water vapor (iii) model experimental adsorption isotherms using some selected equations in order to define the more adequate model to describe the obtained results (iv) test the adsorption–desorption reproducibility.

Materials and methods

Material

The polymer is a polyacrylic superabsorbent manufactured under reference NORSOLOR CAS: 903379-8 [26]. The studied polymer presents a surface area of about 2.1 m2/g [27].

Experimental

The adsorption isotherms were carried out by thermogravimetry by means of Mc Bain thermobalance as follows: first, a sample mass of about 10 ± 0.01 mg was treated in situ under a dynamic vacuum at 313 K for 12 h, which defines the reference anhydrous state for adsorption process. Then, the sample temperature was regulated to desired adsorption temperature by maintaining dynamic vacuum. Once the thermal equilibrium was reached, the adsorption branch was drawn up step by step by introducing water vapor into the thermobalance. Desorption branch was performed from a saturated sample by decreasing the water vapor pressure. The equilibrium state was characterized by a plateau of sample mass. The investigated relative pressure range was from 0.04 to 0.08 to prevent water condensation on the walls of the thermobalance. Adsorption–desorption reproducibility was also examined by performing three cycles adsorption–desorption at each studied temperature.

The adsorption heats were measured using a C80 Setaram differential flow calorimeter coupled with manometer [7]. This experimental device allows at the same time the measurement of the water vapor adsorbed amounts and the heat produced by adsorption. The reference state to measure the adsorption heats were obtained by evacuating the sample in situ at 363 K under a dynamic vacuum. The sample mass was about 500 ± 0.01 mg and the adsorption enthalpies were measured at 298 K. The amounts of adsorbed water were calculated from a mass of balance between an equilibrium state and the state before adsorption. In the following text the amount of adsorbed water vapor on the polymer, designated as m a, is expressed as percentage of dried sample mass (mass/%).

Results and discussion

Water vapor adsorption–desorption isotherm

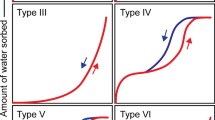

The water vapor adsorption–desorption isotherms measured at 298 and 313 K are shown in Fig. 1. Their shape is categorized to type II isotherm by IUPAC classification [28]. The adsorption and desorption branches are not similar to each other leading to a hysteresis loop, whose magnitude varies with the pressure, as shown in Fig. 1.

However, desorption isotherm shifts upward in the low pressure region. This indicates that the first adsorbed water molecules are strongly bound to the polymeric matrix. The adsorption branches show an inflection point (point B) less identifiable in comparison with the desorption branches. Water vapor adsorption isotherms are characterized by three domains. At low pressure P ≤ 5 mbar denotes the first domain, the amount of adsorbed water during adsorption does not exceed 8 and 10 mass% at 313 and 298 K, respectively, during desorption process, the adsorbed water vapor amount for the same thermodynamics conditions is about 15 and 20 mass%. The second domain, located at pressure values 5 ≤ P ≤ 15 mbar at 298 K and 5 ≤ P ≤ 35 mbar at 313 K, denotes a weak increase of the amount of water adsorbed versus pressure. At high pressure values, the amount of adsorbed water increases sharply from 25 to 60 mass%. Figure 1 shows that the adsorption capacity decreases with increasing the temperature. In fact, since the adsorption process is exothermic, it is favored by low temperatures. During adsorption–desorption process, the observed loop of hysteresis may be related to the state of adsorbed water and the nature of polymeric matrix reflecting their potential for structural and conformational rearrangements [29]. The swelling behavior of polymeric network can also lead to the hysteresis loop. Thus the hysteresis of materials may swell due to the fact that their deformations during swelling and dehydration are not held in flexible manner [30]. In fact, even reducing or eliminating the deformation forces in action, the state of deformation of these materials remains partial. This allows a reduced tension, a reduced swelling pressure and a greater sorption capacity during desorption. In severe or total dehydration irreversible structural changes can occur.

Water vapor adsorption enthalpies

The water vapor adsorption heats were measured from calorimetric experiments at 298 K. The adsorption enthalpies are negative, which confirms that the adsorption process is exothermic. Calorimetric adsorption enthalpies versus the adsorbed amount of water vapor are plotted in Fig. 2.

The calorimetric curve indicates two domains. The first one denotes constant enthalpies values of about 1220 kJ/g (about 67 kJ/mol). In the second domain, the absolute value of adsorption heats decrease with increasing the polymeric solid loading by water vapor until it reaches a similar value to standard liquefaction enthalpy (44 kJ/mol). This result can indicate that at this step, the water vapor adsorption by acrylic polymer is analogous to a condensation of water between the macromolecular chains, and the state of the adsorbate water is similar to liquid state.

Water vapor adsorption mechanism

A thermodynamic investigation of adsorption of gas on polymeric adsorbents is of great significance for developing new adsorbents and elucidating their adsorption behavior. Adsorption isotherm and adsorption enthalpies are basic aspects to clarify the adsorption mechanism.

Adsorption isotherms of water vapor on the acrylic polymer are of type II. This type of isotherm indicates the adsorption of gas onto a surface of nonporous or macroporous solids which present a large surface accessible to outer molecules. The process of adsorption occurs as follows: the solid surface is initially covered by molecular monolayer then a multilayer adsorption process take place [28]. The specific surface area of acrylic polymer is about 2.1 m2/g. Such value is very weak in comparison with those developing by inorganic polymers which also have type II isotherms. In fact, hydrophilic polymers are formed by an entanglement of numerous nonporous macromolecular chains. Thus, the water vapor adsorption mechanism may be different of that of inorganic polymers. Comparing our result with those of Torribio et al. [7] who studied water vapor adsorption onto two poly (styrensulfonic acid), the water vapor adsorption mechanism can occur at two steps. First, water molecules are adsorbed onto the outer surface of polymeric grains and then diffuse between the polymeric chains. The adsorbed water molecules interact with specific adsorption site, and a swelling behavior take place because of the insertion of adsorbed molecules between chains. The amount of water adsorbed on the specific sites of adsorption “bounded water” demotes the first part of the adsorption isotherm until inflection point B. Point B is localized at about 5 mbar and correspond to an adsorption capacity of about 18 mass% at 298 K and 13 mass% at 313 K during desorption. Given that the studied polymer presents a weak specific area, the amount of bounded water adsorbed can be assimilated as “equivalent monolayer”. Beyond point B, the adsorption process occurs following a condensation process. This result is confirmed by calorimetric measurements. The adsorption heat decreases with increasing the polymer loading by water vapor until it reaches a value equal to the standard liquefaction enthalpy as shown in Fig. 2. At high value of water activity, the adsorbed water can dissolve solutes present in the polymeric matrix (sodium in our case) which can induce the increase of the surface tension. The swelling behavior of polymer is more significant at this step and the adsorption process is replaced by an absorption process. At this stage, the adsorbed water is called “free water”.

Functionalized polymers can adsorb through surface force field such as van der Waals force, hydrogen bonding, hydrophobic interaction, and static electrical forces (including ionic bond, covalent bond, and coordinate bond). In our case, we anticipate that ionic bonds, covalent and coordinate bonds can not arise between studied polymer and water vapor. Indeed, water molecules are polar and hydrogen bonding donors as well as hydrogen bonding acceptors can form multiple bonding with hydrogen bonding polymeric functional groups. The measured water vapor adsorption heats ranging from −1220 to −809 kJ/g (−67 to −44 kJ/mol), such values are slightly greater than the hydrogen bonding energies which range between 8 and 50 kJ/mol [17]. Thus, we suggest that adsorption process occurs by involving multiple hydrogen bounds between the water vapor molecules and those of the adsorbent.

Adsorption–desorption isotherm reproducibility

The reproducibility of adsorption–desorption isotherm was also studied. In fact, at each temperature three cycles adsorption–desorption were carried out as shown in Figs. 3 and 4.

Reproducibility of adsorption–desorption process at 298 K (filled circles, filled squares, and filled diamonds: adsorption; open circles, open squares, and open diamonds: desorption). The first, second, and third measurements are expressed by filled diamonds; open diamonds, filled squares; open squares, and filled circles; open circles

Reproducibility of adsorption–desorption process at 313 K (filled circles, filled triangles, and filled diamonds: adsorption; open circles, open triangles, and open diamonds: desorption). The first, second, and third measurements are expressed by filled diamonds; open diamonds, filled triangles; open triangles, and filled circles; open circles)

The shape of the obtained isotherms is almost categorized to type II isotherms. They show an evident hysteresis loop whose magnitude of surface area decreases and stabilizes from the second cycle. In fact, desorption branch is almost reproducible during several adsorption–desorption cycles. The adsorbed amounts during adsorption shifts upward between the first cycle and the subsequent ones. This result can be due to the rearrangement and structural conformations undergone by the polymeric network during the first adsorption process. These structural modifications became stable and the material adopts a steady form during the following cycles.

Modeling of water vapor adsorption–desorption isotherms

Various mathematical models have been proposed in the literature to describe mono or multilayer gas adsorption on solids. Some were developed with theoretical basis to describe adsorption mechanism, whereas others are just empirical or a simplification of more elaborate models.

The most commonly used models to describe the sorption isotherms are the BET theory developed by Brunauer et al. [20] Nonetheless the BET equations have a number of shortcomings, which in due time prompted the proposals of better equations. Among these equations, the GAB equation, and the FHH equation.

The mathematical paradigm of BET equation is:

where P s is the saturated vapor pressure at isotherm temperature, m aBET is the adsorbed amount of water, m am is the monolayer capacity and C is a BET constant taking into account the adsorption heat of the first layer.

The FHH model is defined by the mathematical equation:

where m aFHH is the amount of adsorbed water vapor, the exponent \( \frac{1}{s} \) is related to the nature of the gas–solid interaction and K is an adjustable parameter which takes into account the energy of adsorption of the first layer. This model is complementary to the BET model; it allows the analysis of isotherms in the range of multilayer adsorption.

The GAB equation is expressed mathematically as follows:

where m aGAB is also the adsorbed amount of water vapor onto the polymer, C is Guggenheim constant related to the heat of condensation of water vapor at the given temperature and K is a factor for multilayer molecules with respect to bulk liquid.

The constants of the equations were estimated by regression analysis with using kaleida graph software. To evaluate the efficiency of each model, the coefficient of correlation was also reported. Given that desorption branch is reproducible during numerous cycles adsorption–desorption, selected models were fitted to the desorption branch. Correlation of experimental data to BET, GAB, and FHH equations at 298 K is shown in Figs. 5, 6, and 7. The parameters derived from each model are summarized in Table 1.

Modelisation figures display that FHH model overestimates the experimental data at the range of relative pressure below 0.1. They also show that GAB model is relatively the adequate one to describe the adsorption isotherms of water vapor on polyacrylic polymer. This result is confirmed by the values of correlation coefficient. In fact, the high value of this parameter is obtained for GAB model.

Table 1 indicates that the value of amounts adsorbed corresponding to the “equivalent monolayer” estimated by the three models is relatively equal at a given temperature. The obtained result also shows that the value of BET constant, Guggenheim constant, and the parameter S derived from FHH model decrease with increasing temperature, while the value of adjustable parameter K rises. The value of adsorbed amount corresponding to “equivalent monolayer” is about 16 mass%. Such value is practically similar to the theoretical value which is about 18 mass%.

Conclusions

This thermodynamic study of water vapor adsorption on polyacrylic polymer was based on the establishment and analysis of adsorption isotherms as well as the measurement of adsorption enthalpies. The adsorption isotherms were carried out by thermogravimetric method. They have type II isotherm shape indicating a hysteresis loop. Differential scanning was used to determine the adsorption heats. The measured values indicate two domains. The experimental data allows designing an adsorption mechanism in two steps. The water vapor molecules were adsorbed on the specific sites of adsorption located on the surface and between macromolecular chains. This amount of adsorbed “bounded water” forms the equivalent monolayer. Then the adsorption process occurs as condensation process, which causes the swelling of polymeric network. The test of reproducibility of adsorption–desorption process shows that the polymeric matrix undergoes a structural rearrangements during the first adsorption. The adopted form became stable during the following cycles. Among the sorption isotherm models chosen to describe the experimental data, GAB model provides a better fit of water vapor adsorption isotherm.

References

Elmchaouri A, Simonot-Grange MH, Mahboub R. Water vapour adsorption onto Ca2+ Camp-Berteau montmorillonite and comparison with properties of Na+ sample. Thermochim Acta. 2004;421:193–201.

Montes-H G, Geraud Y. Sorption Kinetic of water vapour of MX 80 bentonite submitted to different physical–chemical and mechanical conditions. Colloid Surface A. 2004;235:17–23.

Kabeel AE. Adsorption–desorption operations of multilayer desiccant packed bed for dehumidification applications. Renew Energ. 2009;34:255–65.

Egrdoğan AB, Sakici M, Yörükoğullari E, Yilmaz Y, Güven M. Thermal behavior and water adsorption of natural and modified sepiolite having dolomite from Turkey. J Therm Anal. 2008;94:835–40.

Krisztina L, Cyrille R, Geissler E. Water vapour adsorption and contrast-modified SAXS in microporous polymer-based carbons of different surface chemistry. J Therm Anal. 2008;14:447–55.

Wiśniewska M. Temperature effect on adsorption properties of silica–polyacrylic acid interface. J Therm Anal. 2010;101:753–60.

Torribio F, Bellat JP, Nguyen PH, Dupont M. Adsorption of water vapor by poly(styrenesulfonic acid), sodium salt: isothermal and isobaric adsorption equilibria. J Colloid Interface Sci. 2004;280:315–21.

Bakass M, Mokhlisse A, Lallemant M. Adsorption et desorption de l’eau vapeur sur un polymère polyacrylique superabsorbant. Partie 1: Isothermes et chaleurs d’adsorption de l’eau vapeur sur le polymlère. Thermochim Acta. 1992;204:205–12.

Bakass M, Mokhlisse A, Lallemant M, Benchanaa M. Adsorption et desorption de l’eau vapeur sur un polymère polyacrylique superabsorbant. Partie 3: Rôle de l’effet thermique local sur la cinétique d’adsorption. Thermochim Acta. 1993;223:271–9.

Bakass M, Mokhlisse A, Lallemant M. Adsorption et desorption de l’eau vapeur sur un polymère polyacrylique superabsorbant. IV: Affet de la masse sur les cinétiques d’adsorption et de désorption. Thermochim Acta. 1997;290:227–38.

Erdogan M, Capan i, Tarimci ç, Hassan AK. Modeling of vapor sorption in polymeric film studied by surface plasmon resonance spectroscopy. J Colloid Interface Sci. 2008;323:235–41.

Huang J, Zhou Y, Huang K, Liu S, Luo Q, Xu M. Adsorption behavior, thermodynamics, and mechanism of phenol on polymeric adsorbents with amide group in cyclohexane. J Colloid Interface Sci. 2007;316:10–8.

Li H, Xu M, Shi Z, He B. Isotherm analysis of phenol adsorption on polymeric adsorbents from aqueous solution. J Colloid Interface Sci. 2004;271:47–54.

Huang J, Huang K, Liu S, Luo Q, Xu M. Adsorption properties of tea polyphenols onto three polymeric adsorbents with amide group. J Colloid Interface Sci. 2007;315:407–14.

Huang J. Adsorption properties of a microporous and mesoporous hyper-crosslinked polymeric adsorbent functionalized with phenoxy groups for phenol. J Colloid Interface Sci. 2009;339:296–301.

Teichroeb JH, Forrest JH, Jones LW, Chan J, Dalton K. Quartz crystal microbalance study of protein adsorption kinetics on poly(2-hydroxyethyl methacrylate). J Colloid Interface Sci. 2008;325:157–64.

Popelka S, Machova L, Rypáček F. Adsorption of poly(ethylene oxide)-block-polylactide copolymers on polylactide as studied by ATR–FTIR spectroscopy. J Colloid Interface Sci. 2007;308:291–9.

Czanderna AW. Polymers as advanced materials for desiccant applications. Asharae Trans. 1989;95:1098–108.

Simont-Grange MH, Bertrand O, Pilverdier E, Bellat JP, Paulin C. Differential calorimetric enthalpies of adsorption of p-Xylene on Y Faujasites at 25 °C. J Therm Anal. 1997;48:741–54.

Brunauer S, Emmet PH, Teller E. Adsorption of gases in multimolecular layers. J Am Chem Soc. 1938;60:309–19.

Anderson RB. Modification of the Brunauer, Emmet and Teller Equation. J Am Chem Soc. 1946;68:686–91.

Hartley ID. Application of the Guggenheim-Anderson-DeBoer sorption isotherm model to Klinki Pine. Holforschung. 2000;54:661–3.

Pradas MM, Sanchez MS, Ferrer GG. Thermodynamics and statistical mechanics of multilayer adsorption. J Chem Phys. 2004;21:8524–31.

Helsey G. Physical adsorption on non-uniform surfaces. J Am chem Phys. 1948;16:931–7.

Hill TL. Theory of physical adsorption. Adv Catal. 1952;4:211–58.

Bahaj H, Benaddi R, Bakass M, Bayane C. Swelling of superabsorbents polymers in an aqueous medium. J Appl Polym Sci. 2010;115:2479–84.

Bakass M, Bellat JP, Bertrand G. Characterization of a superabsorbent polymer. J Appl Polym Sci. 2007;104:782–6.

Sing KSW, Everett DH, Haul RAW, Moscou L, Pieroti RA, Roouquerol J, Siemiewska T. Reporting physisorption data for gas/solids systems with special reference to the determination of surface area and porosity. Pure Appl Chem. 1985;57:603–19.

Yan Y, Sousa-Gallagher M, Oliveira FAR. Sorption isotherms and moisture sorption hysteresis of intermediate moisture content banana. J Food Eng. 2008;86:342–8.

Touati B. Etude théorique et expérimentale du séchage solaire des feuilles de la menthe verte (Mentha verdis). Thèse INSA de Lyon. 2008. http://docinsa.insa-lyon.fr/these/pont.php?id=touati.

Author information

Authors and Affiliations

Corresponding author

Additional information

It was presented at JEEP2010 Montpellier, France

Rights and permissions

About this article

Cite this article

Bahaj, H., Bakass, M., Bayane, C. et al. Modeling of water vapor adsorption isotherms onto polyacrylic polymer. J Therm Anal Calorim 103, 117–123 (2011). https://doi.org/10.1007/s10973-010-1075-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-1075-3