Abstract

SiO2-based phase change composites were prepared by sol–gel method using different phase change materials (PCMs), including stearic acid (SA), paraffin, and polyethylene glycol (PEG), and the effects of various mass fractions of PCMs were comprehensively investigated. The structures and thermal properties of these composites were characterized and analyzed by differential scanning calorimetry (DSC), X-ray diffraction (XRD), field emission scanning electron microscopy, and nitrogen adsorption–desorption measurements. The XRD and DSC results showed that the crystallinity and thermal enthalpy of paraffin in composite were the best among the three types of PCMs confined in SiO2. However, PEG in composites showed poor crystallinity and thermal enthalpy. After the extraction of the PCMs, the pore size distribution of SiO2 matrix and SEM images showed that SA/SiO2 composites possessed mesopores (20 nm) and macropores (50–150 nm), paraffin/SiO2 composites possessed mesopores and very large pores (2 μm), and PEG/SiO2 composites contained only mesopores. Among the three types of composites, paraffin/SiO2 composites exhibited the least mesopore volume. Presence of more mesopores in the composite led to worse crystallinity and thermal enthalpy of PCMs in composites. The crystallinity and thermal enthalpy of PCMs in composites were affected by the pore size and volume.

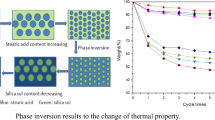

Graphical Abstract

Mesopores confined the crystallization and thermal behavior.

Similar content being viewed by others

References

Zalba B, Marın JM, Cabeza LF, Mehling H (2003) Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl Therm Eng 23:251–283

Cho JS, Kwon A, Cho CG (2002) Microencapsulation of octadecane as a phase-change material by interfacial polymerization in an emulsion system. Colloid Polym Sci 280:260–266

Agyenim F, Hewitt N, Eames P, Smyth M (2010) A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew Sustain Energy Rev 14:615–628

Sebaii AA, Ghamdi AA, Hazmi FS, Faidah AS (2009) Thermal performance of a single basin solar still with PCM as a storage medium. Appl Energy 86:1187–1195

Xia L, Zhang P (2011) Thermal property measurement and heat transfer analysis of acetamide and acetamide/expanded graphite composite phase change material for solar heat storage. Sol Energy Mater Sol Cells 95:2246–2254

Kuznik F, Virgone J (2009) Experimental assessment of a phase change material for wall building use. Appl Energy 86:2038–2046

Sánchez P, Sánchez-Fernandez MV, Romero A, Rodríguez JF, Sánchez-Silva L (2010) Development of thermo-regulating textiles using paraffin wax microcapsules. Thermochim Acta 498:16–21

Xiao X, Zhang P, Li M (2013) Preparation and thermal characterization of paraffin/metal foam composites phase change material. Appl Energy 112:1357–1366

Jin ZG, Wang YD, Liu JG, Yang ZZ (2008) Synthesis and properties of paraffin capsules as phase change materials. Polymer 49:2903–2910

Zhang X, Fan Y, Tao X, Yick K (2004) Fabrication and properties of microcapsules and nanocapsules containing n-octadecane. Mater Chem Phys 88:300–307

Fu Z, Su L, Li J, Yang R, Zhang Z, Liu M et al (2014) Elastic silicone encapsulation of n-hexadecyl bromide by microfluidic approach as novel microencapsulated phase change materials. Thermochim Acta 590:24–29

Zhang H, Wang X, Wu D (2010) Silica encapsulation of n-octadecane via sol–gel process: a novel microencapsulated phase-change material with enhanced thermal conductivity and performance. J Colloid Interface Sci 343:246–255

Fang G, Li H, Chen Z, Liu X (2011) Preparation and properties of palmitic acid/SiO2 composites with flame retardant as thermal energy storage materials. Sol Energy Mat Sol Cells 95:1875–1881

Yang H, Feng L, Wang C, Zhao W, Li X (2012) Confinement effect of SiO2 framework on phase change of PEG in shape-stabilized PEG/SiO2 composites. Eur Polym J 48:803–810

Qian T, Li J, Ma H, Yang J (2015) The preparation of a green shape-stabilized composite phase change material of polyethylene glycol/SiO2 with enhanced thermal performance based on oil shale ash via temperature-assisted sol–gel method. Sol Energy Mater Sol Cells 132:29–39

Li M, Wu Z, Tan J (2012) Properties of form-stable paraffin/silicon dioxide/expanded graphite phase change composites prepared by sol–gel method. Appl Energy 92:456–461

He L, Li J, Zhou C, Zhu H, Cao X, Tang B (2014) Phase change characteristics of shape-stabilized PEG/SiO2 composites using calcium chloride-assisted and temperature—assisted sol gel method. Sol Energy 103:448–455

Tang B, Cui J, Wang Y, Jia C, Zhang S (2013) Facile synthesis and performances of PEG/SiO2 composite form-stable phase change materials. Sol Energy 97:484–492

Jackson CL, McKenna GB (1990) The melting behavior of organic materials confined in porous solids. J Chem Phys 93:9002–9011

Leofanti G, Padovan M, Tozzola G, Venturelli B (1998) Surface area and pore texture of catalysts. Catal Today 41:207–219

Kondou S, Ishikawa T, Abe I (2001) Adsorption science, 2nd edn. Maruzen, Tokyo (in Japanese)

Acknowledgments

We would like to thank the Fund of China Academy of Engineering Physics (2014B0302052) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, Z., Su, L., Liu, M. et al. Confinement effect of silica mesopores on thermal behavior of phase change composites. J Sol-Gel Sci Technol 80, 180–188 (2016). https://doi.org/10.1007/s10971-016-4055-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4055-7