Abstract

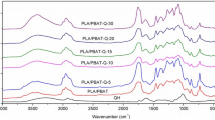

The increasing worldwide waste of polymers and agricultural products has prompted a pressing need for biodegradable plastic to help protect the environment. Hence, this research focuses on polybutylene adipate-co-terephthalate (PBAT) biodegradable polymers containing between 30–50 percent of filler to achieve an optimal balance of mechanical properties and biodegradation. Given its high lignin content, rice husk (RH) has displayed comparable properties to those of commercial lignin, and thus, the lignin from the rice husk was modified with acrylic acid grafting to facilitate the composite fabrication process. Fourier transform infrared (FTIR) analysis was used to demonstrate the grafting synergy and verify that the lignin/rice husk had been successfully grafted with the acrylic acid grafting process. Subsequently, the acrylic acid grafted lignin/rice husk was incorporated into PBAT to create a PBAT composite containing 30–50% AA lignin. The results revealed that the lignin: PBAT ratio at 30:70 (P70L30) resulted in the most optimum mechanical properties and biodegradability. These included tensile strength of 19.48 MPa, elongation at break of 20.26 MPa, Young’s modulus of 1913.62%, and crystallinity of 31.45%. The biodegradation of P70L30 was 57.36% over the 6 months, which was faster than the 9.2% degradation of PBAT. Additionally, the water absorption of P70L30 was two times more compared to PBAT, indicating the change in hydrophobicity of PBAT to a hydrophilic composite. Agricultural waste-rice husk displayed identical properties to lignin when incorporated into PBAT and resulting in the mechanical properties of strength, elongation at yield, and Young’s modulus of 19.09 MPa, 21.87%, and 1936.98 MPa. The mechanical properties and biodegradability of P70L30 on both lignin/rice husk in PBAT composite demonstrated the potential of affordable materials to create sustainable packaging solutions with good biodegradability and added features.

Similar content being viewed by others

Data Availability

The data presented in this study are available on request from the corresponding author.

References

United States Environmental Protection Agency (2018) EPA. In: United States Environ. Prot. Agency. https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf

Eurostat (2021) Waste statistics in the European Union. https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Packaging_waste_statistics

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:25–29. https://doi.org/10.1126/sciadv.1700782

Ilyas RA, Sapuan SM, Kadier A et al (2020) Properties and Characterization of PLA, PHA, and Other Types of Biopolymer Composites. Elsevier Inc

World Bank (2012) Solid Waste Management in the World’s Cities. World Bank, Washington, DC

Antić-Mladenović S, Frohne T, Kresović M et al (2017) Biogeochemistry of Ni and Pb in a periodically flooded arable soil: Fractionation and redox-induced (im)mobilization. J Environ Manage 186:141–150. https://doi.org/10.1016/j.jenvman.2016.06.005

Heidarzadeh N, Rafizadeh M, Taromi FA et al (2017) Biodegradability and biocompatibility of copoly(butylene sebacate-co-terephthalate)s. Polym Degrad Stab 135:18–30. https://doi.org/10.1016/j.polymdegradstab.2016.11.013

Benavides PT, Lee U, Zarè-Mehrjerdi O (2020) Life cycle greenhouse gas emissions and energy use of polylactic acid, bio-derived polyethylene, and fossil-derived polyethylene. J Clean Prod 277:. https://doi.org/10.1016/j.jclepro.2020.124010

Jian J, Xiangbin Z, Xianbo H (2020) An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv Ind Eng Polym Res 3:19–26. https://doi.org/10.1016/j.aiepr.2020.01.001

Dammak M, Fourati Y, Tarrés Q et al (2020) Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind Crops Prod 144:. https://doi.org/10.1016/j.indcrop.2019.112061

Havstad MR, Juroš L, Katančić Z, Pilipović A (2021) Influence of home composting on tensile properties of commercial biodegradable plastic films. Polymers (Basel) 13:. https://doi.org/10.3390/polym13162785

Kanwal A (2021) Polymer pollution and its solutions with special emphasis on Poly (butylene adipate terephthalate (PBAT)). Polym Bull. https://doi.org/10.1007/s00289-021-04065-2

Agrawal R, Kumar A, Singh S, Sharma K (2022) Recent advances and future perspectives of lignin biopolymers. J Polym Res 29:222. https://doi.org/10.1007/s10965-022-03068-5

Yang S, Yuan TQ, Shi Q, Sun RC (2018) Application of lignin in thermoplastic materials. J Encycl Sustain Sci Technol 1–22

Liu Y, Liu S, Liu Z et al (2021) Enhanced mechanical and biodegradable properties of PBAT/lignin composites via silane grafting and reactive extrusion. Compos Part B Eng 220:108980. https://doi.org/10.1016/j.compositesb.2021.108980

Xiong SJ, Pang B, Zhou SJ et al (2020) Economically Competitive Biodegradable PBAT/Lignin Composites: Effect of Lignin Methylation and Compatibilizer. ACS Sustain Chem Eng 8:5338–5346. https://doi.org/10.1021/acssuschemeng.0c00789

Yang Y, Zhang C, Weng Y (2021) Effects of CaCO3 surface modification and water spraying on the weathering properties of PBAT/CaCO3 films. Polym Test 102:. https://doi.org/10.1016/j.polymertesting.2021.107334

Hossain SKS, Mathur L, Roy PK (2018) Rice husk/rice husk ash as an alternative source of silica in ceramics: A review. J Asian Ceram Soc 6:299–313. https://doi.org/10.1080/21870764.2018.1539210

Nguyen NT, Tran NT, Phan TP et al (2022) The extraction of lignocelluloses and silica from rice husk using a single biorefinery process and their characteristics. J Ind Eng Chem 108:150–158. https://doi.org/10.1016/j.jiec.2021.12.032

Figueiredo P, Lintinen K, Hirvonen JT et al (2018) Properties and chemical modifications of lignin: Towards lignin-based nanomaterials for biomedical applications. Prog Mater Sci 93:233–269. https://doi.org/10.1016/j.pmatsci.2017.12.001

Joutey NT, Bahafid W, Sayel H, El Ghachtouli N (2013) Biodegradation: Involved Microorganisms and Genetically Engineered Microorganisms

Muthusamy Subramanian AV, Thanigachalam M (2022) Mechanical performances, in-vitro antibacterial study and bone stress prediction of ceramic particulates filled polyether ether ketone nanocomposites for medical applications. J Polym Res 29:318. https://doi.org/10.1007/s10965-022-03180-6

Ibrahim MNM, Iqbal A, Shen CC et al (2019) Synthesis of lignin based composites of TiO2 for potential application as radical scavengers in sunscreen formulation. BMC Chem 13:1–15. https://doi.org/10.1186/s13065-019-0537-3

Kubovský I, Kačíková D, Kačík F (2020) Structural changes of oak wood main components caused by thermal modification. Polymers (Basel) 12:. https://doi.org/10.3390/polym12020485

Porkodi P, A JK, Sunil S et al (2021) Lignin addition to polyacrylonitrile copolymer solution and its effect on the properties of carbon fiber precursor. J Polym Res 28:54. https://doi.org/10.1007/s10965-021-02420-5

Cichosz S, Masek A (2020) IR study on cellulose with the varied moisture contents: Insight into the supramolecular structure. Materials (Basel) 13:1–22. https://doi.org/10.3390/ma13204573

Ryu SR, Noda I, Jung YM (2011) Positional Fluctuation of IR Absorption Peaks: Frequency Shift of a Single Band or Relative Intensity Changes of Overlapped Bands? Am Lab

Podkos̈cielna B, Sobiesiak M, Zhao Y et al (2015) Preparation of lignin-containing porous microspheres through the copolymerization of lignin acrylate derivatives with styrene and divinylbenzene. Holzforschung 69:769–776. https://doi.org/10.1515/hf-2014-0265

Martín JA, Solla A, Woodward S, Gil L (2005) Fourier transform-infrared spectroscopy as a new method for evaluating host resistance in the Dutch elm disease complex. Tree Physiol 25:1331–1338. https://doi.org/10.1093/treephys/25.10.1331

Adam F, Appaturi JN, Thankappan R, Nawi MAM (2010) Silica-tin nanotubes prepared from rice husk ash by sol-gel method: Characterization and its photocatalytic activity. Appl Surf Sci 257:811–816. https://doi.org/10.1016/j.apsusc.2010.07.070

Abderrahim B, Abderrahman E, Mohamed A et al (2015) Kinetic Thermal Degradation of Cellulose, Polybutylene Succinate and a Green Composite: Comparative Study. World J Environ Eng Vol 3, 2015, Pages 95–110 3:95–110. https://doi.org/10.12691/WJEE-3-4-1

Ma’Ruf A, Pramudono B, Aryanti N (2017) Lignin isolation process from rice husk by alkaline hydrogen peroxide: Lignin and silica extracted. AIP Conf Proc 1823:. https://doi.org/10.1063/1.4978086

Appaturi JN, Adam F, Khanam Z (2012) A comparative study of the regioselective ring opening of styrene oxide with aniline over several types of mesoporous silica materials. Microporous Mesoporous Mater 156:16–21. https://doi.org/10.1016/j.micromeso.2012.01.023

Azmi MA, Ismail NAA, Rizamarhaiza M et al (2016) Characterisation of silica derived from rice husk (Muar, Johor, Malaysia) decomposition at different temperatures. AIP Conf Proc 1756:. https://doi.org/10.1063/1.4958748

Chen RS, Salleh MN, Ghani MHA et al (2015) Biocomposites Based on Rice Husk Flour and Recycled Polymer Blend: Effects of Interfacial Modification and High Fibre Loading. BioResources 10:6872–6885. https://doi.org/10.15376/biores.10.4.6872-6885

da Silva JBA, Santana JS, de Almeida Lucas A et al (2019) PBAT/TPS-nanowhiskers blends preparation and application as food packaging. J Appl Polym Sci 136:. https://doi.org/10.1002/app.47699

Ming M, Zhou Y, Wang L et al (2022) Effect of polycarbodiimide on the structure and mechanical properties of PLA/PBAT blends. J Polym Res 29:371. https://doi.org/10.1007/s10965-022-03227-8

Yap SY, Sreekantan S, Hassan M et al (2020) Characterization and Biodegradability of Rice Husk-Filled Polymer Composites. Polymers (Basel) 13:104. https://doi.org/10.3390/polym13010104

Yi T, Qi M, Mo Q et al (2020) Ecofriendly preparation and characterization of a cassava starch/polybutylene adipate terephthalate film. Processes 8:. https://doi.org/10.3390/pr8030329

Kang SM, Ahn JY, Kim YB, Choi DK (2004) Influence of the Electric Field on the Ni-Lnduced Low-Temperature Crystallization of Amorphous Silicon Films. J Korean Phys Soc 44:177–180

Chemtec Publishing (2016) EFFECT OF NUCLEATING AGENTS ON PHYSICAL-MECHANICAL PROPERTIES. Handb Nucleating Agents

Klapiszewski Ł, Grząbka-Zasadzińska A, Borysiak S, Jesionowski T (2019) Preparation and characterization of polypropylene composites reinforced by functional ZnO/lignin hybrid materials. Polym Test 79:. https://doi.org/10.1016/j.polymertesting.2019.106058

Jakob M, Mahendran AR, Gindl-Altmutter W, Bliem P, Konnerth J, Mueller U, Veigel S (2021) The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog Mater Sci. https://doi.org/10.1016/j.pmatsci.2021.100916

Wei B, Zhao Y, Wei Y et al (2019) Morphology and Properties of a New Biodegradable Material Prepared from Zein and Poly(butylene adipate-terephthalate) by Reactive Blending. ACS Omega 4:5609–5616. https://doi.org/10.1021/acsomega.9b00210

Alipoormazandarani N, Fatehi P (2020) Lignin-methyl methacrylate polymer as a hydrophobic multifunctional material. Ind Crops Prod 154:112728. https://doi.org/10.1016/j.indcrop.2020.112728

Roychowdhury T, Cushman CV, Major G, Linford MR (2015) The Surface Analytical Chemistry (XPS) and Polymer Chemistry of the Acrylates and Methacrylates, an Introduction. Vac Technol Coat

Zhou H, Liu W, Zhang B, Xue Y, Tang Z (2022) Regulation of hydrophilic performance for chlorinated polyethylene grafting acrylic acid via co-irradiation. Mater Lett. https://doi.org/10.1016/j.matlet.2021.131576

Rassiah K, Sin TW, Ismail MZ (2016) A study on flexural and water absorption of surface modified rice husk flour/E-glass/polypropylene hybrid composite. IOP Conf Ser Mater Sci Eng 152:. https://doi.org/10.1088/1757-899X/152/1/012061

Yang B, Nagarajan B, Mertiny P (2021) Characterization of swelling behavior of carbon nano-filler modified polydimethylsiloxane composites. J Elastomers Plast 53:955–974. https://doi.org/10.1177/00952443211006156

Ballantine DS Jr, Martin SJ, Ricco AJ,Frye GC, Wohltjen H, White RM, Zellers ET (1997) Chapter 4 - Materials Characterization. In: Acoustic Wave Sensors: Theory, Design and Physico-Chemical Applications. pp 150–221

Skleničková K, Abbrent S, Halecký M et al (2022) Biodegradability and ecotoxicity of polyurethane foams: A review. Crit Rev Environ Sci Technol 52:157–202. https://doi.org/10.1080/10643389.2020.1818496

Fukushima K, Rasyida A, Yang MC (2013) Biocompatibility of organically modified nanocomposites based on PBAT. J Polym Res 20:. https://doi.org/10.1007/s10965-013-0302-6

Acknowledgements

The authors thank the Ministry of Higher Education for providing the Fundamental Research Grant Scheme (FRGS) (FRGS/1/2021/TK0/USM/01/1). The authors thank Universiti Sains Malaysia (USM) for providing the necessary facilities for this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

Informed consent was not obtained as no human participants were involved in this study.

Conflict of interest

Hong Han Choo, Srimala Sreekantan and Jimmy Nelson Appaturi declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choo, H.H., Sreekantan, S. & Appaturi, J.N. Preparation, characterization and biodegradability of acrylate graft rice husk/ lignin reinforced PBAT. J Polym Res 30, 377 (2023). https://doi.org/10.1007/s10965-023-03760-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03760-0