Abstract

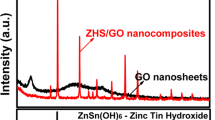

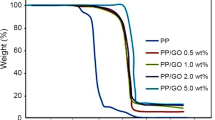

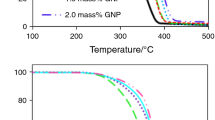

In the contribution, magnesium hydroxides and graphene oxide were synergistically combined to prepare the chip-in-flakes nanohybrid (Mg(OH)2/GO, MGO) via one-step hydrothermal approach for improving fire retardancy of polypropylene. Various characterizations confirmed its composition, structure and morphology. The fire-retardant evaluations illustrated that limiting oxygen index (LOI) of PP composite with 50 wt.% MGO was improved to 27.8% with UL-94 V-0 rating compared with virgin PP (17.4%, no rating). In parallel, the peak heat release rate, total heat release and smoke production rate of PP/MGO (PMG) were reduced by 80.5%, 30.8% and 79.4% respectively. The mechanism investigation uncovered that the conspicuous fire retardancy and smoke suppression were credited to the synergistic effect between GO and Mg(OH)2 toward the optimized physical barrier. Furthermore, dynamic mechanical analysis (DMA) disclosed the highest modulus (8043 MPa) at -71 °C relative to 3236 MPa of pure PP. In viewpoint, hierarchical nano-flakes with synergistic effect offered an effective approach for the fire-safe polymer.

Similar content being viewed by others

References

Zhang X, Zhao S, Meng X, Xin Z (2020) J Polym Res 27:303. https://doi.org/10.1007/s10965-020-02260-9

Zhang Q, Zhan J, Zhou K, Lu H, Zeng W, Stec AA et al (2015) Polym Degrad Stab 115:38–44. https://doi.org/10.1016/j.polymdegradstab.2015.02.010

Wu K, Xu S, Tian XY, Zeng HY, Hu J, Guo YH et al (2021) Int J Biol Macromol 178:580–590. https://doi.org/10.1016/j.ijbiomac.2021.02.148

Nie S, Wu W, Pan Y, Dong X, Li B, Wang D-Y (2018) Fire Mater 42:703–709. https://doi.org/10.1002/fam.2523

Zubkiewicz A, Szymczyk A, Paszkiewicz S, Jędrzejewski R, Piesowicz E, Siemiński J (2020) J Appl Polym Sci 137:49135. https://doi.org/10.1002/app.49135

Hu C, Bourbigot S, Delaunay T, Collinet M, Marcille S, Fontaine G (2020) Compos B Eng 184:107675. https://doi.org/10.1016/j.compositesb.2019.107675

Tan Y, Shao ZB, Chen XF, Long JW, Chen L, Wang YZ (2015) ACS Appl Mater Interfaces 7:17919–17928. https://doi.org/10.1021/acsami.5b04570

Chen H, Wang T, Wen Y, Wen X, Gao D, Yu R et al (2019) Compos B Eng 177:107402. https://doi.org/10.1016/j.compositesb.2019.107402

Yao D, Yin G, Bi Q, Yin X, Wang N, Wang D-Y (2020) Polymers (Basel) 12. https://doi.org/10.3390/polym12092107

Liu T, Wang F, Li G, Liu P, Gao C, Ding Y et al (2020) J Appl Polym Sci 138:49607. https://doi.org/10.1002/app.49607

Liu Z, Zhang Y, Li N, Wen X, Nogales LA, Li L et al (2018) J Therm Anal Calorim 136:601–608. https://doi.org/10.1007/s10973-018-7669-x

Fu M, Qu B (2004) Polym Degrad Stab 85:633–639. https://doi.org/10.1016/j.polymdegradstab.2004.03.002

Liu J, He Y, Chang H, Guo Y, Li H, Pan B (2020) Polym Degrad Stab 171:109051. https://doi.org/10.1016/j.polymdegradstab.2019.109051

Yen Y-Y, Wang H-T, Guo W-J (2012) Polym Degrad Stab 97:863–869. https://doi.org/10.1016/j.polymdegradstab.2012.03.043

Zhang G, Ding P, Zhang M, Qu B (2007) Polym Degrad Stab 92:1715–1720. https://doi.org/10.1016/j.polymdegradstab.2007.06.004

Song L, Zhou S, Wu J, Hu Y (2009) Polym-Plast Technol Eng 48:1088–1093. https://doi.org/10.1080/03602550903147205

Carpentier F, Bourbigot S, Bras ML, Delobel R, Foulon M (2000) Polym Degrad Stab 69:83–92. https://doi.org/10.1016/S0141-3910(00)00044-6

Li Z, Liu Z, Zhang J, Fu C, Wagenknecht U, Wang D-Y (2019) Chem Eng J 378:122046. https://doi.org/10.1016/j.cej.2019.122046

Cai W, Cai T, He L, Chu F, Mu X, Han L et al (2020) J Hazard Mater 387:121971. https://doi.org/10.1016/j.jhazmat.2019.121971

Qu L, Sui Y, Zhang C, Li P, Dai X, Xu B et al (2020) Eur Polymer J 122:109383. https://doi.org/10.1016/j.eurpolymj.2019.109383

Yu B, Tawiah B, Wang LQ, Yuen A, Zhang ZC, Shen LL et al (2019) J Hazard Mater 374:110–119. https://doi.org/10.1016/j.jhazmat.2019.04.026

Zhu Y, Murali S, Cai W, Li X, Suk JW, Potts JR et al (2010) Adv Mater 22:3906–3924. https://doi.org/10.1002/adma.201001068

Shi X, Peng X, Zhu J, Lin G, Kuang T (2018) J Colloid Interface Sci 524:267–278. https://doi.org/10.1016/j.jcis.2018.04.016

Xu J, Liu J, Li K (2015) Journal of Vinyl & Additive. Technology 21:278–284. https://doi.org/10.1002/vnl.21415

Huang G, Liang H, Wang Y, Wang X, Gao J, Fei Z (2012) Mater Chem Phys 132:520–528. https://doi.org/10.1016/j.matchemphys.2011.11.064

Liu ZQ, Li Z, Yang YX, Zhang YL, Wen X, Li N, et al (2018) Polymers (Basel). https://doi.org/10.3390/polym10091028

Chen J, Yao B, Li C, Shi G (2013) Carbon 64:225–229. https://doi.org/10.1016/j.carbon.2013.07.055

Hummers SW, Offeman RE (1958) J Am Chem Soc 80:1339. https://doi.org/10.1021/ja01539a017

Maddalena L, Carosio F, Gomez J, Saracco G, Fina A (2018) Polym Degrad Stab 152:1–9. https://doi.org/10.1016/j.polymdegradstab.2018.03.013

Si Y, Samulski ET (2008) Nano Lett 8:1679–1682. https://doi.org/10.1021/nl080604h

Wensel R, Penaloza M, Cross WM, Winter RM, Kellar JJ (1995) Langmuir 11:4593–4595. https://doi.org/10.1021/la00011a066

Pang H, Ning G, Gong W, Ye J, Lin Y (2011) Chem Commun (Camb) 47:6317–6319. https://doi.org/10.1039/c1cc10279f

Gong W, Wu D, Cheng Z, Pang H, Lin Y, Ning G (2013) Mater Res Bull 48:1333–1337. https://doi.org/10.1016/j.materresbull.2012.12.033

Bhargava R, Khan S (2017) Adv Powder Technol 28:2812–2819. https://doi.org/10.1016/j.apt.2017.08.008

Bradder P, Ling SK, Wang S, Liu S (2011) J Chem Eng Data 56:138–141. https://doi.org/10.1021/je101049g

Amrollahi S, Ramezanzadeh B, Yari H, Ramezanzadeh M, Mahdavian M (2019) Compos B Eng 173:106804. https://doi.org/10.1016/j.compositesb.2019.05.015

Kandola BK, Yenilmez A, Horrocks RA, Smart G, Kun W, Hu Y (2009) ACS Symp Ser 1013:47–69. https://doi.org/10.1021/bk-2009-1013.ch005

Wang B, Zhou K, Wang B, Gui Z, Hu Y (2014) Ind Eng Chem Res 53:12355–12362. https://doi.org/10.1021/ie502232a

Yuan B, Hu Y, Chen X, Shi Y, Niu Y, Zhang Y et al (2017) Compos A Appl Sci Manuf 100:106–117. https://doi.org/10.1016/j.compositesa.2017.04.012

Sun Y, Yuan B, Shang S, Zhang H, Shi Y, Yu B et al (2020) Compos B Eng 181:107588. https://doi.org/10.1016/j.compositesb.2019.107588

Wang R, Zhuo D, Weng Z, Wu L, Cheng X, Zhou Y et al (2015) J Mat Chem A 3:9826–9836. https://doi.org/10.1039/C5TA00722D

Weidenfeller B, Kirchberg S (2016) Compos B Eng 92:133–141. https://doi.org/10.1016/j.compositesb.2016.02.011

Hasegawa N, Okamoto H, Kato M, Usuki A (2000) J Appl Polym Sci 78:1918–1922. https://doi.org/10.1016/j.joen.2008.09.001

Acknowledgements

This research was partly funded the Natural Science Foundation of China (No. U1607104), the Science and Technology of Qinghai Program (2019-HZ-813, 2019-GX-163, 2020-GX-102 and 2020-GX-ZL07).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A chip-in-flakes structure nanohybrid Mg(OH)2-GO was synthesized via one-step hydrothermal method.

• 50 wt.% Mg(OH)2-GO endowed polypropylene with UL-94 V-0, reduced the release of toxic gases and improved the fire safety of PP.

• Mg(OH)2-GO remarkably improved the mechanical properties of PP matrix.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, F., Zhang, Y., Jia, Y. et al. Magnesium hydroxide/graphene oxide chip in flakes structure and its fire-retardant reinforcement of polypropylene. J Polym Res 28, 393 (2021). https://doi.org/10.1007/s10965-021-02764-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02764-y