Abstract

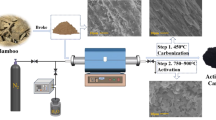

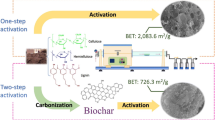

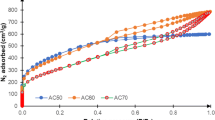

Unconventional pretreatment, that is, delignification and the addition of guanidine phosphate, was performed for the synthesis of activated carbon having a high specific surface area from bamboo by physical activation. The values of the specific surface area, total pore volume, and average pore size depended on the amount of added guanidine phosphate and the CO2 activation time. The amount of the added guanidine phosphate under the optimum conditions for the highest specific surface area was much lower than that of the phosphorous acid chemical activator under conventional conditions. The N2 adsorption isotherms of all the samples were type I, which means that micropores were dominant. The pore sizes of the samples in this study were similar to that of the physically-activated carbon. Therefore, the activation process was presumed to be essentially not chemical, but physical. The relation between the yield and the specific surface area improved with the addition of guanidine phosphate. The reason for the improvement may be the change in the reactivity of the carbon material generated during the heating process. The maximum specific surface area was ca. 2000 m2 g−1, which is a high value for a physically-activated carbon.

Similar content being viewed by others

References

A. Bhatnagar, W. Hogland, M. Marques, M. Sillanpaa, Chem. Eng. J. 219, 499 (2013)

J. Rivera-Utrilla, M. Sanchez-Polo, V. Gomez-Serrano, P.M. Alvarez, M.C.M. Alvim-Ferraz, J.M. Dias, J. Hazard. Mater. 187, 1 (2011)

D. Qu, H. Shi, J. Power Source 74, 99 (1998)

O. Barbieri, M. Hahn, A. Herzog, R. Kotz, Carbon 43, 1303 (2005)

H. Shi, Electrochim. Acta 41, 1633 (1996)

C. Moreno-Castilla, J. Rivera-Utrilla, M.V. Lopez-Ramon, F. Carrasco-Marin, Carbon 33, 845 (1995)

S. Villar-Rodil, F. Suarez-Garcia, J.I. Paredes, A. Martinez-Alonso, J.M.D. Tascon, Chem. Mater. 17, 5893 (2005)

O. Ioannidou, A. Zabaniotou, Renew. Sustain. Energy Rev. 11, 1966 (2007)

M.J. Illan-Gomez, A. Garcia-Garcia, C.S.M. Lecea, A. LinaresSolano, Energy Fuel 10, 1108 (1996)

A. Aworn, P. Thiravetyan, W. Nakbanpote, J. Anal. Appl. Pyrolysis 82, 279 (2008)

C. Moreno-Castilla, F. Carrasco-Marin, M.V. Lopez-Ramon, M.A. Alvarez-Merino, Carbon 39, 1415 (2001)

M. Ruiz-Fernandez, M. Alexandre-Franco, C. Fernandez-Gonzalez, V. Gomez-Serrano, Adsorption 17, 621 (2011)

M.J. Prauchner, F. Rodriguez-Reinoso, Micropor. Mesopor. Mater. 152, 163 (2012)

M.J.D. Mahboub, A. Ahmadpour, H. Rashidi, N. Jahanshahi, Adsorption 18, 297 (2012)

Z.A. Zhang, M. Cui, Y.Q. Lai, J. Li, Y.X. Liu, J. Cent. South Univ. Technol. 16, 91 (2009)

M.B. Vazquez-Santos, A. Martinez-Alonso, J.M.D. Tascon, J. Anal. Appl. Pyrol. 95, 68 (2012)

T. Tsubota, Y. Miyauchi, N. Murakami, T. Ohno, J. Power Sources 196, 5769 (2011)

T. Tsubota, T. Yamaguchi, C.S. Wang, Y. Miyauchi, N. Murakami, T. Ohno, J. Power Sources 227, 24 (2013)

T. Tsubota, C.S. Wang, N. Murakami, T. Ohno, J. Power Sources 225, 150 (2013)

T. Tsubota, D. Nagata, N. Murakami, T. Ohno, J. Appl. Polym. Sci. 131, 40950 (2014)

P. Paraskeva, D. Kalderis, E. Diamadopoulos, J. Chem. Technol. Biotechnol. 83, 581 (2008)

A.C. Lua, J. Guo, Carbon 38, 1089 (2000)

S. Guo, J. Peng, W. Li, K. Yang, L. Zhang, S. Zhang, H. Xia, Appl. Surf. Sci. 255, 8443 (2009)

M.L.L. Sanchez, A. Macias-Garcia, M.A. Diaz-Diez, E.M. Cuerda-Correa, J. Ganan-Gomez, A. Nadal-Gisbert, Appl. Surf. Sci. 252, 5984 (2006)

X. Wang, D. Li, W. Li, J. Peng, H. Xia, L. Zhang, S. Guo, G. Chen, BioResources 8, 6184 (2013)

M. Benadjemia, L. Milliere, L. Reinert, N. Benderdouche, L. Duclaux, Fuel Process. Technol. 92, 1203 (2011)

A.M. Puziya, O.I. Poddubnaya, R.P. Socha, J. Gurgul, M. Wisniewski, Carbon 46, 2113 (2008)

Y. Sun, Q. Yue, B. Gao, Y. Wang, Y. Gao, Q. Li, Powder Technol. 249, 54 (2013)

H. Konno, T. Ito, M. Ushiro, K. Fushimi, K. Azumi, J. Power Sources 195, 1739 (2010)

A. Granzow, Accounts Chem. Res. 11, 177 (1978)

Acknowledgments

The dried bamboo powder used in this study was provided by Bamboo Chemical Laboratory Co., Ltd. The authors express our thanks to Masayuki Tsuruha, a representative of the Bamboo Chemical Laboratory Co., Ltd. The authors thank Prof. Yukie Saito of the Graduate School of Agricultural and Life Sciences, The University of Tokyo, for her advice about the delignification method. This work was supported by JSPS KAKENHI Grant No. 26410253 and the Yamagin regional enterprise support foundation.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Tsubota, T., Morita, M., Kamimura, S. et al. New approach for synthesis of activated carbon from bamboo. J Porous Mater 23, 349–355 (2016). https://doi.org/10.1007/s10934-015-0087-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-015-0087-6