Abstract

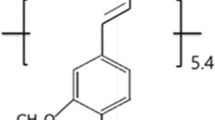

A modified sequential mass-suspension polymerization was employed to ensure adequate dispersion of lignin into the monomeric phase. Due to its complex macromolecular structure and low compatibility with styrene, eucalyptus wood-extracted lignin, via a modified Kraft method, was esterified with methacrylic anhydride to ensure organic phase homogeneity into the reaction medium. Infrared spectroscopy showed a decrease in the hydroxyl band, a characteristic of natural lignin (3200–3400 cm−1) and an increase in the characteristic ester band (1720–1740 cm−1) whereas nuclear magnetic resonance measurements exhibited intense peaks in the range from 1.7 to 2.05 ppm (–CH3) and 5.4 to 6.2 ppm (=CH2), related to methacrylic anhydride. Comparatively, the esterified lignin also displayed an increase of its glass transition temperature for 98 °C, related to natural lignin, whose T g was determined to be equal to 91 °C. Styrene/lignin-based polymers exhibited higher average molar masses in comparison to the values observed for polystyrene synthesized with similar amounts of benzoyl peroxide, due to the ability of lignin to act as a free-radical scavenger. Composites obtained with styrene and natural or esterified lignin were successfully synthesized, presenting regular morphology and proper lignin dispersion. Based on a very simple polymerization system, it is possible to enhance the final properties of polystyrene through the incorporation of lignin, which represents an important platform for developing attractive polymeric materials from renewable resources.

Reprinted with permission from reference [31]. Copyright © 2005, American Chemical Society

Similar content being viewed by others

References

Borsoi C, Scienza LC, Zattera AJ, Angrizani CC (2011) Obtenção e caracterização de compósitos utilizando poliestireno como matriz e resíduos de fibras de algodão da indústria têxtil como reforço. Polímeros 21:271–279

Santos RPO, Rodrigues BVM, Ramires EC, Ruvolo-Filho AC, Frollini E (2015) Bio-based materials from the electrospinning of lignocellulosic sisal fibers and recycled PET. Ind Crops Prod 72:69–76

Gordobil O, Delucis R, Egüés I, Labidi J (2015) Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind Crops Prod 72:46–53

Soroudi A, Jakubowicz I (2013) Recycling of bioplastics, their blends and biocomposites: a review. Eur Polym J 49:2839–2858

Ayoub A, Venditti RA, Jameel H, Chang H-M (2014) Effect of irradiation on the composition and thermal properties of softwood kraft lignin and styrene grafted lignin. J Appl Polym Sci 131:39743

Barton Ii FE (1988) Chemistry of lignocellulose: methods of analysis and consequences of structure. Anim Feed Sci Technol 21:279–286

Doherty WOS, Mousavioun P, Fellows CM (2011) Value-adding to cellulosic ethanol: Lignin polymers. Ind Crops Prod 33:259–276

Lewis NG, Yamamoto E (1990) Lignin: Occurrence, Biogenesis and Biodegradation. Annu Rev Plant Physiol Plant Mol Biol 41:455–496

F.d. Oliveira, Ramires EC, Frollini E, Belgacem MN (2015) Lignopolyurethanic materials based on oxypropylated sodium lignosulfonate and castor oil blends. Ind Crops Prod 72:77–86

Sun XS, Richard P. Wool (2005) Lignin polymers and composites. In: Books E.S.T. (ed) Bio-Based Polymers and Composites. Elsevier, Amsterdam, pp 551–598

Chauhan M, Gupta M, Singh B, Singh AK, Gupta VK (2014) Effect of functionalized lignin on the properties of lignin-isocyanate prepolymer blends and composites. Eur Polym J 52:32–43

Cohen JL, Fong GP (1975) Source of selectivity in the quantitative determination of alcohols by acylation with cyclic anhydrides. Anal Chem 47:313–316

Fox C (2006) Chemical and Thermal Characterization of Three Industrial Lignins and their Corresponding Lignin Esters. College of Graduate Studies, University of Idaho, Moscow

Thielemans W, Can E, Morye SS, Wool RP (2002) Novel applications of lignin in composite materials. J Appl Polym Sci 83:323–331

Wachowiak R, Connors KA (1979) N-Methylimidazole-catalyzed acetylation of hydroxy compounds prior to gas chromatographic separation and determination. Anal Chem 51:27–30

Bittner AS, Harris LE, Campbell WF (1980) Rapid N-methylimidazole-catalyzed acetylation of plant cell wall sugars. J Agric Food Chem 28:1242–1245

Dee LA, Biggers BL, Fiske ME (1980) N-Methylimidazole as a catalyst for acetylation of hydroxyl terminated polymers. Anal Chem 52:572–573

Holmberg AL, Nguyen NA, Karavolias MG, Reno KH, Wool RP, Epps TH (2016) Softwood lignin-based methacrylate polymers with tunable thermal and viscoelastic properties. Macromolecules 49:1286–1295

Jiang C, He H, Yao X, Yu P, Zhou L, Jia D (2015) In situ dispersion and compatibilization of lignin/epoxidized natural rubber composites: reactivity, morphology and property. J Appl Polym Sci 132:42044

Hilburg SL, Elder AN, Chung H, Ferebee RL, Bockstaller MR, Washburn NR (2014) A universal route towards thermoplastic lignin composites with improved mechanical properties. Polymer 55:995–1003

Shah T, Gupta C, Ferebee RL, Bockstaller MR, Washburn NR (2015) Extraordinary toughening and strengthening effect in polymer nanocomposites using lignin-based fillers synthesized by ATRP. Polymer 72:406–412

Dallmeyer I, Lin LT, Li Y, Ko F, Kadla JF (2014) Preparation and characterization of interconnected, kraft lignin-based carbon fibrous materials by electrospinning. Macromol Mater Eng 299:540–551

Fernandes EM, Pires RA, Mano JF, Reis RL (2013) Bionanocomposites from lignocellulosic resources: properties, applications and future trends for their use in the biomedical field. Prog Polym Sci 38:1415–1441

Kun D, Pukánszky B (2017) Polymer/lignin blends: interactions, properties, applications. Eur Polym J. doi:10.1016/j.eurpolymj.2017.04.035

Gouveia ER, R.T.d. Nascimento, Souto-Maior AM, G.J.d.M. Rocha (2009) Validação de metodologia para a caracterização química de bagaço de cana-de-açúcar. Química Nova 32:1500–1503

Saliba EOS, Rodriguez NM, de Morais SAL, Piló-Veloso D (2001) Ligninas: métodos de obtenção e caracterização química. Ciência Rural 31:917–928

Campelo NM, Machado F (2013) Reciclagem de Poli(estireno-divinilbenzeno) via Processo de Polimerização em Massa-Suspensão. Polímeros 23:212–222

Machado F, Lima EL, Pinto JC (2007) Uma revisão sobre os processos de polimerização em suspensão. Polímeros 17:166–179

Pinto MCC, Santos JGF, Machado F, Pinto JC (2002) Suspension Polymerization Processes, Encyclopedia of Polymer Science and Technology. Wiley, Hoboken

Wexler AS (1964) Characterization of lignosulfonates by ultraviolet spectrometry: direct and difference spectrograms. Anal Chem 36:213–221

Thielemans W, Wool RP (2005) Lignin esters for use in unsaturated thermosets: lignin modification and solubility modeling. Biomacromolecules 6:1895–1905

Connors KA, Pandit NK (1978) N-Methylimidazole as a catalyst for analytical acetylations of hydroxy compounds. Anal Chem 50:1542–1545

de Morais SAL, do Nascimento EA, de Melo DC (2005) Análise da madeira do Pinus oocarpa parte II : caracterização estrutural da lignina de madeira moída. Rev Árvore 29:471–478

Boeriu CG, Fiţigău FI, R.J.A. Gosselink, Frissen AE, Stoutjesdijk J, Peter F (2014) Fractionation of five technical lignins by selective extraction in green solvents and characterisation of isolated fractions. Ind Crops Prod 62:481–490

Yu Y, Li X, Su L, Zhang Y, Wang Y, Zhang H (2012) The role of shape selectivity in catalytic fast pyrolysis of lignin with zeolite catalysts. Appl Catal A 447–448:115–123

Gordobil O, Egüés I, Llano-Ponte R, Labidi J (2014) Physicochemical properties of PLA lignin blends. Polym Degrad Stab 108:330–338

Monteil-Rivera F, Paquet L (2015) Solvent-free catalyst-free microwave-assisted acylation of lignin. Ind Crops Prod 65:446–453

Sai Ram M, Palaniappan S (2003) Benzoyl peroxide oxidation route to polyaniline salt and its use as catalyst in the esterification reaction. J Mol Catal A 201:289–296

Odian G (2004) Principles of polimerization. Wiley, Hoboken

Ockenfels H-M, Uter W, Lessmann H, Schnuch A, Geier J (2009) Patch testing with benzoyl peroxide: reaction profile and interpretation of positive patch test reactions. Contact Dermat 61:209–216

Dashtban M, Schraft H, Syed TA, Qin W (2010) Fungal biodegradation and enzymatic modification of lignin. Int J Biochem Mol Biol 1:36–50

Koduri RS, Tien M (1995) Oxidation of guaiacol by lignin peroxidase: role of veratryl alcohol. J Biol Chem 270:22254–22258

Lange H, Decina S, Crestini C (2013) Oxidative upgrade of lignin: recent routes reviewed. Eur Polym J 49:1151–1173

Chatel G, Rogers RD (2014) Review: oxidation of lignin using ionic liquids: an innovative strategy to produce renewable chemicals. ACS Sustain Chem Eng 2:322–339

Behling R, Valange S, Chatel G (2016) Heterogeneous catalytic oxidation for lignin valorization into valuable chemicals: what results? What limitations? What trends? Green Chem 18:1839–1854

Crestini C, Crucianelli M, Orlandi M, Saladino R (2010) Oxidative strategies in lignin chemistry: a new environmental friendly approach for the functionalisation of lignin and lignocellulosic fibers. Catal Today 156:8–22

Ma R, Xu Y, Zhang X (2015) Catalytic oxidation of biorefinery lignin to value-added chemicals to support sustainable biofuel production. ChemSusChem 8:24–51

Aranha IB, Lucas EF (2001) Poli(Álcool Vinílico) Modificado com Cadeias Hidrocarbônicas: Avaliação do Balanço Hidrófilo/Lipófilo. Polímeros 11:174–181

Geller BE, Shcherbina LA, Korotkaya ON (2000) Effect of the acidity of the reaction medium on homophase copolymerization of acrylonitrile, methyl acrylate, and 2-acrylamide-2-methylphopanesulfonic acid in hydrotropic solvents, Fibre. Chemistry 32:111–115

Araujo RT, Ferreira GR, Segura T, Souza FG, Machado F (2015) An experimental study on the synthesis of poly(vinyl pivalate)-based magnetic nanocomposites through suspension polymerization process. Eur Polym J 68:441–459

Acknowledgements

The authors thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq), Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and Embrapa for the research support.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Victor, P.A., Gonçalves, S.B. & Machado, F. Styrene/Lignin-Based Polymeric Composites Obtained Through a Sequential Mass-Suspension Polymerization Process. J Polym Environ 26, 1755–1774 (2018). https://doi.org/10.1007/s10924-017-1078-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-017-1078-2