Abstract

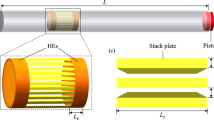

A piston is the key component of the diesel engine, which is subjected to higher pressure and temperature inside the combustion chamber. The wear propagation on piston leads to an increase in engine vibrations, acoustic emissions, exhaust emissions, lubricant degradation, reduction in the total power output and thermal efficiency of the engine. Hence, it is necessary to consider fault diagnostic techniques to detect the faults developed in the piston during the in-service condition. In this experimental work, efforts were made to detect the piston scuffing fault using vibration and acoustic emission analyses. The fault-related features were extracted from vibro-acoustic signals using signal processing tools viz. fast Fourier transform and continuous wavelet transform. The performance parameters such as brake power, brake thermal efficiency, brake specific fuel consumption, fuel consumption and in-cylinder combustion pressure, emission parameters viz. carbon monoxide, carbon dioxide, hydrocarbon, and nitrogen oxide, and lubricant degradation analyses were also considered to analyze the effects of piston scuffing fault on these parameters. The results provide a good correlation between vibration and acoustic signals, performance, and lubricant parameters to detect and diagnose the scuffing fault that appeared on the piston of the diesel engine.

Similar content being viewed by others

Abbreviations

- a :

-

Translation parameter

- b :

-

Dilation parameter

- \(b_{f}\) :

-

Damping factor for foundation block

- \(b_{e}\) :

-

Damping factor for frame and engine

- BTh:

-

Brake thermal efficiency (%)

- BP:

-

Brake power (kW)

- BSFC:

-

Brake specific fuel consumption (\(\frac{kg}{kWhr}\))

- \(\hbox {CO}_{2}\) :

-

Carbon dioxide (% )

- CO:

-

Carbon monoxide (%)

- dB :

-

Noise measured in decibel

- DAQ:

-

Data acquisition system

- FC:

-

Fuel consumption (\(\frac{kg}{hr}\))

- FFT:

-

Fast Fourier transform

- f :

-

Frequency (Hz)

- HC:

-

Hydrocarbon (ppm)

- k :

-

Frequency index (Hz)

- \(k_{f}\) :

-

Stiffness of the soil

- \(k_{e}\) :

-

Stiffness of bolt and elastic pad

- \(m_{f}\) :

-

Mass of frame and engine

- \(m_{e}\) :

-

Mass of the engine body

- \(\hbox {NO}_{x}\) :

-

Nitrogen oxide (ppm)

- p :

-

Sound pressure (Pa)

- \(p_{ref}\) :

-

Reference sound pressure (Pa)

- SPL :

-

Sound pressure level (dB)

- t :

-

Time (sec)

- W(a, b):

-

Wavelet coefficient

- x(t):

-

Time domain signal

- x(f):

-

Frequency domain signal

- \(x_{1}\) :

-

Displacement of the foundation block

- \(\dot{x_{1}}\) :

-

Velocity of the foundation block

- \(\ddot{x_{1}}\) :

-

Acceleration of the foundation block

- \(x_{2}\) :

-

Displacement of frame and engine

- \(\dot{x_{2}}\) :

-

Velocity of frame and engine

- \(\ddot{x_{2}}\) :

-

Acceleration of frame and engine

- \({\bar{x}}\) :

-

Mean of the samples

- \(\psi (t)\) :

-

Mother wavelet

- \(\psi ^{*}(t)\) :

-

Complex conjugate of the mother wavelet

References

Zweiri, Y.H., Whidborne, J.F., Seneviratne, L.D.: Dynamic simulation of a single-cylinder diesel engine including dynamometer modelling and friction. Proc. Inst. Mech. Eng. Part D 213(4), 391–402 (1999)

Meng, F.M., Hu, Y.Z., Wang, H., Zhang, Y.Y.: Analysis of the dynamic performances of a piston-crankshaft system considering oil-film forces reconstructed by a neural network. Proc. Instit. Mech. Eng. Part D 221(2), 171–80 (2007)

Singh, O.P., Umbarkar, Y., Sreenivasulu, T., Vetrivendan, E., Kannan, M., Babu, Y.R.: Piston seizure investigation: experiments, modeling and future challenges. Eng. Fail. Anal. 28, 302–10 (2013)

Moosavian, A., Najafi, G., Ghobadian, B., Mirsalim, M., Jafari, S.M., Sharghi, P.: Piston scuffing fault and its identification in an IC engine by vibration analysis. Appl. Acoust. 102, 40–8 (2016)

Moosavian, A., Najafi, G., Ghobadian, B., Mirsalim, M.: The effect of piston scratching fault on the vibration behavior of an IC engine. Appl. Acoust. 126, 91–100 (2017)

Jena, D.P., Panigrahi, S.N.: Motor bike piston-bore fault identification from engine noise signature analysis. Appl. Acoust. 76, 35–47 (2014)

Wakatsuki, Y., Watanabe, K., Yamamoto, T.: T-MAS.: the detector of scuffing before excessive wear. Mar. Eng. 41(6), 901–906 (2006)

Chiatti, G., Chiavola, O., Palmieri, F.: Vibration and acoustic characteristics of a city-car engine fueled with biodiesel blends. Appl. Energy 185, 664–70 (2017)

Barelli, L., Bidini, G., Buratti, C., Mariani, R.: Diagnosis of internal combustion engine through vibration and acoustic pressure non-intrusive measurements. Appl. Therm. Eng. 29(8–9), 1707–13 (2009)

Li, W., Gu, F., Ball, A.D., Leung, A.Y., Phipps, C.E.: A study of the noise from diesel engines using the independent component analysis. Mech. Syst. Signal Process. 15(6), 1165–84 (2001)

JunHong, Z., Bing, H.: Analysis of engine front noise using sound intensity techniques. Mech. Syst. Signal Process. 19(1), 213–21 (2005)

Çelebi, K., Uludamar, E., Özcanlı, M.: Evaluation of fuel consumption and vibration characteristic of a compression ignition engine fuelled with high viscosity biodiesel and hydrogen addition. Int. J. Hydrogen Energy 42(36), 23379–88 (2017)

Uludamar, E., Yıldızhan, Ş., Aydın, K., Özcanlı, M.: Vibration, noise and exhaust emissions analyses of an unmodified compression ignition engine fuelled with low sulphur diesel and biodiesel blends with hydrogen addition. Int. J. Hydrogen Energy 41(26), 11481–90 (2016)

Taghizadeh-Alisaraei, A., Ghobadian, B., Tavakoli-Hashjin, T., Mohtasebi, S.S., Rezaei-asl, A., Azadbakht, M.: Characterization of engine’s combustion-vibration using diesel and biodiesel fuel blends by time-frequency methods: a case study. Renew. Energy 95, 422–32 (2016)

Wang, X., Liu, C., Bi, F., Bi, X., Shao, K.: Fault diagnosis of diesel engine based on adaptive wavelet packets and EEMD-fractal dimension. Mech. Syst. Signal Process. 41(1–2), 581–97 (2013)

Li, W., Parkin, R.M., Coy, J., Gu, F.: Acoustic based condition monitoring of a diesel engine using self-organising map networks. Appl. Acoust. 63(7), 699–711 (2002)

Wu, J.D., Chen, J.C.: Continuous wavelet transform technique for fault signal diagnosis of internal combustion engines. NDT E Int. 39(4), 304–11 (2006)

Wu, J.D., Liu, C.H.: An expert system for fault diagnosis in internal combustion engines using wavelet packet transform and neural network. Expert Syst. Appl. 36(3), 4278–86 (2009)

Sharma, A., Sugumaran, V., Devasenapati, S.B.: Misfire detection in an IC engine using vibration signal and decision tree algorithms. Measurement 50, 370–80 (2014)

Taghizadeh-Alisaraei, A., Mahdavian, A.: Fault detection of injectors in diesel engines using vibration time-frequency analysis. Appl. Acoust. 143, 48–58 (2019)

Ayati, M., Shirazi, F.A., Ansari-Rad, S., Zabihihesari, A.: Classification-based fuel injection fault detection of a trainset diesel engine using vibration signature analysis. J. Dyn. Syst. Meas. Control 142(5), 051003 (2020)

Yildirim, Ş., Erkaya, S., Eski, İ., Uzmay, İ.: Noise and vibration analysis of car engines using proposed neural network. J. Vib. Control 15(1), 133–56 (2009)

Albarbar, A., Gu, F., Ball, A.D.: Diesel engine fuel injection monitoring using acoustic measurements and independent component analysis. Measurement 43(10), 1376–86 (2010)

Wu, J.D., Chuang, C.Q.: Fault diagnosis of internal combustion engines using visual dot patterns of acoustic and vibration signals. NDT E Int. 38(8), 605–14 (2005)

Figlus, T., Liščák, Š., Wilk, A., Łazarz, B.: Condition monitoring of engine timing system by using wavelet packet decomposition of a acoustic signal. J. Mech. Sci. Technol. 28(5), 1663–71 (2014)

Macián, V., Tormos, B., Gómez, Y.A., Salavert, J.M.: Proposal of an FTIR methodology to monitor oxidation level in used engine oils: effects of thermal degradation and fuel dilution. Tribol. Trans. 55(6), 872–82 (2012)

Zzeyani, S., Mikou, M., Naja, J., Elachhab, A.: Spectroscopic analysis of synthetic lubricating oil. Tribol. Int. 114, 27–32 (2017)

De Rivas, B.L., Vivancos, J.L., Ordieres-Meré, J., Capuz-Rizo, S.F.: Determination of the total acid number (TAN) of used mineral oils in aviation engines by FTIR using regression models. Chemometrics Intell. Lab. Syst. 160, 32–9 (2017)

Jenkins, S.H.: Analysis and treatment of diesel-engine noise. J. Sound Vib. 43(2), 293–304 (1975)

Taghizadeh-Alisaraei, A., Rezaei-Asl, A.: The effect of added ethanol to diesel fuel on performance, vibration, combustion and knocking of a CI engine. Fuel 185, 718–33 (2016)

Albarbar, A., Gu, F., Ball, A.D., Starr, A.: Acoustic monitoring of engine fuel injection based on adaptive filtering techniques. Appl. Acoust. 71(12), 1132–41 (2010)

Ramteke, S.M., Chelladurai, H., Amarnath, M.: Diagnosis of liner scuffing fault of a diesel engine via vibration and acoustic emission analysis. J. Vib. Eng. Technol. 1-9 (2019)

Dyson, A.: Scuffing-a review. Tribol. Int. 8(2), 77–87 (1975)

Becker, E.P., Ludema, K.C.: A qualitative empirical model of cylinder bore wear. Wear 225, 387–404 (1999)

Obiols, J.: Lubricant oxidation monitoring using FTIR analysis-application to the development of a laboratory bulk oxidation test and to in-service oil evaluation. SAE Trans. 1903–1914 (2003)

Chen, C.I., Hsu, S.M.: A chemical kinetics model to predict lubricant performance in a diesel engine. Part I: simulation methodology. Tribol. Lett. 14(2), 83–90 (2003)

Ramteke, S., Chelladurai, H.: Examining the role of hexagonal boron nitride nanoparticles as an additive in the lubricating oil and studying its application. Proc. Inst. Mech. Eng. Part N 234(1–2), 19–36 (2020)

Moosavian, A., Khazaee, M., Najafi, G., Kettner, M., Mamat, R.: Spark plug fault recognition based on sensor fusion and classifier combination using Dempster-Shafer evidence theory. Appl. Acoust. 93, 120–9 (2015)

Khazaee, M., Ahmadi, H., Omid, M., Banakar, A., Moosavian, A.: Feature-level fusion based on wavelet transform and artificial neural network for fault diagnosis of planetary gearbox using acoustic and vibration signals. Insight-Non-Destr. Test. Cond. Monit. 55(6), 323–30 (2013)

Amarnath, M., Sujatha, C., Swarnamani, S.: Gear fault assessment based on continuous wavelet transforms. Adv. Vib. Eng. 12(1), 33–47 (2013)

Nikolaou, N.G., Antoniadis, I.A.: Rolling element bearing fault diagnosis using wavelet packets. Ndt E Int. 35(3), 197–205 (2002)

Zheng, H., Li, Z., Chen, X.: Gear fault diagnosis based on continuous wavelet transform. Mech. Syst. Signal Process. 16(2–3), 447–57 (2002)

Taghizadeh-Alisaraei, A., Ghobadian, B., Tavakoli-Hashjin, T., Mohtasebi, S.S.: Vibration analysis of a diesel engine using biodiesel and petrodiesel fuel blends. Fuel 102, 414–22 (2012)

Neville, A., Morina, A., Haque, T., Voong, M.: Compatibility between tribological surfaces and lubricant additives—how friction and wear reduction can be controlled by surface/lube synergies. Tribol. Int. 40(10–12), 1680–1695 (2007)

van de Voort, F.R., Ghetler, A., García-González, D.L., Li, Y.D.: Perspectives on quantitative mid-FTIR spectroscopy in relation to edible oil and lubricant analysis: evolution and integration of analytical methodologies. Food Anal. Methods 1(3), 153–63 (2008)

Acknowledgements

The authors would like to thank St. Aloysius Institute of Technology, Jabalpur for providing the facility for FTIR test facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramteke, S.M., Chelladurai, H. & Amarnath, M. Effects of Piston Scuffing Fault on the Performance and Vibro-Acoustic Characteristics of a Diesel Engine: An Experimental Study. J Nondestruct Eval 40, 81 (2021). https://doi.org/10.1007/s10921-021-00811-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-021-00811-8