Abstract

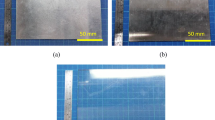

Thick (>50 μm) piezoelectric films have been deposited directly on top of steel and aluminum substrates as integrated ultrasonic transducer (IUT) receivers to detect laser generated ultrasound. The film fabrication is based on a sol-gel spray technique. In this study IUTs intrinsically acting as bulk longitudinal wave receivers use various mode conversion approaches and serve as longitudinal, shear, symmetric, anti-symmetric and shear horizontal plate wave receivers. Different laser generation conditions such as point and line sources of different sizes are also applied to investigate the capabilities of IUT receivers. Ultrasonic measurements on metal substrates with planar and curved surfaces at temperature up to 400°C using laser generated and IUT ultrasound receiver are demonstrated.

Similar content being viewed by others

References

White, R.M.: Generation of elastic waves by transient surface heating. J. Appl. Phys. 34, 3559–3567 (1963)

Scruby, C.B., Dewhurst, R.J., Hutchins, D.A., Palmer, S.B.: Laser generation of ultrasound in metals. In: Sharpe, R.S. (ed.) Res. Techniques in Nondestructrive Testing, vol. 5, pp. 281–327. Academic Press, San Diego (1982)

Hutchins, D.A.: Ultrasonic generation by pulsed lasers. In: Mason, W.P., Thurston, R.N. (eds.) Phys. Acoustics, vol. 18, pp. 21–123. Academic Press, San Diego (1988)

Adler, R., Korpel, A., Desmares, P.: An instrument for making surface waves visible. IEEE Trans. Sonics Ultrason. 15, 157–161 (1968)

Kessler, L.W., Palermo, P.R., Korpel, A.: Recent developments with the scanning laser acoustic microscope. In: Green, P.S. (ed.) Acoustic Holography, pp. 15–23. Plenum Press, New York (1974)

Monchalin, J.P.: Optical detection of ultrasound. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 33, 485–499 (1986)

Wagner, J.W.: Optical detection of ultrasound. In: Mason, W.P., Thurston, R.N. (eds.) Phys. Acoustics, vol. 19, pp. 201–264. Academic Press, San Diego (1990)

Ing, R.K., Monchalin, J.P.: Broadband optical detection of ultrasound by two-wave mixing in a photorefractive crystal. Appl. Phys. Lett. 59, 3233–3235 (1991)

Birks, A.S., Green, R.E. Jr., McIntire P.: Nondestructive Testing Handbook, 2nd edn. Ultrasonic Testing, ASNT, vol. 7. (1991)

Gandhi, M.V., Thompson, B.S.: Smart Materials and Structures. Chapman & Hall, London (1992)

Lee, J.-R., Takatsubo, J., Toyama, N.: Disbond monitoring at wing stringer tip based on built-in ultrasonic transducers and a pulsed laser. Smart Mater. Struct. 16(4), 1025–1035 (2007)

Lee, J.-R., Takatsubo, J., Toyama, N., Kang, D.-H.: Health monitoring of complex curved structures using an ultrasonic wavefield propagation imaging system. Meas. Sci. Technol. 18(12), 3816–3824 (2007)

Yashiro, S., Takatsubo, J., Miyauchi, H., Toyama, N.: A novel technique for visualizing ultrasonic waves in general solid media by pulsed laser scan. NDT E Int. 41(2), 137–144 (2008)

Chia, C.C., Lee, J.-R., Shin, H.-J.: Hot target inspection using a welded fibre acoustic wave piezoelectric sensor and a laser-ultrasonic mirror scanner. Meas. Sci. Technol. 20(12), 127003_1-8 (2009)

Barrow, D.A., Petroff, T.E., Tandon, R.P., Sayer, M.: Characterization of thick lead zirconate titanate films fabricated using a new sol gel based process. J. Appl. Phys. 81(2), 876–881 (1997)

Kobayashi, M., Jen, C.-K.: Piezoelectric thick bismuth titanate/PZT composite film transducers for smart NDE of metals. Smart Mater. Struct. 13(4), 951–956 (2004)

Kobayashi, M., Jen, C.-K., Bussiere, J.F., Wu, K.-T.: High temperature integrated and flexible ultrasonic transducers for non-destructive testing. NDT E Int. 42(2), 157–161 (2009)

Wu, K.-T., Kobayashi, M., Jen, C.-K.: Integrated high temperature piezoelectric plate acoustic wave transducers using mode conversion. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 56, 1218–1224 (2009)

Jen, C.-K., Ono, Y., Kobayashi, M.: High temperature integrated ultrasonic shear wave probes. Appl. Phys. Lett. 89, 183506_1-3 (2006)

Jen, C.-K., Wu, K.-T., Kobayashi, M., Kuo, J.-H., Mrad, N.: Integrated surface and plate acoustic wave sensors for health monitoring. Proc. SPIE Symp. Smart Struct. Mater. 6532, 6532061-8 (2007)

Walker, W.F., Trahey, G.E.: A fundamental limit on delay estimation using partially correlated speckle signals. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 42(2), 301–308 (1995)

Aussel, J.-D., Monchalin, J.-P.: Precision laser-ultrasonic velocity measurement and elastic constant determination. Ultrasonics 27(3), 165–177 (1989)

Kazys, R., Voleisis, A., Voleisiene, B.: High temperature ultrasonic transducers—review. Ultragarsas (Ultrasound) 63(2), 7–17 (2008)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, KT., Jen, CK., Kobayashi, M. et al. Integrated Piezoelectric Ultrasonic Receivers for Laser Ultrasound in Non-destructive Testing of Metals. J Nondestruct Eval 30, 1–8 (2011). https://doi.org/10.1007/s10921-010-0084-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-010-0084-2