Abstract

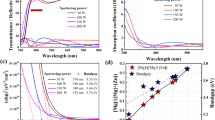

Heterojunction interfacial engineering plays a crucial role for the CIGS efficiency promotion. Chemical bath deposition (CBD) prepared CdS is the most preferred buffer for CIGS solar cells. Hence, manipulating the CdS properties to further boost heterojunction quality is a promising way to achieve higher efficiency CIGS solar cells. In this work, CdS buffer layer was modified by (NH4)2S (AS-treatment) solutions. The results showed that after AS treatment, the impurities on CdS film were cleaned and the S vacancy was passivated. Moreover, it introduced larger build-in electric field, wider depletion width and less interface defect densities, which contributed to suppressed interface recombination and more efficient carrier separation and collection. Consequently, the CIGS solar cell based on AS-treatment achieved champion efficiency of 15.52%, with improved VOC of 643 mV and FF of 73.3%.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article and its supplementary information files. It will be made available on request.

References

J. Ramanujam, U.P. Singh, Copper indium gallium selenide based solar cells-a review. Energy Environ. Sci. 10, 1306–1319 (2017). https://doi.org/10.1039/C7EE00826K

M. Nakamura, K. Yamaguchi, Y. Kimoto, Y. Yasaki, T. Kato, H. Sugimoto, Cd-free Cu(in,Ga)(Se,S)2 thin-film solar cell with record efficiency of 23.35%. IEEE J. Photovolt. 9, 1863–1867 (2019). https://doi.org/10.1109/JPHOTOV.2019.2937218

Y.H. Chang, R. Carron, M. Ochoa, C. Bozal Ginesta, A.N. Tiwari, J.R. Durrant, L. Steier, Insights from transient absorption spectroscopy into electron dynamics along the Ga-gradient in Cu(in,Ga)Se2 solar cells. Adv. Energy Mater. 11, 2003446 (2021). https://doi.org/10.1002/aenm.202003446

Y.H. Wang, L.H. Tu, Y.L. Chang, S.K. Lin, T.Y. Lin, C.H. Lai, Surface sulfurization of Cu(in,Ga)Se2 solar cells by cosputtering In2S3 in the one-step sputtering process. ACS Appl. Energy Mater. 4, 11555–11563 (2021). https://doi.org/10.1021/acsaem.1c02299

T. Maeda, A. Kawabata, T. Wada, First-principles study on alkali-metal effect of Li, na, and K in Cu2ZnSnS4 and Cu2ZnSnSe4. Phys. Status Solidi A 12, 631–637 (2015). https://doi.org/10.1002/pssc.201400345

A. Chirila, P. Reinhard, F. Pianezzi, P. Bloesch, A.R. Uhl, C. Fella, L. Kranz, D. Keller, C. Gretener, H. Hagendorfer, D. Jaeger, R. Erni, S. Nishiwaki, S. Buecheler, A.N. Tiwari, Potassium-induced surface modification of Cu(in,Ga)Se2 thin films for high-efficiency solar cells. Nat. Mater. 12, 1107–1111 (2013). https://doi.org/10.1038/nmat3789

T.Y. Lin, I. Khatri, J. Matsuura, K. Shudo, W.C. Huang, M. Sugiyama, C.H. Lai, T. Nakada, Alkali-induced grain boundary reconstruction on Cu(in,Ga)Se2 thin film solar cells using cesium fluoride post deposition treatment. Nano Energy. 68, 104299 (2020). https://doi.org/10.1016/j.nanoen.2019.104299

S. Siebentritt, E. Avancini, M. Bär, J. Bombsch, E. Bourgeois, S. Buecheler, R. Carron, C. Castro, S. Duguay, R. Félix, E. Handick, D. Hariskos, V. Havu, P. Jackson, H.P. Komsa, T. Kunze, M. Malitckaya, R. Menozzi, M. Nesladek, N. Nicoara, M. Puska, M. Raghuwanshi, P. Pareige, S. Sadewasser, G. Sozzi, A.N. Tiwari, S. Ueda, A. Vilalta Clemente, T.P. Weiss, F. Werner, R.G. Wilks, W. Witte, M.H. Wolter, Heavy alkali treatment of Cu(in,Ga)Se2 solar cells: surface versus bulk effects. Adv. Energy Mater. 10, 1903752 (2020). https://doi.org/10.1002/aenm.201903752

D. Hariskos, S. Spiering, M. Powalla, Buffer layers in Cu(in,Ga)Se2 solar cells and modules. Thin Solid Films. 480–481, 99–109 (2005). https://doi.org/10.1016/j.tsf.2004.11.118

Z. Xu, Q. Gao, C. Cui, S. Yuan, D. Kou, Z. Zhou, W. Zhou, Y. Meng, Y. Qi, M. Ishaq, U.A. Shah, S. Wu, Gradient conduction band energy engineering driven high-efficiency solution-processed Cu2ZnSn(S,Se)4/ZnxCd1–xS solar cells. Adv. Funct. Mater. 33, 2009187 (2022). https://doi.org/10.1002/adfm.202209187

Q. Chang, S. Yuan, J. Fu, Q. Gao, Y. Zhao, Z. Xu, D. Kou, Z. Zhou, W. Zhou, S. Wu, Interface engineering for high-efficiency solution-processed Cu(in,Ga)(S,Se)2 solar cells via a novel indium-doped CdS strategy. ACS Appl. Mater. Interfaces. 14, 5149–5158 (2022). https://doi.org/10.1021/acsami.1c12587

J.K. Larsen, F. Larsson, T. Törndahl, N. Saini, L. Riekehr, Y. Ren, A. Biswal, D. Hauschild, L. Weinhardt, C. Heske, Platzer-Björkman, Cadmium free Cu2ZnSnS4 solar cells with 9.7% efficiency. Adv. Energy Mater. 9, 1900439 (2019). https://doi.org/10.1002/aenm.201900439

H. Khallaf, I.O. Oladeji, G. Chai, L. Chow, Characterization of CdS thin films grown by chemical bath deposition using four different cadmium sources. Thin Solid Films. 516, 7306–7312 (2008). https://doi.org/10.1016/j.tsf.2008.01.004

D.S. Kim, G.S. Park, B. Kim, S. Bae, S.Y. Park, H.S. Oh, U. Lee, D.H. Ko, J. Kim, B.K. Min, Achieving over 15% efficiency in solution-processed Cu(in,Ga)(S,Se)2 thin-film solar cells via a heterogeneous-formation-induced benign p-n junction interface. ACS Appl. Mater. Interfaces. 13, 13289–13300 (2021). https://doi.org/10.1021/acsami.1c00781

D.A.R. Barkhouse, R. Haight, N. Sakai, H. Hiroi, H. Sugimoto, D.B. Mitzi, Cd-free buffer layer materials on Cu2ZnSn(SxSe1–x)4: band alignments with ZnO, ZnS, and In2S3. Appl. Phys. Lett. 100, 193904 (2012). https://doi.org/10.1063/1.4714737

S. Lee, E.S. Lee, T.Y. Kim, J.S. Cho, Y.J. Eo, J.H. Yun, A. Cho, Effect of annealing treatment on CdS/CIGS thin film solar cells depending on different CdS deposition temperatures. Sol. Energy Mater. Sol. Cells. 141, 299–308 (2015). https://doi.org/10.1016/j.solmat.2015.05.052

C. Ma, X. Lu, B. Xu, F. Zhao, X. An, B. Li, F. Yue, J. Jiang, Y. Chen, L. Sun, J. Chu, Effect of CZTS/CdS interfaces deposited with sputtering and CBD methods on voc deficit and efficiency of CZTS solar cells. J. Alloys Compd. 817, 153329 (2020). https://doi.org/10.1016/j.jallcom.2019.153329

A. Cho, I. Jeong, S. Song, D. Shin, S. Lee, K. Kim, J.H. Yun, J.S. Cho, J.H. Park, Mechanism based approach of CdS/Cu(in,Ga)Se2(CIGS) interfaces for CIGS solar cells through deposition in different stages of continuous chemical bath deposition reaction: key to achieving high photovoltaic performance. Solar RRL. 5, 2100485 (2021). https://doi.org/10.1002/solr.202100485

W. Wang, Z. Cao, L. Wu, G. Chen, J. Ao, J. Luo, Y. Zhang, Interface etching leads to the inversion of the conduction band offset between the CdS/Sb2Se3 heterojunction and high-efficient Sb2Se3 solar cells. ACS Appl. Energy Mater. 5, 2531–2541 (2022). https://doi.org/10.1021/acsaem.1c04078

S. Yuan, X. Wang, Y. Zhao, Q. Chang, Z. Xu, J. Kong, S. Wu, Solution processed Cu(in,Ga)(S,Se)2 solar cells with 15.25% efficiency by surface sulfurization. ACS Appl. Energy Mater. 3, 6785–6792 (2020). https://doi.org/10.1021/acsaem.0c00917

S. Wang, Z. Shen, J. Wu, L. Wu, H. Li, G. Liang, J. Ao, H. Wang, Y. Zhang, Nanoscale surface electrical properties tailored by room-temperature sulfurization for high-efficient CZTSe solar cells. Adv. Mater. Interfaces. 7, 2000564 (2020). https://doi.org/10.1002/admi.202000564

Y. Wang, X. Xu, W. Lu, Y. Huo, L. Bian, A sulfur vacancy rich CdS based composite photocatalyst with g-C3N4 as a matrix derived from a Cd-S cluster assembled supramolecular network for H2 production and VOC removal. Dalton Trans. 47, 4219–4227 (2018). https://doi.org/10.1039/c7dt04912a

S. Hu, Y. Li, F. Li, Z. Fan, H. Ma, W. Li, X. Kang, Construction of g-C3N4/Zn0.11Sn0.12Cd0.88S1.12 hybrid heterojunction catalyst with outstanding nitrogen photofixation performance induced by sulfur vacancies. ACS Sustainable Chem. Eng. 4, 2269–2278 (2016). https://doi.org/10.1021/acssuschemeng.5b01742

Z.K. Heiba, M.B. Mohamed, N.G. Imam, Fine-tune optical absorption and light emitting behavior of the CdS/PVA hybridized film nanocomposite. J. Mol. Struct. 1136, 321–329 (2017). https://doi.org/10.1016/j.molstruc.2017.02.020

L. Teng, J. Tong, G. Wang, L. Wang, L. Chen, S. Wang, Y. Wang, D. Pan, X. Zhang, Y. Liu, Novel two-step CdS deposition strategy to improve the performance of Cu2ZnSn(S,Se)4 solar cell. J. Energy Chem. 42, 77–82 (2020). https://doi.org/10.1016/j.jechem.2019.06.011

Y. Zhao, S. Yuan, Q. Chang, Z. Zhou, D. Kou, W. Zhou, Y. Qi, S. Wu, Controllable formation of ordered vacancy compound for high efficiency solution processed Cu(in,Ga)Se2 solar cells. Adv. Funct. Mater. 31, 2007928 (2020). https://doi.org/10.1002/adfm.202007928

Q. Gao, S. Yuan, Z. Zhou, D. Kou, W. Zhou, Y. Meng, Y. Qi, L. Han, S. Wu, Over 16% efficient solution-processed Cu(in,Ga)Se2 solar cells via incorporation of copper-rich precursor film. Small. 18, 2203443 (2022). https://doi.org/10.1002/smll.202203443

A. Guchhait, Z. Su, Y.F. Tay, S. Shukla, W. Li, S.W. Leow, J.M.R. Tan, S. Lie, O. Gunawan, L.H. Wong, Enhancement of open-circuit voltage of solution-processed Cu2ZnSnS4 solar cells with 7.2% efficiency by incorporation of silver. ACS Energy Lett. 1, 1256–1261 (2016). https://doi.org/10.1021/acsenergylett.6b00509

C.J. Hages, M.J. Koeper, R. Agrawal, Optoelectronic and material properties of nanocrystal-based CZTSe absorbers with Ag-alloying. Sol. Energy Mater. Sol. Cells. 145, 342–348 (2016). https://doi.org/10.1016/j.solmat.2015.10.039

Y. Zhao, S. Yuan, D. Kou, Z. Zhou, X. Wang, H. Xiao, Y. Deng, C. Cui, Q. Chang, S. Wu, High efficiency CIGS solar cells by bulk defect passivation through Ag substituting strategy. ACS Appl. Mater. Interfaces. 12, 12717–12726 (2020). https://doi.org/10.1021/acsami.9b21354

Z. Su, G. Liang, P. Fan, J. Luo, Z. Zheng, Z. Xie, W. Wang, S. Chen, J. Hu, Y. Wei, C. Yan, J. Huang, X. Hao, F. Liu, Device postannealing enabling over 12% efficient solution-processed Cu2ZnSnS4 solar cells with Cd2+ substitution. Adv. Mater. 32, 2000121 (2020). https://doi.org/10.1002/adma.202000121

S. Kim, M.S. Mina, J. Lee, J. Kim, Sulfur-alloying effects on Cu(in,Ga)(S,Se)2 solar cell fabricated using aqueous spray pyrolysis. ACS Appl. Mater. Interfaces. 11, 45702–45708 (2019). https://doi.org/10.1021/acsami.9b16192

Y.R. Lin, V. Tunuguntla, S.Y. Wei, W.C. Chen, D. Wong, C.H. Lai, L.K. Liu, L.C. Chen, K.H. Chen, Bifacial sodium-incorporated treatments: tailoring deep traps and enhancing carrier transport properties in Cu2ZnSnS4 solar cells. Nano Energy. 16, 438–445 (2015). https://doi.org/10.1016/j.nanoen.2015.07.022

G. Wang, W. Zhao, Y. Cui, Q. Tian, S. Gao, L. Huang, D. Pan, Fabrication of a Cu2ZnSn(S,Se)4 photovoltaic device by a low-toxicity ethanol solution process. ACS Appl. Mater. Interfaces. 5, 10042–10047 (2013). https://doi.org/10.1021/am402558a

Y.H. Zhao, Q.Q. Gao, S.J. Yuan, Q.Q. Chang, T. Liang, Z.H. Su, H.L. Ma, S. Chen, G.X. Liang, P. Fan, X.H. Zhang, S.X. Wu, Defects passivation and crystal growth promotion by solution-processed K doping strategy toward 16.02% efficiency Cu(in,Ga)(S,Se)2 solar cells. Chem. Eng. J. 436, 135008 (2022). https://doi.org/10.1016/j.cej.2022.135008

B. Duan, L. Guo, Q. Yu, J. Shi, H. Wu, Y. Luo, D. Li, S. Wu, Z. Zheng, Q. Meng, Highly efficient solution-processed CZTSSe solar cells based on a convenient sodium-incorporated post-treatment method. J. Energy Chem. 40, 196–203 (2020). https://doi.org/10.1016/j.jechem.2019.03.029

Funding

This study is supported by scientific Research Foundation from North China University of Water Resources and Electric Power (Grant No. 4001/40510), the National Natural. Science Foundation of China (Grant Nos. 51802081, 62074052, 61974173, 62104061 and 52072327).

Author information

Authors and Affiliations

Contributions

The manuscript was written through contribution of all authors. All authors have approval to the final version of the manuscript. XW: experiments, characterization, writing—original draft. YL: discussion, EQE measurement. QG: discussion, EIS measurement. JK: data analyses, discussion and review. SY: supervision, discussion, writing—review & editing. SW: discussion and data analyses.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Li, Y., Gao, Q. et al. (NH4)2S-induced improvement of CdS buffer layer for 15.52% efficiency solution-processed CIGS solar cell. J Mater Sci: Mater Electron 34, 1680 (2023). https://doi.org/10.1007/s10854-023-11097-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-023-11097-z