Abstract

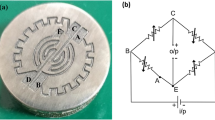

The performance of vacuum insulation panels (VIPs) is greatly determined by their internal vacuum, which is difficult to maintain constant for a long period of time, thus leading to their premature aging. This degradation is mainly caused by the underlying gas and moisture permeation under an extreme environment or from the residual material left inside during the manufacturing process. Hence, the development of smart pressure sensors capable of identifying minute fluctuations in the internal pressure at an initial stage is currently highly desirable in the industry. In the present study, the electrospinning technique was used for the fabrication of poly(vinylidene fluoride-trifluoroethylene) P(VDF-TrFE) and graphene-oxide-modified poly(vinylidene fluoride-trifluoroethylene) GO-P(VDF-TrFE) fiber membranes for piezoelectric pressure-sensing applications. The conventional interdigitated electrode was successfully deposited on the fibrous structure with high continuity in the fingers. The thermal stability and compatibility of the prepared structures were ascertained by performing the thermal characterization. The developed devices revealed high electric output when exposed to the pressure. The GO-P(VDF-TrFE) smart fiber-based device offered admirable response time (0.282 s) and high linearity of R2 = 0.99294, respectively. Our findings will lay a foundation for the establishment of future wireless smart structures capable of detecting small internal pressure (≤ 10 Pa) in many devices such as VIPs and other products even after their installation in building structures.

Similar content being viewed by others

References

X. Qing, W. Li, Y. Wang, H. Sun, Piezoelectric transducer-based structural health monitoring for aircraft applications. Sensors 19(3), 545 (2019). https://doi.org/10.3390/s19030545

V. Giurgiutiu, Structural health monitoring (SHM) of aerospace composites, Polymer Composites in the Aerospace Industry (Elsevier, Amsterdam, 2020), pp. 491–558. https://doi.org/10.1016/B978-0-08-102679-3.00017-4

E.D. Gregory, W.C. Schneck III, C.A. Leckey, P. Swindell, Simulation assisted guided wave structural health monitoring of aerospace structures, in AIP Conference Proceedings, 2019, vol. 2102, no. 1, pp. 130006: AIP Publishing LLC. (2019). https://doi.org/10.1063/1.5099856

V. Rahul, S. Alokita, K. Jayakrishna, V.R. Kar, M. Rajesh, S. Thirumalini, M. Manikandan, Structural health monitoring of aerospace composites, Structural Health Monitoring of Biocomposites Fibre-Reinforced Composites and Hybrid Composites (Woodhead Publishing, Cambridge, 2019), pp. 33–52. https://doi.org/10.1016/B978-0-08-102291-7.00003-4

Y. Wang, L. Qiu, Y. Luo, R. Ding, "A stretchable and large-scale guided wave sensor network for aircraft smart skin of structural health monitoring, Structural Health Monitoring (Sage Publications, London, 2019), pp. 1–16. https://doi.org/10.1177/1475921719850641

W.S. Na, J. Baek, A review of the piezoelectric electromechanical impedance based structural health monitoring technique for engineering structures. Sensors 18(5), 1307 (2018). https://doi.org/10.3390/s18051307

G. Heo, B. Son, C. Kim, S. Jeon, J. Jeon, Development of a wireless unified-maintenance system for the structural health monitoring of civil structures. Sensors 18(5), 1485 (2018). https://doi.org/10.3390/s18051485

C.R. Farrar, K. Worden, An introduction to structural health monitoring. Philos. Trans. R. Soc. A 365(1851), 303–315 (2007). https://doi.org/10.1098/rsta.2006.1928

J.P. Lynch, An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A 365(1851), 345–372 (2007). https://doi.org/10.1098/rsta.2006.1932

B. Chapuis, Introduction to structural health monitoring, Sensors Algorithms and Applications for Structural Health Monitoring (Springer, Cham, 2018), pp. 1–11. https://doi.org/10.1007/978-3-319-69233-3_1

H.-P. Chen, Structural Health Monitoring of Large Civil Engineering Structures (Wiley, Hoboken, 2018)

H.-R. Shih, W.L. Walters, W. Zheng, J. Everett, Course modules on structural health monitoring with smart materials. J. Technol. Stud. 35(2), 65–73 (2009). https://doi.org/10.21061/jots.v35i2.a.7

D. Balageas, C.-P. Fritzen, A. Güemes, Structural Health Monitoring (Wiley, Hoboken, 2010)

H.U. Rehman, Experimental performance evaluation of solid concrete and dry insulation materials for passive buildings in hot and humid climatic conditions. Appl. Energy 185, 1585–1594 (2017). https://doi.org/10.1016/j.apenergy.2016.01.026

P.M. Congedo, C. Baglivo, G. Centonze, Walls comparative evaluation for the thermal performance improvement of low-rise residential buildings in warm Mediterranean climate. J. Build. Eng. 28, 101059 (2020). https://doi.org/10.1016/j.jobe.2019.101059

B.P. Jelle, Traditional, state-of-the-art and future thermal building insulation materials and solutions—properties, requirements and possibilities. Energy Build. 43(10), 2549–2563 (2011). https://doi.org/10.1016/j.enbuild.2011.05.015

E. Cuce, P.M. Cuce, C.J. Wood, S.B. Riffat, Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew. Sustain. Energy Rev. 34, 273–299 (2014). https://doi.org/10.1016/j.rser.2014.03.017

W. Villasmil, L.J. Fischer, J. Worlitschek, A review and evaluation of thermal insulation materials and methods for thermal energy storage systems. Renew. Sustain. Energy Rev. 103, 71–84 (2019). https://doi.org/10.1016/j.rser.2018.12.040

M. Alam, H. Singh, M.C. Limbachiya, Vacuum Insulation Panels (VIPs) for building construction industry—a review of the contemporary developments and future directions. Appl. Energy 88(11), 3592–3602 (2011). https://doi.org/10.1016/j.apenergy.2011.04.040

Z. Chen, Z.F. Chen, J.L. Qiu, T.Z. Xu, J.M. Zhou, Vacuum insulation panel for green building. Appl. Mech. Mater. 71, 607–611 (2011). https://doi.org/10.4028/www.scientific.net/AMM.71-78.607

C. Peng, J. Yang, Structure, mechanism, and application of vacuum insulation panels in Chinese buildings. Adv. Mater. Sci. Eng. 2016, 1–16 (2016). https://doi.org/10.1155/2016/1358072

L. Aditya, T.M.I. Mahlia, B. Rismanchi, H.M. Ng, M.H. Hasan, H.S.C. Metselaar, O. Muraza, H.B. Aditiy, A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 73, 1352–1365 (2017). https://doi.org/10.1016/j.rser.2017.02.034

M. Alam, H. Singh, S. Suresh, D. Redpath, Energy and economic analysis of Vacuum Insulation Panels (VIPs) used in non-domestic buildings. Appl. Energy 188, 1–8 (2017). https://doi.org/10.1016/j.apenergy.2016.11.115

S. Verma, H. Singh, Vacuum insulation panels for refrigerators. Int. J. Refrig. 112, 215–228 (2020). https://doi.org/10.1016/j.ijrefrig.2019.12.007

E. Wegger, B.P. Jelle, E. Sveipe, Aging effects on thermal properties and service life of vacuum insulation panels. J. Build. Phys. 35(2), 128–167 (2011). https://doi.org/10.1177/1744259111398635

X. Di, Y. Gao, C. Bao, S. Ma, Thermal insulation property and service life of vacuum insulation panels with glass fiber chopped strand as core materials. Energy Build. 73, 176–183 (2014). https://doi.org/10.1016/j.enbuild.2014.01.010

H. Simmler, S. Brunner, U. Heinemann, H. Schwab, K. Kumaran, P. Mukhopadhyaya, D. Quenard, H. Sallee, K. Noller, E. Kuecuekpinar-Niarchos, C. Stramm, M. Tenpierik, H. Cauberg, H, M. Erb, "IEA/ECBCS Annex 39: Vacuum Insulation Panels—Study on VIP-components and Panels for Service Life Prediction of VIP in Building Applications (Subtask A),", Switzerland, (2005), https://www.osti.gov/etdeweb/biblio/21131463. Accessed 23 Aug 2020

T. Sharma, S.-S. Je, B. Gill, J.X. Zhang, Patterning piezoelectric thin film PVDF–TrFE based pressure sensor for catheter application. Sens. Actuators A 177, 87–92 (2012). https://doi.org/10.1016/j.sna.2011.08.019

Y. Zang, F. Zhang, C.-A. Di, D. Zhu, Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2(2), 140–156 (2015). https://doi.org/10.1039/C4MH00147H

L. Persano, C. Dagdeviren, C. Maruccio, L. De Lorenzis, D. Pisignano, Cooperativity in the enhanced piezoelectric response of polymer nanowires. Adv. Mater. 26(45), 7574–7580 (2014). https://doi.org/10.1002/adma.201403169

A. Wang, M. Hu, L. Zhou, X. Qiang, Self-powered wearable pressure sensors with enhanced piezoelectric properties of aligned P(VDF-TrFE)/MWCNT composites for monitoring human physiological and muscle motion signs. Nanomaterials 8(12), 1021 (2018). https://doi.org/10.3390/nano8121021

Y. Jiang, L. Gong, X. Hu, Y. Zhao, H. Chen, L. Feng, D. Zhang, Aligned P (VDF-TrFE) nanofibers for enhanced piezoelectric directional strain sensing. Polymers 10(4), 364 (2018). https://doi.org/10.3390/polym10040364

B. Li, F. Zhang, S. Guan, J. Zheng, C. Xu, Wearable piezoelectric device assembled by one-step continuous electrospinning. J. Mater. Chem. C 4(29), 6988–6995 (2016). https://doi.org/10.1039/x0xx00000x

S. Thenmozhi, N. Dharmaraj, K. Kadirvelu, H.Y. Kim, Electrospun nanofibers: new generation materials for advanced applications. Mater. Sci. Eng., B 217, 36–48 (2017). https://doi.org/10.1016/j.mseb.2017.01.001

J.K.Y. Lee, N. Chen, S. Peng, L. Li, L. Tian, N. Thakor, S. Ramakrishna, Polymer-based composites by electrospinning: preparation & functionalization with nanocarbons. Prog. Polym. Sci. 86, 40–84 (2018). https://doi.org/10.1016/j.progpolymsci.2018.07.002

N.M. Aboamera, A. Mohamed, A. Salama, T. Osman, A. Khattab, Characterization and mechanical properties of electrospun cellulose acetate/graphene oxide composite nanofibers. Mech. Adv. Mater. Struct. 26(9), 765–769 (2019). https://doi.org/10.1080/15376494.2017.1410914

J. Zhao, Y. Yang, W. Yu, Q. Ma, X. Dong, X. Wang, J. Wang, G. Liu, Bi 2 MoO 6/RGO composite nanofibers: facile electrospinning fabrication, structure, and significantly improved photocatalytic water splitting activity. J. Mater. Sci.: Mater. Electron. 28(1), 543–552 (2017). https://doi.org/10.1007/s10854-016-5557-3

C. Brundha, R. Govindaraj, N. Santhosh, M. Senthil Pandian, P. Ramasamy, S. Karuppuchamy, Preparation of one dimensional titanium dioxide nanowires using electrospinning process for dye-sensitized solar cells. J. Mater. Sci.: Mater. Electron. 28(15), 11509–11514 (2017). https://doi.org/10.1007/s10854-017-6947-x

H. Yu, Y. Li, X. Lan, Z. Liang, Electrospinning preparation and luminescence properties of La2O3: Ce3+/Tb3+ nanofibers. J. Mater. Sci.: Mater. Electron. 28(12), 8832–8836 (2017). https://doi.org/10.1007/s10854-017-6611-5

N. Chamankar, R. Khajavi, A.A. Yousefi, A.S. Rashidi, F. Golestanifard, Comparing the piezo, pyro and dielectric properties of PZT particles synthesized by sol–gel and electrospinning methods. J. Mater. Sci.: Mater. Electron. 30(9), 8721–8735 (2019). https://doi.org/10.1007/s10854-019-01197-0

Q. Fatima, A.A. Haidry, Z. Yao, Y. He, Z. Li, L. Sun, L. Xie, The critical role of hydroxyl groups in water vapor sensing of graphene oxide. Nanoscale Adv. 1(4), 1319–1330 (2019). https://doi.org/10.1039/c8na00135a

Y.J. Hwang, S. Choi, H.S. Kim, Structural deformation of PVDF nanoweb due to electrospinning behavior affected by solvent ratio. e-Polymers 18(4), 339–345 (2018). https://doi.org/10.1515/epoly-2018-0037

D. Mao, B.E. Gnade, M.A. Quevedo-Lopez, Ferroelectric properties and polarization switching kinetic of poly (vinylidene fluoride-trifluoroethylene) copolymer, Ferroelectrics-Physical Effects (InTech, Rijeka, 2011), pp. 78–100

N. Weber, Y.-S. Lee, S. Shanmugasundaram, M. Jaffe, T.L. Arinzeh, Characterization and in vitro cytocompatibility of piezoelectric electrospun scaffolds. Acta Biomater. 6(9), 3550–3556 (2010). https://doi.org/10.1016/j.actbio.2010.03.035

C. Ribeiro, V. Sencadas, J.L.G. Ribelles, S. Lanceros-Méndez, Influence of processing conditions on polymorphism and nanofiber morphology of electroactive poly (vinylidene fluoride) electrospun membranes. Soft Mater. 8(3), 274–287 (2010). https://doi.org/10.1080/1539445X.2010.495630

X. Ren, Nanomanufacturing and Analysis of Novel Continuous Ferroelectric PVDF and P (VDF-TrFE) Nanofibers (The University of Nebraska-Lincoln, Lincoln, 2007)

R. Bhunia, S. Gupta, B. Fatma, Prateek, R.K. Gupta, A. Garg, Milli-Watt power harvesting from dual triboelectric and piezoelectric effects of multifunctional green and robust reduced graphene oxide/P (VDF-TrFE) composite flexible films. ACS Appl. Mater. Interfaces 11(41), 38177–38189 (2019). https://doi.org/10.1021/acsami.9b13360

Acknowledgements

This work was carried out under a joint project between Nanjing University of Aeronautics and Astronautics (NUAA), China, and the University of Victoria (UoV), Canada. The project (Grant No. SBZ2019000139) was titled as "Joint Research of Nano modified Ultra-fine Glass Fiber Core with Indulgent Pressure."

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known conflicts of interests that could appear to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahzad, A., Chen, Z., Haidary, A.A. et al. Piezoelectric pressure sensors based on GO-modified P(VDF-TrFE) fibers for vacuum applications. J Mater Sci: Mater Electron 31, 18627–18639 (2020). https://doi.org/10.1007/s10854-020-04405-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-020-04405-4