Abstract

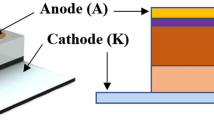

In order to produce an indium-doped ZnO/CuO thin film diode using spray pyrolysis, a high-quality indium-doped ZnO thin film with the resistivity of 5.65 × 10−3 Ω cm and the average transparency of 90% (400–800 nm) was first spray-deposited onto a glass substrate. Then, a p-type CuO layer was spray-deposited on top of the indium-doped ZnO film and the deposition temperature was varied from 300 to 400 °C with 25 °C steps (named IC1–IC5). The structural, morphological, and optical properties of both indium-doped ZnO and CuO thin films were studied. In addition, the current–voltage characteristics of the resulting IZO/CuO samples were recorded at room temperature and dark condition from − 1.5 to 1.5 V. Apart from IC1 and IC5 samples, the IV characteristics of the other samples showed an exponential attitude which confirmed the formation of heterojunction diodes. Diode parameters were calculated for the aforementioned heterojunction using thermionic emission theory. It was found that as the deposition temperature of the CuO layer increases, the barrier height remains almost unchanged, the rectifying ratio increases, and the series resistance reduces drastically. The estimated ideality factors were significantly larger than 1, which is indicative of the non-ideal attitude of the resulting diodes.

Similar content being viewed by others

References

Q. Zhang, K. Zhang, D. Xu, G. Yang, H. Huang, F. Nie, C. Liu, S. Yang, Prog. Mater. Sci. 60, 208 (2014)

H. Deng, H.-r. Li, F. Wang, C.-x. Yuan, S. Liu, P. Wang, L.-z. Xie, Y.-z. Sun, F.-z. Chang, J. Mater. Sci. Mater. Electron 27, 6766 (2016)

K. Han, M. Tao, Sol. Energy Mater. Sol. Cells 93, 153 (2009)

D.P. Dubal, D.S. Dhawale, R.R. Salunkhe, V.S. Jamdade, C.D. Lokhande, J. Alloys Compd. 492, 26 (2010)

A.M. El Sayed, M. Shaban, Spectrochim. Acta A 149, 638 (2015)

M.M. Momeni, M. Mirhosseini, Z. Nazari, A. Kazempour, M. Hakimiyan, J. Mater. Sci. Mater. Electron. 27, 8131 (2016)

R. Zhang, J. Liu, H. Guo, X. Tong, Mater. Lett. 139, 55 (2015)

C.-C. Hsu, C.-H. Wu, S.-Y. Wang, J. Alloys Compd. 663, 262 (2016)

S. Baturay, A. Tombak, D. Kaya, Y.S. Ocak, M. Tokus, M. Aydemir, T. Kilicoglu, J. Sol-Gel Sci. Technol. 78, 422 (2016)

H.Z. Asl, S.M. Rozati, J. Electron. Mater. 46, 5020 (2017)

A.D. Faisal, W.K. Khalef, J. Mater. Sci. Mater. Electron. (2017). https://doi.org/10.1007/s10854-017-7844-z

S. Visalakshi, R. Kannan, S. Valanarasu, H.-S. Kim, A. Kathalingam, R. Chandramohan, Appl. Phys. A 120, 1105 (2015)

A.S.M.S. Rahman, M.A. Islam, K.M. Shorowordi, Procedia Eng. 105, 679 (2015)

F. Zahedi, R.S. Dariani, S.M. Rozati, Mater. Sci. Semicond. Process. 16, 245 (2013)

B. Benhaoua, S. Abbas, A. Rahal, A. Benhaoua, M.S. Aida, Superlattices Microstruct. 83, 78 (2015)

W.-Y. Kim, B.M. Palve, H.M. Pathan, O.-S. Joo, Mater. Chem. Phys. 131, 525 (2011)

C. Bouzidi, H. Bouzouita, A. Timoumi, B. Rezig, Mater. Sci. Eng. B 118, 259 (2005)

K. Khojier, J. Electron. Mater. 46, 5889 (2017)

M. Eslamian, Coatings 4, 60 (2014)

I.S. Yahia, A.A.M. Farag, S. El-Faify, F. Yakuphanoglu, A.A. Al-Ghamdi, Optik 127, 1429 (2016)

F. Gao, X.-J. Liu, J.-S. Zhang, M.-Z. Song, N. Li, J. Appl. Phys. 111, 084507 (2012)

T. Oku, R. Motoyoshi, K. Fujimoto, T. Akiyama, B. Jeyadevan, J. Cuya, J. Phys. Chem. Solids 72, 1206 (2011)

H. Kidowaki, T. Oku, T. Akiyama, J. Phys. Conf. Ser. 352, 012022 (2012)

J. Wang, W.-D. Zhang, W.-X. Ouyang, Y.-X. Yu, Mater. Lett. 154, 44 (2015)

L. Chabane, N. Zebbar, M.L. Zeggar, M.S. Aida, M. Kechouane, M. Trari, Mater. Sci. Semicond. Process. 40, 840 (2015)

C.R. Gobbiner, A.V.M. Ali, D. Kekuda, J. Mater. Sci. Mater. Electron. 26, 9801 (2015)

B.S. Kang, S.-E. Ahn, M.-J. Lee, G. Stefanovich, K.H. Kim, W.X. Xianyu, C.B. Lee, Y. Park, I.G. Baek, B.H. Park, Adv. Mater. 20, 3066 (2008)

K.H. Kim, S.R. Lee, S.E. Ahn, M.J. Lee, B.S. Kang, Thin Solid Films 520, 2272 (2012)

S. Edinger, N. Bansal, M. Bauch, R.A. Wibowo, G. Újvári, R. Hamid, G. Trimmel, T. Dimopoulos, J. Mater. Sci. Mater. Electron. 52, 8591 (2017)

A. Hadri, M. Taibi, M. loghmarti, C. Nassiri, T. Slimani, A. TlemÒ«ani, Mzerd, Thin Solid Films 601, 7 (2016)

H. Behzad, F.E. Ghodsi, J. Mater. Sci. Mater. Electron. 27, 6096 (2016)

B.D. Cullity, Elements of X-Ray Diffraction (Addision-Wesley, Reading, 1956), pp. 96–102

M. Lamri Zeggar, L. Chabane, M.S. Aida, N. Attaf, N. Zebbar, Mater. Sci. Semicond. Process. 30, 645 (2015)

Z. Lin, D. Han, S. Li, J. Therm. Anal. Calorim. 107, 471 (2011)

L. Zhu, J.K. Luo, G. Shao, W.I. Milne, Sol. Energy Mater. Sol. Cells 111, 141 (2013)

A.S. Hassanien, A.A. Akl, Superlattices Microstruct. 89, 153 (2016)

N. Mohamed Basith, J. Judith Vijaya, L. John Kennedy, M. Bououdina, Physica E 53, 193 (2013)

F. Johnson, S.H. Song, J. Abrahamson, R. Liptak, E. Aydil, S.A. Campbell, Sol. Energy Mater. Sol. Cells 132, 515 (2015)

C.-W. Ting, C.P. Thao, D.H. Kuo, Mater. Sci. Semicond. Process. 59, 50 (2017)

I. Rahim, M. Shah, M. Iqbal, F. Wahab, A. Khan, S.H. Khan, Physica B 524, 97 (2017)

M.A. Yeganeh, R. Sh, A. Nozad, R.K. Mamedov, Chin. Phys. B 19, 107207 (2010)

S.K. Cheung, N.W. Cheung, Appl. Phys. Lett. 49, 85 (1986)

G. Turgut, S. Duman, E. Sonmez, F.S. Ozcelik, Mater. Sci. Eng. B 206, 9 (2016)

C.-X. Wang, G.-W. Yang, H.-W. Liu, Y.-H. Han, J.-F. Luo, C.-X. Gao, G.-T. Zou, Appl. Phys. Lett. 84, 2427 (2004)

P. Venkateswari, P. Thirunavukkarasu, M. Ramamurthy, M. Balaji, J. Chandrasekaran, Optik 140, 476 (2017)

F. Yakuphanoglu, M. Kandaz, B.F. Senkal, Thin Solid Films 516, 8793 (2008)

İY. Erdoğan, Ö Güllü, J. Alloys Compd. 492, 378 (2010)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Asl, H.Z., Rozati, S.M. Some physical properties of n-IZO/p-CuO thin film heterojunction diodes completely made by spray pyrolysis. J Mater Sci: Mater Electron 29, 4365–4372 (2018). https://doi.org/10.1007/s10854-017-8385-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8385-1