Abstract

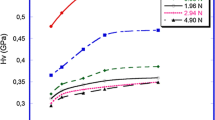

In this study, effect of substitution ratio on the mechanical and structural properties of Bi1−xRuxPb0.2Sr2CaCu2O10+δ system, that is prepared in the ratios of x = 0.0, 0.025, 0.050, 0.075, is investigated. Samples are prepared with glass ceramic method and sintered at 845 °C. XRD and SEM measurements are performed for structural analyses, and Vickers micro-hardness measurements are carried out at different applied load (0.245 ≤ F ≤ 2.940 N) in order to investigate the mechanical performance of the Ru doped Bi1−xRuxPb0.2Sr2CaCu2O10+δ system. Experimental results of Vickers micro-hardness analyses are performed using the Meyer’s law, the proportional samples resistance model, the elastic/plastic deformation model, the Hays–Kendall approach and the indentation induced cracking (IIC) model. All analyses results are exhibited reverse indentation size effect behavior. The measured hardness values increase with increasing the applied load. Finally, IIC model is determined as the most successful model describing the mechanical properties of our samples.

Similar content being viewed by others

References

L. Arda, O. Ozturk, E. Asikuzun, S. Ataoglu, Structural and mechanical properties of transition metals doped ZnMgO nanoparticles. Powder Technol. 235, 479–484 (2013)

O. Sahin, O. Uzun, U. Kolemen, B. Duzgun, N. Ucar, Indentation size effect and microhardness study of β-Sn single crystals. Chin. Phys. Lett. 22, 3137 (2005)

Y. Yoshino, A. Iwabuchi, R. Onodera, A. Chiba, K. Katagiri, T. Shimizu, Vickers hardness properties of structural materials for superconducting magnet at cryogenic temperatures. Cryogenics. 41, 505–511 (2001)

E.M. Onitsch, Mikroskopie. 2, 131–151 (1947)

H. Li, R.C. Bradt, The microhardness indentation load/size effect in rutile and cassiterite single crystals. J. Mater. Sci. 28, 917–926 (1993)

P.P. Maharjan, Q. Chen, L. Zhang, O. Adebanjo, N. Adhikari, S. Venkatesan, P. Adhikary, B. Vaagensmith, Q. Qiao, Photovoltaic devices and characterization of a dodecyloxybenzothiadiazole-based copolymer. Phys. Chem. Chem. Phys. 18, 23628–23637 (2016)

K.R. Reddy, B.C. Sin, C.H. Yoo, W. Park, K.S. Ryu, J.S. Lee, Y. Lee, A new one-step synthesis method for coating multi-walled carbon nanotubes with cuprous oxide nanoparticles. Scripta Mater. 58, 1010–1013 (2008)

Y.P. Zhang, S.H. Lee, K.R. Reddy, A.I. Gopalan, K.P. Lee, Synthesis and characterization of core-shell SiO2nanoparticles/poly(3-aminophenylboronic acid) composites. J. Appl. Polym. Sci. 104, 2743–2750 (2007)

K.R. Reddy, K.P. Lee, A.I. Gopalan, Self-assembly directed synthesis of poly(ortho-toluidine)-metal(gold and palladium) composite nanospheres. J. Nanosci. Nanotechnol. 7, 3117–3125 (2007)

A.M. Showkat, Y.P. Zhang, M.S. Kim, A.I. Gopalan, K.R. Reddy, K. Lee, Analysis of heavy metal toxic ions by adsorption onto amino-functionalized ordered mesoporous silica. Bull. Korean Chem. Soc. 28, 1985–1992 (2007)

K.R. Reddy, K. Nakata, T. Ochiai, T. Murakami, D.A.. Tryk, A. Fujishima, Facile fabrication and photocatalytic application of Ag nanoparticles-TiO2 nanofiber composites. J. Nanosci. Nanotechnol. 11, 3692–3695 (2011)

M. Hassan, E. Haque, K.R. Reddy, A.I. Minett, J. Chen, V.G. Gomes, Edge-enriched graphene quantum dots for enhanced photo-luminescence and supercapacitance. Nanoscale 6, 11988–11994 (2014)

K.R. Reddy, V.G. Gomes, M. Hassan, Carbon functionalized TiO2 nanofibers for high efficiency photocatalysis. Mater. Res. Express 1, 015012 (2014)

M. Cakici, R.R. Kakarla, F. Alonso-Marroquin, Advanced electrochemical energy storage supercapacitors based on the flexible carbon fiber fabric-coated with uniform coral-like MnO2 structured electrodes. Chem. Eng. J. 309, 151–158 (2017)

K.R. Reddy, K.P. Lee, A.I. Gopalan, Self-assembly approach for the synthesis of electro-magnetic functionalized Fe3O4/polyaniline nanocomposites: effect of dopant on the properties. Colloid Surf. A 320, 49–56 (2008)

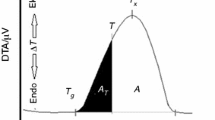

O. Ozturk, T. Gokcen, S. Cavdar, H. Koralay, A. Tasci, A study on nucleation, crystallization kinetics, microstructure and mechanical properties of Ru–Bi partial substituted BSCCO glass ceramics. J. Therm. Anal. Calorim. 123, 1073–1082 (2016)

H. Koralay, O. Hicyilmaz, S. Cavdar, E. Asikuzun, A. Tasci, O. Ozturk, Effect of Zn content on microstructure and mechanical performance in Bi1.8Sr2Ca2Cu3.2–xZnxO10+δ glass ceramic. J. Mater. Sci.: Mater. Electron. 25, 3116–3126 (2014)

O. Ozturk, E. Asikuzun, S. Kaya, G. Yildirim, M. Turkoz, A. Kilic, Improvement of the nature of indentation size effect of Bi-2212 superconducting matrix by doped Nd inclusion and theoretical modeling of new matrix. J. Supercond. Novel Magn. 27, 1403–1412 (2014)

E. Asikuzun, O. Ozturk, H.A. Cetinkara, G. Yildirim, A. Varilci, M. Yilmazlar, C. Terzioglu, Vickers hardness measurements and some physical properties of Pr2O3 doped Bi-2212 superconductors. J. Mater. Sci.: Mater. Electron. 23(5), 1001–1010 (2012)

W.C. Oliver, G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7, 1564–1583 (1992)

D. Tabor, The hardness and strength of metals. J. Inst. Met. 79, 1–18 (1951)

M. Yilmazlar, H.A. Cetinkara, M. Nursoy, O. Ozturk, C. Terzioğlu, Thermal expansion and Vickers hardness of Bi1.6Pb0.4Sr2Ca2–xSmxCu3Oy superconductors. Physica C 442, 101 (2006)

U. Kölemen, O. Uzun, M.A. Aksan, N. Güçlü, E. Yakıncı, An analysis of load depth-sensing microindentation experiments for intermetallic MgB2. J. Alloy. Compd. 415, 294–299 (2006)

H. Aydın, C. Terzioglu, Mechanical and superconducting properties of Bi1.8Pb0.35Sr1.9Ca2.1Cu3 GdxOy. Chin. J. Phys. 47, 192–206 (2009)

X. Chu, S.A. Barnett, Model of superlattice yield stress and hardness enhancements. J. Appl. Phys. 77, 4403 (1995)

O. Ozturk, G. Yildirim, E. Asikuzun, M. Coskunyurek, M. Yilmazlar, A. Kilic, Change of formation velocity of Bi-2212 superconducting phase with annealing ambient. J. Mater. Sci.: Mater. Electron. 24, 4643–4654 (2013)

J. Gong, J. Wu, Z. Guan, Examination of the indentation size effect in low-load Vickers hardness testing of ceramics. J. Eur. Ceram. Soc. 19, 2625–2631 (1999)

A. Elmustafa, D. Stone, Nanoindentation and the indentation size effect: Kinetics of deformation and strain gradient plasticity. J. Mech. Phys. Solids 51, 357–381 (2003)

K. Sangwal, On the reverse indentation size effect and microhardness measurement of solids. Mater. Chem. Phys. 63, 145–152 (2000)

Y. Matsuo, H. Sasaki, Effect of grain size on microcracking in lead titanate ceramics., J. Am. Ceram. Soc. 49, 229–230 (1966)

O. Ozturk, E. Asikuzun, S. Kaya, Significant change in micro mechanical, structural and electrical properties of MgB2 superconducting ceramics depending on argon ambient pressure and annealing duration. J. Mater. Sci.: Mater. Electron. 26, 3840–3852 (2015)

A. Leenders, M. Mich, H. Freyhard, Influence of thermal cycling on the mechanical properties of VGF melt-textured YBCO. Physica C 279, 173–180 (1997)

M. Yilmazlar, O. Ozturk, O. Gorur, I. Belenli, C. Terzioglu, Role of diffusion-annealing time on the mechanical properties of bulk Bi-2223 superconductors diffusion-doped with Au. Supercond. Sci. Technol. 20, 365 (2007)

M. Yilmazlar, H. Cetinkara, M. Nursoy, O. Ozturk, C. Terzioglu, Thermal expansion and Vickers hardness measurements on Bi1.6Pb0.4Sr2Ca2–xSmx Cu3Oy superconductors. Physica C 442, 101–107 (2006)

H. Aydın, A. Babanli, S.P. Altintas, E. Asikuzun, N. Soylu, O. Ozturk, M. Dogruer, C. Terzioglu, G. Yildirim, Breaking point of the harmony between Gd diffused Bi-2223 slabs with diffusion annealing temperature. J. Mater. Sci.: Mater. Electron. 24, 4566–4573 (2013)

S. Celik, O. Ozturk, E. Coşkun, M. Sarıhan, E. Asikuzun, K. Ozturk, C. Terzioglu, Analysis of indentation size effect (ISE) behavior in low-load Vickers microhardness testing of (Sm123)1–x(Nd123)x superconductor system. J. Mater. Sci.: Mater. Electron. 24, 2218–2227 (2013)

G.P. Upit, S.A. Varchenya, Microhardness of alkali halide crystals. Phys. Status Solidi B 17, 831–835 (1966)

S.J. Bull, T.F. Page, E.H. Yoffe, An explanation of the indentation size effect in ceramics. Philos. Mag. Lett. 59, 281–288 (1989)

C. Hays, E. Kendall, An analysis of Knoop microhardness. Metallography 6, 275–282 (1973)

P. Feltham, R. Banerjee, Theory and application of microindentation in studies of glide and cracking in single crystals of elemental and compound semiconductors. J. Mater. Sci. 27, 1626–1632 (1992)

E. Asikuzun, A. Donmez, L. Arda, D. Akcan, O. Ozturk, O. Cakiroglu, M. Tosun, S. Ataoglu, C. Terzioglu, Structural and mechanical properties of (Co/Mg) Co-doped nano ZnO. Ceram. Int. 41, 6326–6334 (2015)

M. Tosun, S. Ataoglu, L. Arda, O. Ozturk, E. Asikuzun, D. Akcan, O. Cakiroglu, Structural and mechanical properties of ZnMgO nanoparticles. Mater. Sci. Eng. A 590, 416–422 (2014)

M.B. Turkoz, S. Nezir, O. Ozturk, E. Asikuzun, G. Yildirim, C. Terzioglu, A. Varilci, Experimental and theoretical approaches on mechanical evaluation of Y123 system by Lu addition. J. Mater. Sci.: Mater. Electron. 24, 2414–2421 (2013)

H. Li, R.C. Bradt, The effect of indentation-induced cracking on the apparent microhardness. J. Mater. Sci. 31, 1065–1070 (1996)

B.R. Lawn, M.V. Swain, Microfracture beneath point indentations in brittle solids. J. Mater. Sci. 10, 113–122 (1975)

B.R. Lawn, E.R. Fuller, Equilibrium penny-like cracks in indentation fracture. J. Mater. Sci. 10, 2016–2024 (1975)

R. Awad, A.A. Aly, M. Kamal, M. Anas, Mechanical properties of (Cu0.5Tl0.5)-1223 substituted by Pr. J. Supercond. Novel Magn. 24, 1947–1956 (2011)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozturk, O., Asikuzun, E., Tasci, A.T. et al. Comparison of Vickers microhardness of undoped and Ru doped BSCCO glass ceramic materials. J Mater Sci: Mater Electron 29, 3957–3966 (2018). https://doi.org/10.1007/s10854-017-8336-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-017-8336-x