Abstract

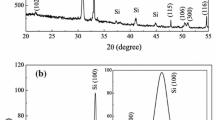

In recent times, due to their highly stable and radiation tolerant nature, interest toward feasibility of developing MAX phase-based applications has suddenly surged. In this context, we for the first time report a comprehensive spin-dependent transport study of Cr2AlC@p–Si-based thin film interfacial structure. Phase purity of the fabricated epitaxial Cr2AlC thin film grown by electron-beam deposition was confirmed from structural, vibrational and elemental analysis. Transport studies showed n-type metallic nature of the deposited Cr2AlC films. Low-temperature transport/magnetic measurements across the interface have shown spin-dependent Schottky behavior. Our results demonstrate the potential of Cr2AlC@p–Si as a novel Schottky interfacial structure for the development of more complex device applications.

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References:

Shah SH, Bristowe PD (2017) Point defect formation in M2AlC (M = Zr, Cr) MAX phases and their tendency to disorder and amorphize. Sci Rep 7:9667. https://doi.org/10.1038/s41598-017-10273-6

Tunes MA, Imtyazuddin M, Kainz C, Pogatscher S, Vishnyakov VM (2021) Deviating from the pure MAX phase concept: radiation-tolerant nanostructured dual-phase Cr2AlC. Sci Adv 7:eabf6771. https://doi.org/10.1126/sciadv.abf6771

Li X, Wang S, Wu G et al (2022) Oxidation and hot corrosion behaviors of MAX-phase Ti3SiC2, Ti2AlC, Cr2AlC. Ceram Int 48:26618–26628. https://doi.org/10.1016/j.ceramint.2022.05.356

Zou X, Zhang Z, Song S, Wang X, Joardar J, Reddy KM (2022) High strength and plasticity in Cr-Al-C composite. Mater Sci Eng A 835:142684. https://doi.org/10.1016/j.msea.2022.142684

Duong TC, Talapatra A, Son W, Radovic M, Arroyave R (2017) On the stochastic phase stability of Ti2AlC-Cr2AlC. Sci Rep 7:5138. https://doi.org/10.1038/s41598-017-05463-1

Shahroudi F, Ghasemi B, Abdolahpour H, Razavi M (2022) Sintering behavior of Cr2AlC MAX phase synthesized by Spark plasma sintering. Int J Appl Ceram Technol 19:1309–1318. https://doi.org/10.1111/ijac.13995

Barsoum MW (2000) The MN+1AXN phases: a new class of solids: thermodynamically stable nanolaminates. Prog Solid State Ch 28:201–281. https://doi.org/10.1016/S0079-6786(00)00006-6

Michel WB, Miladin R (2011) Elastic and mechanical properties of the max phases. Annu Rev Mater Res 41:195–227. https://doi.org/10.1146/annurev-matsci-062910-100448

Radovic M, Barsoum M (2013) MAX phases: bridging the gap between metals and ceramics MAX phases: bridging the gap between metals and ceramics. Am Ceram Soc Bull 92:20–27

Xing G, Wan H, Deng C et al (2022) Thermal stability and selective nitridation of Cr2AlC in nitrogen at elevated temperatures. Ceram Int 48:33151–33159. https://doi.org/10.1016/j.ceramint.2022.07.252

Magnus C, Cooper D, Jantzen C, Lambert H, Abram T, Rainforth M (2021) Synthesis and high temperature corrosion behaviour of nearly monolithic Ti3AlC2 MAX phase in molten chloride salt. Corros Sci 182:109193. https://doi.org/10.1016/j.corsci.2020.109193

Wang Z, Ma G, Liu L et al (2020) High-performance Cr2AlC MAX phase coatings: oxidation mechanisms in the 900–1100 °C temperature range. Corros Sci 167:108492. https://doi.org/10.1016/j.corsci.2020.108492

Tabares E, Kitzmantel M, Neubauer E, Morales AJ, Tsipas SA (2022) Extrusion-based additive manufacturing of Ti3SiC2 and Cr2AlC MAX phases as candidates for high temperature heat exchangers. J Eur Ceram Soc 42:841–849. https://doi.org/10.1016/j.jeurceramsoc.2021.10.042

Wang Z, Wang C, Zhang Y, Wang A, Ke P (2022) M-site solid solution of vanadium enables the promising mechanical and high-temperature tribological properties of Cr2AlC coating. Mater Des 222:111060. https://doi.org/10.1016/j.matdes.2022.111060

Guo Y, Song Y, Wen J et al (2022) Evaluation of microwave absorption performance of annealed Cr2AlC at different temperatures. ECS J Solid State Sci Technol 11:103013. https://doi.org/10.1149/2162-8777/ac95c7

Liu F, Cao H, Li H et al (2022) Effect of annealing on the microstructure, mechanical and electrochemical properties of CrAlC coatings. Surf Coat Technol 447:128800. https://doi.org/10.1016/j.surfcoat.2022.128800

Hajas DE, Baben M, Hallstedt B, Iskandar R, Mayer J, Schneider JM (2011) Oxidation of Cr2AlC coatings in the temperature range of 1230 to 1410 °C. Surf Coat Technol 206:591–598. https://doi.org/10.1016/j.surfcoat.2011.03.086

Ingason AS, Dahlqvist M, Rosen J (2016) Magnetic MAX phases from theory and experiments; a review. J Condens Matter Phys 28:433003. https://doi.org/10.1088/0953-8984/28/43/433003

Schneider JM, Sun Z, Mertens R, Uestel F, Ahuja R (2004) Ab initio calculations and experimental determination of the structure of Cr2AlC. Solid State Commun 130:445–449. https://doi.org/10.1016/j.ssc.2004.02.047

Ramzan M, Lebègue S, Ahuja R (2011) Correlation effects in the electronic and structural properties of Cr2AlC. Phys Status Solidi RRL 5:122–124. https://doi.org/10.1002/pssr.201004508

Jaouen M, Bugnet M, Jaouen N et al (2014) Experimental evidence of Cr magnetic moments at low temperature in Cr2A(A=Al, Ge)C. J Condens Matter Phys 26:176002. https://doi.org/10.1088/0953-8984/26/17/176002

Jaouen M, Chartier P, Cabioc’h T, Mauchamp V, André G, Viret M (2013) Invar like behavior of the Cr2AlC MAX phase at low temperature. J Am Ceram Soc 96:3872–3876. https://doi.org/10.1111/jace.12635

Mockute A, Dahlqvist M, Emmerlich J et al (2013) Synthesis and ab initio calculations of nanolaminated (Cr, Mn)2AlC compounds. Phys Rev B 87:094113. https://doi.org/10.1103/PhysRevB.87.094113

Mockute A, Persson POA, Magnus F et al (2014) Synthesis and characterization of arc deposited magnetic (Cr, Mn)2AlC MAX phase films. Phys Status Solidi RRL 8:420–423. https://doi.org/10.1002/pssr.201409087

Dahlqvist M, Alling B, Abrikosov IA, Rosen J (2011) Magnetic nanoscale laminates with tunable exchange coupling from first principles. Phys Rev B 84:220403. https://doi.org/10.1103/PhysRevB.84.220403

Hettinger JD, Lofland SE, Finkel P et al (2005) Electrical transport, thermal transport, and elastic properties of M2AlC (M=Ti, Cr, Nb, and V). Phys Rev B 72:115120. https://doi.org/10.1103/PhysRevB.72.115120

Stevens M, Pazniak H, Jemiola A, Felek M, Farle M, Wiedwald U (2021) Pulsed laser deposition of epitaxial Cr2lC MAX phase thin films on MgO(111) and Al2O3(0001). Mater Res Lett 9:343–349. https://doi.org/10.1080/21663831.2021.1920510

Lin S, Tong P, Wang BS et al (2013) Magnetic and electrical/thermal transport properties of Mn-doped Mn+1AXn phase compounds Cr2-xMnxGaC (0 <= x <= 1). J Appl Phys 113:053502. https://doi.org/10.1063/1.4789954

Liu Z, Waki T, Tabata Y, Yuge K, Nakamura H, Watanabe I (2013) Magnetic ground state of the Mn+1AX n-phase nitride Cr2GaN. Phys Rev B 88:134401. https://doi.org/10.1007/s11664-013-2882-7

Stelzer B, Chen X, Bliem P et al (2019) Remote tracking of phase changes in Cr2AlC thin films by in-situ resistivity measurements. Sci Rep 9:8266. https://doi.org/10.1038/s41598-019-44692-4

Schuster JC, Nowotny H, Vaccaro C (1980) The ternary systems: CrAlC, VAlC, and TiAlC and the behavior of H-phases (M2AlC). J Solid State Chem 32:213–219. https://doi.org/10.1016/0022-4596(80)90569-1

Kumar A, Srivastava PC (2014) Electronic and magneto-transport across the Heusler alloy (Co2FeAl)/p–Si interfacial structure. J Electron Mater 43:381–388. https://doi.org/10.1007/s11664-013-2882-7

Spanier JE, Gupta S, Amer M, Barsoum MW (2005) Vibrational behavior of the Mn+1AXn phases from first-order Raman scattering (M=Ti, V, Cr, A=Si, X=C, N). Phys Rev B 71:012103. https://doi.org/10.1103/PhysRevB.71.012103

Vishnyakov V, Crisan O, Dobrosz P, Colligon JS (2014) Ion sputter-deposition and in-air crystallisation of Cr2AlC films. Vacuum 100:61–65. https://doi.org/10.1016/j.vacuum.2013.07.045

Davis D, Singh S, Chakradhar RPS, Srivastava M (2020) Tribo-mechanical properties of HVOF-sprayed NiMoAl-Cr2AlC composite coatings. J Therm Spray Technol 29:1763–1783. https://doi.org/10.1007/s11666-020-01069-8

Sharma P, Pandey OP (2019) Non-isothermal oxidation kinetics of nano-laminated Cr2AlC MAX phase. J Alloys Compd 773:872–882. https://doi.org/10.1016/j.jallcom.2018.09.326

Wang SC, Lin HT, Nayak PK, Chang SY, Huang JL (2010) Carbothermal reduction process for synthesis of nanosized chromium carbide via metal-organic vapor deposition. Thin Solid Films 518:7360–7365. https://doi.org/10.1016/j.tsf.2010.05.001

Mullet M, Demoisson F, Humbert B, Michot LJ, Vantelon D (2007) Aqueous Cr (VI) reduction by pyrite: Speciation and characterisation of the solid phases by X-ray photoelectron, Raman and X-ray absorption spectroscopies. Geochim Cosmochim Acta 71:3257–3271. https://doi.org/10.1016/j.gca.2006.09.008

Zamulaeva EI, Levashov EA, Skryleva EA, Sviridova TA, Korneev KPV (2016) Conditions for formation of MAX phase Cr2AlC in electrospark coatings deposited onto titanium alloy. Surf Coat Technol 298:15–23. https://doi.org/10.1016/j.surfcoat.2016.04.058

Agostinelli E, Battistoni C, Fiorani D, Mattogno G, Nogues M (1989) An XPS study of the electronic structure of the ZnxCd1−xCr2(X = S, Se) spinel system. J Phys Chem Solids 50:269–272. https://doi.org/10.1016/0022-3697(89)90487-3

Wagner CD, Passoja DE, Hillery HF et al (1982) Auger and photoelectron line energy relationships in aluminum–oxygen and silicon–oxygen compounds. J Vac Sci Technol A 21:933–944. https://doi.org/10.1116/1.571870

Abdelkader AM (2016) Molten salts electrochemical synthesis of Cr2AlC. J Eur Ceram Soc 36:33–42. https://doi.org/10.1016/j.jeurceramsoc.2015.09.003

Eklund P, Beckers M, Jansson U, Högberg H, Hultman L (2010) The Mn+1AXn phases: materials science and thin-film processing. Thin Solid Films 518:1851–1878. https://doi.org/10.1016/j.tsf.2009.07.184

Rackl T, Johrendt D (2020) The MAX phase borides Zr2SB and Hf2SB. Solid State Sci 106:106316. https://doi.org/10.1016/j.solidstatesciences.2020.106316

Scabarozi TH, Amini S, Finkel P et al (2008) Electrical, thermal, and elastic properties of the MAX-phase Ti2SC. J Appl Phys 104:033502. https://doi.org/10.1063/1.2959738

Tian W, Wang P, Zhang G, Kan Y, Li Y, Yan D (2006) Synthesis and thermal and electrical properties of bulk Cr2AlC. Scr Mater 54:841–846. https://doi.org/10.1016/j.scriptamat.2005.11.009

Ying G, He X, Li M, Du S, Han W, He F (2011) Effect of Cr7C3 on the mechanical, thermal, and electrical properties of Cr2AlC. J Alloys Compd 509:8022–8027. https://doi.org/10.1016/j.jallcom.2011.04.134

Zhou W, Mei B, Zhu J (2009) On the synthesis and properties of bulk ternary Cr2AlC ceramics. Mater Sci Pol 24:973–981

Alialy S, Tecimer H, Uslu H, Altindal S (2017) A comparative study on electrical characteristics of Au/N-Si Schottky diodes, with and without Bi-doped Pva interfacial layer in dark and under illumination at room temperature. J Nanomed Nanotech 4:1000167. https://doi.org/10.4172/2157-7439.1000167

Demirezen S, Altındal S, Uslu I (2013) Two diodes model and illumination effect on the forward and reverse bias I-V and C–V characteristics of Au/PVA (Bi-doped)/n-Si photodiode at room temperature. Curr Appl Phys 13:53–59. https://doi.org/10.1016/j.cap.2012.06.009

Rhoderick EH, Williams RH (1998) Metal-semiconductor contacts. Clarendon, Oxford

Ze SM (1998) Physics of semiconductor devices. John wiley & sons, New York

Hamm CM, Bocarsly JD, Seward G, Kramm UI, Birkel CS (2017) Non-conventional synthesis and magnetic properties of MAX phases (Cr/Mn)2AlC and (Cr/Fe)2AlC. J Mater Chem C 5:5700–5708. https://doi.org/10.1039/C7TC00112F

Siebert JP, Bischoff L, Lepple M et al (2019) Sol-gel based synthesis and enhanced processability of MAX phase Cr2GaC. J Mater Chem C 7:6034–6040. https://doi.org/10.1039/C9TC01416K

Acknowledgements

This work was supported by Indian Institute of Technology Roorkee, India through Post-Doctoral fellowship [Grant No: OH-31-22-609-414]. Authors acknowledge Department of Physics, Banaras Hindu University, India for providing necessary support for sample fabrication and transport measurements and UGC, DAE Consortium, Indore, India for magnetic measurements. The author would also like to thank Prof. Tashi Nautiyal, Department of Physics, IIT Roorkee for her careful reading, suggestions and useful comments on the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding authors state that there is no conflict of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: David Cann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Patel, P.C., Mishra, P.K. & Kandpal, H.C. Study of MAX phase based Schottky interfacial structure: the case of electron-beam deposited epitaxial Cr2AlC film on p–Si (100). J Mater Sci 58, 4041–4053 (2023). https://doi.org/10.1007/s10853-023-08286-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08286-w