Abstract

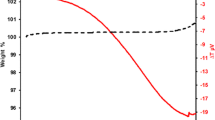

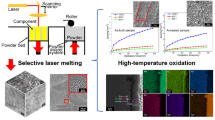

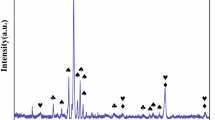

The high temperature oxidation behavior of selective laser melting processed IN738LC alloy at different temperatures was studied using isothermal oxidation testing. The phase composition and oxide layer morphology of the oxidation products under various temperature conditions were characterized by X-ray diffraction (XRD), optical microscopy (OM), and scanning electron microscopy/energy dispersive spectroscopy (SEM/EDS), and the oxidation mechanism was discussed. The results reveal that the oxidation kinetic curves of the deposited samples at 900 and 1000 °C show parabolic law, and the oxidation rate constants kp are 2.54 × 10–4 and 7.68 × 10–4mg2/cm4·h, respectively, where the oxidation products at different temperatures are composed of Al2O3, Cr2O3, and TiO2, which meet the complete oxidation resistance level. Element Cr preferentially oxidizes to produce Cr2O3 during the initial oxidation, Ti atoms at the interface extend the diffusion to the surface of the sample through the Cr2O3 layer to produce TiO2, while the Al atoms rapidly diffuse along the fine columnar grain boundaries toward the oxide–metal interface and finally form a dense Al2O3 layer. The holes formed under the oxide film at 1000 °C will reduce the adhesion between the oxide layer and the substrate, meanwhile adversely affecting the oxidation resistance of the sample.

Similar content being viewed by others

References

Thellaputta GR, Chandra PS, Rao CSP (2017) Machinability of nickel based superalloys: a review. Mater Today: Proc 4:3712–3721. https://doi.org/10.1016/j.matpr.2017.02.266

Perevoshchikova N, Rigaud J, Sha Y et al (2017) Optimisation of selective laser melting parameters for the Ni-based superalloy IN-738LC using Doehlert’s design. Rapid Prototyp J 23:881–892. https://doi.org/10.1108/RPJ-04-2016-0063

Sotov AV, Agapovichev AV, Smelov VG et al (2020) Investigation of the IN-738 superalloy microstructure and mechanical properties for the manufacturing of gas turbine engine nozzle guide vane by selective laser melting. Int J Adv Manuf Technol 107:2525–2535. https://doi.org/10.1007/s00170-020-05197-x

Hays C (2008) Size and shape effects for gamma prime in alloy 738. J Mater Eng Perform 17:254–259. https://doi.org/10.1007/s11665-007-9135-y

Yuan K, Guo W, Li P et al (2018) Influence of process parameters and heat treatments on the microstructures and dynamic mechanical behaviors of Inconel 718 superalloy manufactured by laser metal deposition. Mater Sci Eng A 721:215–225. https://doi.org/10.1016/j.msea.2018.02.014

Pollock TM, Tin S (2006) Nickel-based superalloys for advanced turbine engines: chemistry, microstructure and properties. J Propuls Power 22:361–374. https://doi.org/10.2514/1.18239

Zhang MH, Zhang BC, Wen YJ, Qu XH (2022) Research progress on selective laser melting processing for nickel-based superalloy. Int J Miner Metall Mater 29:1. https://doi.org/10.1007/s12613-021-2331-1

Sing SL, An J, Yeong WY, Wiria FE (2016) Laser and electron-beam powder-bed additive manufacturing of metallic implants: a review on processes, materials and designs. J Orthop Res 34:369–385. https://doi.org/10.1002/jor.23075

Tan XP, Tan YJ, Chow CSL et al (2017) Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: a state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater Sci Eng C 76:1328–1343. https://doi.org/10.1016/j.msec.2017.02.094

Hitzler L, Merkel M, Hall W, Öchsner A (2018) A review of metal fabricated with laser- and powder-bed based additive manufacturing techniques: process, nomenclature, materials, achievable properties, and its utilization in the medical sector. Adv Eng Mater 20:1700658. https://doi.org/10.1002/adem.201700658

Song B, Zhao X, Li S et al (2015) Differences in microstructure and properties between selective laser melting and traditional manufacturing for fabrication of metal parts: a review. Front Mech Eng 10:111–125. https://doi.org/10.1007/s11465-015-0341-2

Geiger F, Kunze K, Etter T (2016) Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specific scanning strategies. Mater Sci Eng A 661:240–246. https://doi.org/10.1016/j.msea.2016.03.036

Rickenbacher L, Etter T, Hövel S, Wegener K (2013) High temperature material properties of IN738LC processed by selective laser melting (SLM) technology. Rapid Prototyp J 19:282–290. https://doi.org/10.1108/13552541311323281

Wang H, Zhang X, Wang GB et al (2019) Selective laser melting of the hard-to-weld IN738LC superalloy: efforts to mitigate defects and the resultant microstructural and mechanical properties. J Alloys Compd 807:151662. https://doi.org/10.1016/j.jallcom.2019.151662

Albert B, Völkl R, Glatzel U (2014) High-temperature oxidation behavior of two nickel-based superalloys produced by metal injection molding for aero engine applications. Metall Mater Trans A 45:4561–4571. https://doi.org/10.1007/s11661-014-2391-1

Yun JY, Park D, Wang JP (2017) A study on the oxidation behavior of nickel alloys at elevated temperatures. IOP Conf Ser Mater Sci Eng 191:012039. https://doi.org/10.1088/1757-899X/191/1/012039

Wangyao P, Polsilapa S, Promboopha A et al (2015) Effect of Al addition in cast nickel base superalloys, inconel-738 on microstructures and oxidation behaviors at 900 °C and 1000 °C. Key Eng Mater 656:39–44. https://doi.org/10.4028/www.scientific.net/KEM.656-657.39

Jia Q, Gu D (2014) Selective laser melting additive manufactured Inconel 718 superalloy parts: high-temperature oxidation property and its mechanisms. Opt Laser Technol 62:161–171. https://doi.org/10.1016/j.optlastec.2014.03.008

Gokcekaya O, Hayashi N, Ishimoto T et al (2020) Crystallographic orientation control of pure chromium via laser powder bed fusion and improved high temperature oxidation resistance. Addit Manuf 36:101624. https://doi.org/10.1016/j.addma.2020.101624

HB 5258–2000. Test method for determination of oxidation resistance of steel and superalloy[S]. Beijing, China Standard Press, 2000: 1–6.

Wang J, Xue H, Wang Y (2021) Oxidation behavior of Ni-based superalloy GH738 in static air between 800 and 1000 °C. Rare Met 40:616–625. https://doi.org/10.1007/s12598-020-01513-2

Kim KS, Yang S, Kim MS, Lee KA (2021) Effect of post heat-treatment on the microstructure and high-temperature oxidation behavior of precipitation hardened IN738LC superalloy fabricated by selective laser melting. J Mater Sci Technol 76:95–103. https://doi.org/10.1016/j.jmst.2020.11.013

Li TF (2003) High-temperature oxidation and thermal corrosion of metals. Chemical Industry Press

Chen JH, Rogers PM, Little JA (1997) Oxidation behavior of several chromia-forming commercial nickel-base superalloys. Oxid Met 47:381–410. https://doi.org/10.1007/BF02134783

Al-hatab KhA, Al-bukhaiti MA, Krupp U, Kantehm M (2011) Cyclic Oxidation behavior of IN 718 superalloy in air at high temperatures. Oxid Met 75:209–228. https://doi.org/10.1007/s11085-010-9230-6

Zhang S, Wang Q, Zhao XS, Zhang CH (2010) High temperature oxidation behavior of cast Ni-based superalloy K444. Shenyang Gongye Daxue XuebaoJournal Shenyang Univ Technol 32:136–140 http://xb.sut.edu.cn/CN/Y2010/V32/I2/136

Lobnig RE, Schmidt HP, Hennesen K, Grabke HJ (1992) Diffusion of cations in chromia layers grown on iron-base alloys. Oxid Met 37:81–93. https://doi.org/10.1007/BF00665632

Loh LE, Chua CK, Yeong WY et al (2015) Numerical investigation and an effective modelling on the Selective Laser Melting (SLM) process with aluminium alloy 6061. Int J Heat Mass Transf 80:288–300. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.014

Zhou X, Li K, Zhang D et al (2015) Textures formed in a CoCrMo alloy by selective laser melting. J Alloys Compd 631:153–164. https://doi.org/10.1016/j.jallcom.2015.01.096

Hu Y, Yang X, Kang W et al (2021) Effect of Zr content on crack formation and mechanical properties of IN738LC processed by selective laser melting. Trans Nonferrous Met Soc China 31:1350–1362. https://doi.org/10.1016/S1003-6326(21)65582-6

Hu Y, Kang W, Zhang H et al (2022) Hot corrosion behavior of IN738LC alloy formed by selective laser melting. Corros Sci 198:110154. https://doi.org/10.1016/j.corsci.2022.110154

Rhines FN, Wolf JS (1970) The role of oxide microstructure and growth stresses in the high-temperature scaling of nickel. Metall Trans 1:1701–1710. https://doi.org/10.1007/BF02642020

Welsch G, Desai PD (1996) Oxidation and Corrosion of Intermetallic Alloys. Metals Information Analysis Center CINDAS. Purdue Univ 148: 154.

Juillet C, Oudriss A, Balmain J et al (2018) Characterization and oxidation resistance of additive manufactured and forged IN718 Ni-based superalloys. Corros Sci 142:266–276. https://doi.org/10.1016/j.corsci.2018.07.032

Doleker KM, Odabas O, Ozgurluk Y et al (2019) Effect of high temperature oxidation on Inconel 718 and Inconel 718/YSZ/Gd2Zr2O7. Mater Res Express 6:086456. https://doi.org/10.1088/2053-1591/ab26d8

Zhao SQ, Xie XS (2006) Hot corrosion behavior of new Ni-Cr-Co based superalloys. Mater Sci Technol 14:506–509. https://doi.org/10.3969/j.issn.1005-0299.2006.05.016

Li TF (2003) High-temperature oxidation and thermal corrosion of metals. Corros Sci Prot Technol 15:94–96

Young DJ (2008) High temperature oxidation and corrosion of metals. Elsevier

Cao JD, Zhang JS, Hua YQ et al (2017) High temperature oxidation behavior of Ni-based superalloy GH586 in air. Rare Met 36:878–885. https://doi.org/10.1007/s12598-016-0823-3

Guo C, Yu Z, Liu C et al (2020) Effects of Y2O3 nanoparticles on the high-temperature oxidation behavior of IN738LC manufactured by laser powder bed fusion. Corros Sci 171:108715. https://doi.org/10.1016/j.corsci.2020.108715

Yu P (2007) The mechanism of the addition of active element Y on the high temperature corrosion behavior of sputtered K38 nanocrystalline coatings. Tianjin University 11–15. https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFD0911&filename=2009071055.nh

Giggins CS, Pettit FS (1971) Oxidation of Ni-Cr-Al alloys between 1000 and 1200 °C. J Electrochem Soc 118:1782–1790. https://doi.org/10.1149/1.2407837

Young DJ (2008) High temperature oxidation and corrosion of metals. Elsevier

Hasegawa M (2014) Ellingham diagramtreatise on process metallurgy. Elsevier

Ndah E, Hierro MP, Borrero K, Pérez FJ (2007) Study of the cyclic oxidation resistance of superalloy IN-625: lifetime predicted by COSP-modelling program. Oxid Met 68:9–21. https://doi.org/10.1007/s11085-006-9048-4

Acknowledgement

This research was supported financially by the Program for Major Projects of Science and Technology in Gansu Province (No. 17ZD2GC011), the Hongliu First-class Discipline Construction Plan of the Lanzhou University of Technology (No. CGZH001), and the Key Research Program of Education Department of Gansu Province (GSSYLXM-03).

Author information

Authors and Affiliations

Contributions

YHwas involved in conceptualization, methodology, supervision, and writing—review. HZ contributed to data curation, and writing—original draft preparation. WK was involved in investigation, validation, and visualization. CC, YH, HZ, DZ contributed to validation and visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Sophie Primig.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, Y., Zhang, HY., Kang, WJ. et al. High temperature oxidation behavior of IN738LC alloy formed by selective laser melting. J Mater Sci 57, 11983–11996 (2022). https://doi.org/10.1007/s10853-022-07345-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07345-y