Abstract

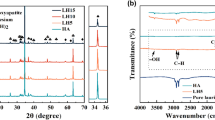

The bacterial infection of bone implants is a vital factor leading to implant failure. Superhydrophobic surface with low adhesion can effectively enhance corrosion resistance and antibacterial adhesion properties of magnesium alloy. Herein, the superhydrophobic composite coating of hydroxyapatite (HA)/stearic acid was successfully prepared on magnesium alloy (AZ31B) using hydrothermal method and followed modification of stearic acid. The wettability, corrosion resistance and antibacterial adhesion capacity of the composite coating were studied. The composite coatings confer excellent superhydrophobicity with a contact angle about 152.52° and a sliding angle about 2°, and showed good long-term superhydrophobic stability in air. Meanwhile, during immersion in simulated body fluid (SBF), the superhydrophobic composite coating was converted to hydrophilicity in a short time and exposed the micro-/nano-scale structure surface of HA, which could induce the fast deposition of the mineralized apatite layer. The characteristics endowed the composite coating with the short-term antibacterial adhesion property and long-term corrosion resistance in SBF, which will afford a surface modification strategy for the application of magnesium alloy implants in orthopedics and dentistry.

Similar content being viewed by others

References

Hu Q, Li B, Wang M, Shen J (2004) Preparation and characterization of biodegradable chitosan/hydroxyapatite nanocomposite rods via in situ hybridization: a potential material as internal fixation of bone fracture. Biomaterials 25:779–785. https://doi.org/10.1016/S0142-9612(03)00582-9

Xu L, Feng P, Yu G, Lei Y, Zhang E, Ke Y (2009) In vitro and in vivo evaluation of the surface bioactivity of a calcium phosphate coated magnesium alloy. Biomaterials 30:1512–1523. https://doi.org/10.1016/j.biomaterials.2008.12.001

Yu H, Dong Q, Doug J, Pan Y, Chen C (2016) Structure and in vitro bioactivity of ceramic coatings on magnesium alloys by microarc oxidation. Appl Surf Sci 388:114–119. https://doi.org/10.1016/j.apsusc.2016.03.028

Zhao D, Witte F, Lu F, Wang J, Qin L (2016) Current status on clinical applications of magnesium-based orthopaedic implants: a review from clinical translational perspective. Biomaterials 112:287–302. https://doi.org/10.1016/j.biomaterials.2016.10.017

Shadanbaz S, Dias GJ (2012) Calcium phosphate coatings on magnesium alloys for biomedical applications: a review. Acta Biomater 8:20–30. https://doi.org/10.1016/j.actbio.2011.10.016

Agarwal S, Curtin J, Duffy B, Jaiswal S (2016) Biodegradable magnesium alloys for orthopaedic applications: a review on corrosion, biocompatibility and surface modifications. Mater Sci Eng C 68:948–963. https://doi.org/10.1016/j.msec.2016.06.020

Dorozhkin SV (2014) Calcium orthophosphate coatings on magnesium and its biodegradable alloys. Acta Biomater 10:2919–2934. https://doi.org/10.1016/j.actbio.2014.02.026

Lin B, Zhong M, Zheng C, Cao L, Wang D, Wang L, Liang J, Cao B (2015) Preparation and characterization of dopamine-induced biomimetic hydroxyapatite coatings on the AZ31 magnesium alloy. Surf Coat Technol 281:82–88. https://doi.org/10.1016/j.surfcoat.2015.09.033

Gu XN, Li N, Zhou WR, Zheng YF, Zhao X, Cai QZ, Ruan L (2011) Corrosion resistance and surface biocompatibility of a microarc oxidation coating on a Mg–Ca alloy. Acta Biomater 7:1880–1889. https://doi.org/10.1016/j.actbio.2010.11.034

Tang H, Han Y, Wu T, Tao W, Jian X, Wu Y, Xu F (2017) Synthesis and properties of hydroxyapatite-containing coating on AZ31 magnesium alloy by micro-arc oxidation. Appl Surf Sci 400:391–404. https://doi.org/10.1016/j.apsusc.2016.12.216

Yu W, Sun R, Guo Z, Wang Z, He Y, Lu G, Chen P, Chen K (2019) Novel fluoridated hydroxyapatite/MAO composite coating on AZ31B magnesium alloy for biomedical application. Appl Surf Sci 464:708–715. https://doi.org/10.1016/j.apsusc.2018.09.148

Li T-T, Ling L, Lin M-C, Jiang Q, Lin Q, Lou C-W, Lin J-H (2019) Effects of ultrasonic treatment and current density on the properties of hydroxyapatite coating via electrodeposition and its in vitro biomineralization behavior. Mater Sci Eng C 105:110062. https://doi.org/10.1016/j.msec.2019.110062

Lian H, Liu X, Meng Z (2019) Enhanced mechanical and osteogenic differentiation performance of hydroxyapatite/zein composite for bone tissue engineering. J Mater Sci 54:719–729. https://doi.org/10.1007/s10853-018-2796-0

Sun J, Cai S, Wei J, Shen Ke XuG (2020) Long-term corrosion resistance and fast mineralization behavior of micro-nano hydroxyapatite coated magnesium alloy in vitro. Ceram Int 46:824–832. https://doi.org/10.1016/j.ceramint.2019.09.038

Shen S, Shu C, Yan L, Rui L, Wang F (2016) Microwave aqueous synthesis of hydroxyapatite bilayer coating on magnesium alloy for orthopedic application. Chem Eng J 309:278–287. https://doi.org/10.1016/j.cej.2016.10.043

Hu H, Zhang W, Qiao Y, Jiang X, Liu X, Ding C (2012) Antibacterial activity and increased bone marrow stem cell functions of Zn-incorporated TiO2 coatings on titanium. Acta Biomater 8:904–915. https://doi.org/10.1016/j.actbio.2011.09.031

Izquierdo-Barba I, García-Martín JM, álvarez R, Palmero A, Esteban J, Pérez-Jorge C, Arcos D, Vallet-Regí M, (2015) Nanocolumnar coatings with selective behavior towards osteoblast and Staphylococcus aureus proliferation. Acta Biomater 15:20–28. https://doi.org/10.1016/j.actbio.2014.12.033

Xu G, Shen X, Dai L, Ran Q, Ma P, Cai K (2017) Reduced bacteria adhesion on octenidine loaded mesoporous silica nanoparticles coating on titanium substrates. Mater Sci Eng C 70:386–395. https://doi.org/10.1016/j.msec.2016.08.050

Hetrick EM, Schoenfisch MH (2006) Reducing implant-related infections: active release strategies. Chem Soc Rev 35:780–789. https://doi.org/10.1039/b515219b

Mokhtari H, Ghasemi Z, Kharaziha M, Karimzadeh F, Alihosseini F (2018) Chitosan-58S bioactive glass nanocomposite coatings on TiO2 nanotube: structural and biological properties. Appl Surf Sci 441:138–149. https://doi.org/10.1016/j.apsusc.2018.01.314

PremKumar KP, Duraipandy N, Kiran MS, Rajendran N (2018) Antibacterial effects, biocompatibility and electrochemical behavior of zinc incorporated niobium oxide coating on 316L SS for biomedical applications. Appl Surf Sci 427:1166–1181. https://doi.org/10.1016/j.apsusc.2017.08.221

Thukkaram M, Cools P, Nikiforov A, Rigole P, Coenye T, Van der Voort P, Du Laing G, Vercruysse C, Declercq H, Morent R, De Wilde L, De Baets P, Verbeken K, De Geyter N (2020) Antibacterial activity of a porous silver doped TiO2 coating on titanium substrates synthesized by plasma electrolytic oxidation. Appl Surf Sci 500:144235. https://doi.org/10.1016/j.apsusc.2019.144235

Sobolev A, Valkov A, Kossenko A, Wolicki I, Zinigrad M, Borodianskiy K (2019) Bioactive coating on Ti alloy with high osseointegration and antibacterial Ag nanoparticles. ACS Appl Mater Interf 11:39534–39544. https://doi.org/10.1021/acsami.9b13849

Campoccia D, Montanaro L, Arciola CR (2013) A review of the biomaterials technologies for infection-resistant surfaces. Biomaterials 34:8533–8554. https://doi.org/10.1016/j.biomaterials.2013.07.089

Wang D, Sun Q, Hokkanen MJ, Zhang C, Lin F-Y, Liu Q, Zhu S-P, Zhou T, Chang Q, He B, Zhou Q, Chen L, Wang Z, Ras RHA, Deng X (2020) Design of robust superhydrophobic surfaces. Nature 582:55–59. https://doi.org/10.1038/s41586-020-2331-8

Li S, Huang J, Zhong C, Chen G, Lai Y (2017) A review on special wettability textiles: theoretical models, fabrication technologies and multifunctional applications. J Mater Chem A 5:31–55. https://doi.org/10.1039/c6ta07984a

Liu Y, Li X, Jin J, Liu J, Yan Y, Han Z, Ren L (2017) Anti-icing property of bio-inspired micro-structure superhydrophobic surfaces and heat transfer model. Appl Surf Sci 400:498–505. https://doi.org/10.1016/j.apsusc.2016.12.219

Falde EJ, Yohe ST, Colson YL, Grinstaff MW (2016) Superhydrophobic materials for biomedical applications. Biomaterials 104:87–103. https://doi.org/10.1016/j.biomaterials.2016.06.050

Xu S, Wang Q, Wang N, Zheng X (2019) Fabrication of superhydrophobic green surfaces with good self-cleaning, chemical stability and anti-corrosion properties. J Mater Sci 54:13006–13016. https://doi.org/10.1007/s10853-019-03789-x

Zhang X, Wang L, LevaNen E (2013) Superhydrophobic surfaces for the reduction of bacterial adhesion. RSC Adv 3:12003–12020. https://doi.org/10.1039/c3ra40497h

Liu Y, Yin X, Zhang J, Yu S, Han Z, Ren L (2014) A electro-deposition process for fabrication of biomimetic super-hydrophobic surface and its corrosion resistance on magnesium alloy. Electrochim Acta 125:395–403. https://doi.org/10.1016/j.electacta.2014.01.135

Zhang Y, Feyerabend F, Tang S, Hu J, Lu X, Blawert C, Lin T (2017) A study of degradation resistance and cytocompatibility of super-hydrophobic coating on magnesium. Mater Sci Eng, C 78:405–412

Lei L, Wang Q, Xu S, Wang N, Zheng X (2020) Fabrication of superhydrophobic concrete used in marine environment with anti-corrosion and stable mechanical properties. Constr Build Mater 251:118946. https://doi.org/10.1016/j.conbuildmat.2020.118946

Li Y, Weng W (2008) Surface modification of hydroxyapatite by stearic acid: characterization and in vitro behaviors. J Mater Sci-Mater M 19:19–25. https://doi.org/10.1007/s10856-007-3123-5

Je S, Cai S, Sun J, Ke S, Liu J, Xu G (2019) Ultrasonic aqueous synthesis of corrosion resistant hydroxyapatite coating on magnesium alloys for the application of long-term implant. Ultrason Sonochem 58:104677. https://doi.org/10.1016/j.ultsonch.2019.104677

ASTM G31–72 (2004) Standard practice for laboratory immersion corrosion testing of metals, Philadelphia, PA, USA

Zang D, Zhu R, Zhang W, Yu X, Lin L, Guo X, Liu M, Jiang L (2017) Corrosion-resistant superhydrophobic coatings on mg alloy surfaces inspired by lotus seedpod. Adv Funct Mater 27:1605446. https://doi.org/10.1002/adfm.201605446

Zhang X, Si Y, Mo J, Guo Z (2017) Robust micro-nanoscale flowerlike ZnO/epoxy resin superhydrophobic coating with rapid healing ability. Chem Eng J 313:1152–1159. https://doi.org/10.1016/j.cej.2016.11.014

Lin K, Chang J, Zhu Y, Wu W, Cheng G, Zeng Y, Ruan M (2009) A facile one-step surfactant-free and low-temperature hydrothermal method to prepare uniform 3d structured carbonated apatite flowers. Cryst Growth Des 9:177–181. https://doi.org/10.1021/cg800129u

Iyyappan E, Wilson P, Sheela K, Ramya R (2016) Role of triton X-100 and hydrothermal treatment on the morphological features of nanoporous hydroxyapatite nanorods. Mater Sci Eng C 63:554–562. https://doi.org/10.1016/j.msec.2016.02.076

Ren Y, Zhou H, Nabiyouni M, Bhaduri SB (2015) Rapid coating of AZ31 magnesium alloy with calcium deficient hydroxyapatite using microwave energy. Mater Sci Eng C 49:364–372. https://doi.org/10.1016/j.msec.2015.01.046

Liu Q, Chen D, Kang Z (2015) One-step electrodeposition process to fabricate corrosion-resistant superhydrophobic surface on magnesium alloy. ACS Appl Mater Interf 7:1859–1867. https://doi.org/10.1021/am507586u

Jie H, Xu Q, Wei L, Min Y (2016) Etching and heating treatment combined approach for superhydrophobic surface on brass substrates and the consequent corrosion resistance. Corros Sci 102:251–258. https://doi.org/10.1016/j.corsci.2015.10.013

Lv Z, Yu S, Song K, Zhou X, Yin X (2020) Fabrication of a leaf-like superhydrophobic CuO coating on 6061Al with good self-cleaning, mechanical and chemical stability. Ceram Int 46:14872–14883. https://doi.org/10.1016/j.ceramint.2020.03.013

Zhang X, Li Q, Li L, Zhang P, Wang Z, Chen F (2012) Fabrication of hydroxyapatite/stearic acid composite coating and corrosion behavior of coated magnesium alloy. Mater Lett 88:76–78. https://doi.org/10.1016/j.matlet.2012.08.011

Brady RF (1994) Coming to an unsticky end. Nature 368:16–17

Li H, Yu S, Han X (2016) Fabrication of CuO hierarchical flower-like structures with biomimetic superamphiphobic, self-cleaning and corrosion resistance properties. Chem Eng J 283:1443–1454. https://doi.org/10.1016/j.cej.2015.08.112

Chen Z, Mao X, Tan L, Friis T, Wu C, Crawford R, Xiao Y (2014) Osteoimmunomodulatory properties of magnesium scaffolds coated with beta-tricalcium phosphate. Biomaterials 35:8553–8565. https://doi.org/10.1016/j.biomaterials.2014.06.038

Cui LY, Gao SD, Li PP, Zeng RC, Zhang F, Li SQ, Han EH (2017) Corrosion resistance of a self-healing micro-arc oxidation/polymethyltrimethoxysilane composite coating on magnesium alloy AZ31. Corros Sci 118:84–95. https://doi.org/10.1016/j.corsci.2017.01.025

Eriksson C, Nygren H, Ohlson K (2004) Implantation of hydrophilic and hydrophobic titanium discs in rat tibia: cellular reactions on the surfaces during the first 3 weeks in bone. Biomaterials 25:4759–4766. https://doi.org/10.1016/j.biomaterials.2003.12.006

Lin Y, Cai S, Jiang S, Xie D, Ling R, Sun J, Wei J, Shen K, Xu G (2019) Enhanced corrosion resistance and bonding strength of Mg substituted beta-tricalcium phosphate/Mg(OH)2 composite coating on magnesium alloys via one-step hydrothermal method. J Mech Behav Biomed 90:547–555. https://doi.org/10.1016/j.jmbbm.2018.11.007

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27:2907–2915. https://doi.org/10.1016/j.biomaterials.2006.01.017

Shen S, Cai S, Li Y, Ling R, Zhang F, Xu G, Wang F (2017) Microwave aqueous synthesis of hydroxyapatite bilayer coating on magnesium alloy for orthopedic application. Chem Eng J 309:278–287. https://doi.org/10.1016/j.cej.2016.10.043

Kokubo T, Matsushita T, Takadama H (2007) Titania-based bioactive materials. J Eur Ceram Soc 27:1553–1553. https://doi.org/10.1016/j.jeurceramsoc.2006.04.015

Bos R, van der Mei HC, Busscher HJ (1999) Physico-chemistry of initial microbial adhesive interactions-its mechanisms and methods for study. FEMS Microbiol Rev 23:179–230. https://doi.org/10.1016/s0168-6445(99)00004-2

Ren T, Yang M, Wang K, Zhang Y, He J (2018) CuO nanoparticles-containing highly transparent and superhydrophobic coatings with extremely low bacterial adhesion and excellent bactericidal property. ACS Appl Mater Interf 10:25717–25725. https://doi.org/10.1021/acsami.8b09945

Leung YH, Ng AMC, Xu X, Shen Z, Gethings LA, Wong MT, Chan CMN, Guo MY, Ng YH (2014) Mechanisms of antibacterial activity of MgO: non-ROS mediated toxicity of MgO nanoparticles towards escherichia coli. Small 10:1171–1183. https://doi.org/10.1002/smll.201302434

Reddy KM, Feris K, Bell J, Wingett DG, Hanley C, Punnoose A (2007) Selective toxicity of zinc oxide nanoparticles to prokaryotic and eukaryotic systems. Appl Phys Lett 90:2139021–2139023. https://doi.org/10.1063/1.2742324

Acknowledgements

This study was funded by the National Natural Science Foundation of China [grant numbers. 51872197, 51572186, 51802221].

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Q., Bao, X., Sun, J. et al. Fabrication of superhydrophobic composite coating of hydroxyapatite/stearic acid on magnesium alloy and its corrosion resistance, antibacterial adhesion. J Mater Sci 56, 5233–5249 (2021). https://doi.org/10.1007/s10853-020-05592-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05592-5