Abstract

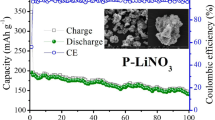

An oxalate-based hydrothermal approach has been applied to synthesize Ni0.8Mn0.1Co0.1·C2O4·2H2O “mixed oxalate,” and “mixed oxalate” has been lithiated to LiNi0.8Mn0.1Co0.1O2 for Li-ion batteries cathode. Ni2+, Mn2+ and Co2+ can be precipitated quickly and effectively at 100 °C within 20 min without inert gas protection, and it was not needed to control the pH of the solution deliberately. After the “mixed oxalate” was lithiated to LiNi0.8Mn0.1Co0.1O2, as-synthesized LiNi0.8Mn0.1Co0.1O2 can deliver 160–180 mAh g−1 at 1C during long-term cycling and showed one of the best electrochemical performances compared to some Ni-rich or Ni/Mn/Co-contained cathodes synthesized by similar procedures, i.e., higher reversible capacity in rate charge/discharge cycles. Considering the facile synthesis of “mixed oxalate,” this work may give rise to an inspiration for LiNixMnyCo1−x−yO2 cathodes research.

Similar content being viewed by others

References

Ghassan Z, Rodolfo DL, Monica C et al (2018) The lithium-ion battery: state of the art and future perspectives. Renew Sustain Energy Rev 89:292–308

Richard S, Ralf W, Gerhard H et al (2018) Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat Energy 3:267–278

Li M, Lu J, Chen Z et al (2018) 30 years of lithium-ion batteries. Adv Mater 30(33):1800561

Tomohiro Y, Kenta H, Ryo M (2019) First-principles study of structural transitions in LiNiO2 and high throughput screening for long life battery. J Phys Chem C 123:14126–14131

Matteo B, Maria RA, Pascal H et al (2019) There and back again-the journey of LiNiO2 as a cathode active material. Angew Chem Int Ed 58:10434–10458

Xin FX, Zhou H, Chen XB et al (2019) Li–Nb–O coating/substitution enhances the electrochemical performance of the LiNi0.8Mn0.1Co0.1O2 (NMC 811) cathode. ACS Appl Mater Interfaces 11:34889–34894

Wu JX, Tan XH, Zhang JT et al (2019) Improvement of electrochemical performance of nickel rich LiNi0.8Co0.1Mn0.1O2 cathode by lithium aluminates surface modifications. Energy Technol 7:209–215

Huang B, Wang M, Zhao ZY et al (2019) Effects of the strong oxidant treatment of precursor on the electrochemical properties of LiNi0.8Mn0.1Co0.1O2 for lithium-ion batteries. J Alloys Compd 810:151800

Li Y, Lai FY, Zhang XH et al (2019) Surface modification of Sr-doped LaMnO3 coating by spray drying on Ni-rich LiNi0.8Mn0.1Co0.1O2 cathode material for lithium-ion batteries. J Taiwan Inst Chem E 102:225–232

Wu K, Li Q, Dang RB, Deng X et al (2019) A novel synthesis strategy to improve cycle stability of LiNi0.8Mn0.1Co0.1O2 at high cut-off voltages through core-shell structuring. Nano Res 12:2460–2467

Lu HQ, Zhou HT, Ann MS et al (2013) High capacity Li[Ni0.8Co0.1Mn0.1]O2 synthesized by sol-gel and co-precipitation methods as cathode materials for lithium-ion batteries. Solid State Ion 249–250:105–111

Ma F, Wu YH, Wei GY et al (2019) Comparative study of simple and concentration gradient shell coatings with Li1.2Ni0.13Mn0.54Co0.13O2 on LiNi0.8Mn0.1Co0.1O2 cathodes for lithium-ion batteries. Solid State Ion 341:115034

Fan JM, Li GS, Luo D et al (2015) Hydrothermal-assisted synthesis of Li-rich layered oxide microspheres with high capacity and superior rate-capability as a cathode for lithium-ion batteries. Electrochim Acta 173:7–16

Zhang JW, Guo X, Yao SM et al (2013) Tailored synthesis of Ni0.25Mn0.75CO3 spherical precursor for high capacity Li-rich cathode materials via a urea-based precipitation method. J Power Sources 238:245–250

Nan Liu, Chen XY, Zhang JL et al (2014) A review on TiO2-based nanotubes synthesized via hydrothermal method: formation mechanism, structure modification, and photocatalytic applications. Catal Today 225:34–51

Shi Y, Zhang MH, Fang CC et al (2018) Urea-based hydrothermal synthesis of LiNi0.5Co0.2Mn0.3O2 cathode material for Li-ion battery. J Power Sources 394:114–121

Li Q, Fung KY, Ng KM (2019) Separation of Ni Co, and Mn from spent LiNi0.5Mn0.3Co0.2O2 cathode materials by ammonia dissolution. ACS Sustain Chem Eng 7(15):12718–12725

Teng HN, Wang XY, Hou YX et al (2016) Properties and extraction for [Ni(NH3)6]2+ of ATPS-a formed by aqueous cationic-anionic surfactant mixtures. Sci Technol 37:830–835

Feng W, Lu HQ, Su YF et al (2010) Preparation and electrochemical performance of Li-rich layered cathode material, Li[Ni0.2Li0.2Mn0.6]O2, for lithium-ion batteries. J Appl Electrochem 40:783–789

Huang B, Zhao ZY, Sun YZ et al (2019) Lithium-ion conductor LiAlO2 coated LiNi0.8Mn0.1Co0.1O2 as cathode material for lithium-ion batteries. Solid State Ion 338:31–38

Arof AK (2008) Characteristics of LiMO2 (M = Co, Ni, Ni0.2Co0.8, Ni0.8Co0.2) powders prepared from solution of their acetates. J Alloys Compd 449:288–291

Ahn J, Susanto D, Noh JK et al (2017) Achieving high capacity and rate capability in layered lithium transition metal oxide cathodes for lithium-ion batteries. J Power Sources 360:575–584

Gao SL, Yang TH, Zhang HZ et al (2017) Improved electrochemical performance and thermal stability of Li-rich material Li1.2(Ni0.25Co0.25Mn0.5)0.8O2 through a novel core-shelled structure design. J Alloys Compd 729:695–702

He DZ, Guo QX, Yin H et al (2017) Sol–gel combustion synthesis of Li1.2Mn0.54Ni0.13Co0.13O2 as cathode materials for lithium ion batteries. Int J Electrochem Sci 12:455–465

Yang ZH, Lu JB, Bian DH et al (2014) Stepwise co-precipitation to synthesize LiNi1/3Co1/3Mn1/3O2 one-dimensional hierarchical structure for lithium ion batteries. J Power Sources 272(2014):144–151

Chen Z, Chao DL, Liu JL et al (2017) 1D nanobar-like LiNi0.4Co0.2Mn0.4O2 as a stable cathode material for lithium-ion batteries with superior long-term capacity retention and high rate capability. J Mater Chem A 5:15669–15675

Li Y, Li XH, Wang ZL et al (2018) An ostwald ripening route towards Ni-rich layered cathode material with cobalt-rich surface for lithium ion battery. Sci China Mater 61:719–727

Hendri W, Atika NS, Heri S et al (2019) Synthesis of LiNi0.8Mn0.1Co0.1O2 cathode material by hydrothermal method for high energy density lithium ion battery. J Phys: Conf Ser 1153:012074

Mintarsih R, Agus P, Hendri W et al (2020) Synthesis of NMC 111 via urea assisted solid state method. AIP Conf Proc 2197:050007

Ryo A, Petr N, Rosa R (2017) Colloidal synthesis and electrochemistry of surface coated nano-LiNi0.80Co0.15Al0.05O2. J Electrochem Soc 164(12):A2617–A2624

Wu NT, Wu H, Yuan W et al (2015) Facile synthesis of one-dimensional LiNi0.8Co0.15Al0.05O2 microrods as advanced cathode materials for lithium ion batteries. J Mater Chem A 3(26):13648–13652

Lele P, Yue Z, Umair K et al (2015) Self-assembled LiNi1/3Co1/3Mn1/3O2 nanosheet cathodes with tunable rate capability. Nano Energy 17:36–42

Seo JS, Lee JW (2017) Fast growth of the precursor particles of Li(Ni0.8Co0.16Al0.04)O2 via a carbonate co-precipitation route and its electrochemical performance. J Alloys Compd 694:703–709

Peng D, Xia SB, Zhang YJ et al (2017) Influence of complexing agents on the structure and electrochemical properties of LiNi0.80Co0.15Al0.05O2 cathode synthesized by sol–gel method: a comparative study. Int J Electrochem Sci 12:561–575

Acknowledgements

This work was financially supported by the 973 program of Ministry of Science and Technology of the People’s Republic of China (No. 2013CB934700), the National Natural Science Foundation of China (Nos. 51222305 and 51673123) and the Program for New Century Excellent Talents in University (No. NCET-12-0386).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, T., Zhang, C. An effective way of co-precipitating Ni2+, Mn2+ and Co2+ by using ammonium oxalate as precipitant for Ni-rich Li-ion batteries cathode. J Mater Sci 55, 11535–11544 (2020). https://doi.org/10.1007/s10853-020-04753-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04753-w