Abstract

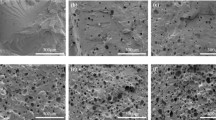

Novatein® is a patented thermoplastic biopolymer produced from denatured haemoglobin and serum albumin proteins, in blood meal. This material is biodegradable after processing, and when foamed could provide an alternative to expanded polystyrene and polyurethane for short-term applications such as packaging. This study aims to investigate the effect of processing temperature on foam density and morphology and how these properties effect compression behaviour. Unconstrained rapid expansion produced a range of foam densities, 0.28–0.45 g/cm3, which were strongly dependant on temperature. The foams had compressive strengths between 200 and 600 kPa and an elastic moduli between 2.2 and 8 MPa. Under compression, high-density foams behaved like traditional plastic foams, while at low density they behaved more elastomeric. Models for open and closed cells successfully predicted the compression modulus and strength in the linear elastic region. The foams demonstrated a mixed mode morphology (open and closed cells) and an irregular distribution of cells, which explained the deviation from the models.

Similar content being viewed by others

References

Pickering KL, Verbeek CJR, Viljoen C, Van Den Berg LE (2012) Plastics material. USA Patent US 20100234515 A1

Verbeek CJR, van den Berg LE (2010) Extrusion processing and properties of protein-based thermoplastics. Macromol Mater Eng 295(1):10–21

Parker K, Garancher J-P, Shah S, Fernyhough A (2011) Expanded polylactic acid-an eco-friendly alternative to polystyrene foam. J Cell Plast 47(3):233–243

Nofar M, Park CB (2014) Poly (lactic acid) foaming. Prog Polym Sci 39(10):1721–1741

Garancher J-P, Fernyhough A (2012) Crystallinity effects in polylactic acid-based foams. J Cell Plast 48(5):387–397

Kaisangsri N, Kerdchoechuen O, Laohakunjit N (2014) Characterization of cassava starch based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydr Polym 110(1):70–77

Mariam I, Cho KY, Rizvi SSH (2008) Thermal properties of starch-based biodegradable foams produced using supercritical fluid extrusion (SCFX). Int J Food Prop 11(2):415–426

Pushpadass HA, Babu GS, Weber RW, Hanna MA (2008) Extrusion of starch-based loose-fill packaging foams: effects of temperature, moisture and talc on physical properties. Packag Technol Sci 21(3):171–183

Salgado PR, Schmidt VC, Ortiz SEM, Mauri AN, Laurindo JB (2008) Biodegradable foams based on cassava starch, sunflower proteins and cellulose fibers obtained by a baking process. J Food Eng 85(3):435–443

Tatarka PD, Cunningham RL (1998) Properties of protective loose-fill foams. J Appl Polym Sci 67(7):1157–1176

Schwier C, Krishnaswamy R (2010) Polyhydroxyalkanoates (PHA) bioplastic packaging materials. Report, Metabolix Inc, Cambridge

Dix SE, Anderson JR, Lindenfelzer ME (2013) Method of forming polymeric foam and related foam articles. USA Patent 20130303645

Szegda D, Tarverdi K, Duangphet S, Song J (2014) Extrusion foaming of PHBV. J Cell Plast 50(2):145–162

Richards E, Rizvi R, Chow A, Naguib H (2008) Biodegradable composite foams of PLA and PHBV using subcritical CO2. J Polym Environ 16(4):258–266

Di Maio E, Mensitieri G, Iannace S, Nicolais L, Li W, Flumerfelt R (2005) Structure optimization of polycaprolactone foams by using mixtures of CO2 and N2 as blowing agents. Polym Eng Sci 45(3):432–441

Salerno A, Di Maio E, Iannace S, Netti P (2011) Solid-state supercritical CO2 foaming of PCL and PCL-HA nano-composite: effect of composition, thermal history and foaming process on foam pore structure. J Supercrit Fluids 58(1):158–167

Mungara P, Zhang JW, Jane J (1998) Extrusion processing of soy protein-based foam. Polym Prepr 39(2):148–149

Walallavita A, Verbeek CJR, Lay MC (2015) Blending Novatein thermoplastic protein with pla for carbon dioxide assisted batch foaming. Paper presented at the 31st international conference of the polymer processing society, Jeju Island, South Korea

Gavin C, Lay MC, Verbeek CJR (2015) Extrusion foaming of protein-based thermoplastic and polyethylene blends. Paper presented at the 31st international conference of the polymer processing society–conference papers, Jeju Island, South Korea

Jane J-L, Zhang SS (1998) Soy protein-based thermoplastic composition for foamed articles. USA Patent 5710190A

Gendron R (ed) (2005) Rheological behavior relevant to extrusion foaming. In: Thermoplastic foam processing: principles and development. Polymeric foams, 1st edn. CRC Press, Boca Raton

Ramesh NS (2004) Fundamentals of bubble nucleation and growth in polymers. In: Lee ST, Ramesh NS (eds) Polymeric materials: mechanisms and materials, 1st edn. CRC Press, Boca Raton, pp 81–119

Saengow C, Giacomin AJ, Wú X, Kolitawong C, Aumnate C, Mix AW (2016) Bubble growth from first principles. Can J Chem Eng 94(8):1560–1575

Nawaby AV, Zhang Z (2004) Solubility and diffusivity. In: Gendron R (ed) Thermoplastic foam processing: principles and development. Polymeric foams, 1st edn. CRC Press, Boca Raton, pp 81–119

Lee ST, Park CB (2014) Foam extrusion: principles and practice, 2nd edn. Taylor & Francis, Boca Raton

Michaeli W, Cramer A, Florez L (2009) Process and process analysis of foam injection molding with physical blowing agents. In: Lee ST, Scholz D (eds) Polymeric foams: technology and developments in regulation, process and products. Polymeric foams series. CRC Press, Boca Raton, pp 102–120

Lee S, Kareko L, Jun J (2008) Study of thermoplastic PLA foam extrusion. J Cell Plast 44(4):293–305

Gibson LJ, Ashby MF (1997) Cellular solids: structure and properties. Cambridge University Press, Cambridge

Mills NJ, Zhu HX (1999) The high strain compression of closed-cell polymer foams. J Mech Phys Solids 47(3):669–695

Chen L, Rende D, Schadler LS, Ozisik R (2013) Polymer nanocomposite foams. J Mater Chem A 1(12):3837–3850

Christensen R (1986) Mechanics of low density materials. J Mech Phys Solids 34(6):563–578

Saint-Michel F, Chazeau L, Cavaillé J-Y, Chabert E (2006) Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos Sci Technol 66(15):2700–2708

Zhu HX, Hobdell JR, Windle AH (2000) Effects of cell irregularity on the elastic properties of open-cell foams. Acta Mater 48(20):4893–4900

Mohan VB (2010) Rheology and processing of novatein thermoplastic protein. University of Waikato, Hamilton

Bier JM, Verbeek CJ, Lay MC (2014) Thermal transitions and structural relaxations in protein-based thermoplastics. Macromol Mater Eng 299(5):524–539

Park CB, Baldwin DF, Suh NP (1995) Effect of the pressure drop rate on cell nucleation in continuous processing of microcellular polymers. Polym Eng Sci 35(5):432–440

Filli M, Sjoqvist M, Ohgren C, Stading M, Rigdahl M (2011) Development and characterization of extruded biodegradable foams based on zein and pearl millet flour. Annu Trans NRS 19:1–7

Liu B, Jiang L, Zhang J (2011) Extrusion foaming of poly (lactic acid)/soy protein concentrate blends. Macromol Mater Eng 296(9):835–842

Kuncir EJ, Wirta RW, Golbranson FL (1990) Load-bearing characteristics of polyethylene foam: an examination of structural and compression properties. J Rehabil Res Dev 27(3):229

Bier JM, Verbeek CJR, Lay MC (2013) Thermal and mechanical properties of bloodmeal-based thermoplastics plasticized with tri(ethylene glycol). Macromol Mater Eng 299(1):85–95

Wu Q, Sundborg H, Andersson RL, Peuvot K, Guex L, Nilsson F, Hedenqvist MS, Olsson RT (2017) Conductive biofoams of wheat gluten containing carbon nanotubes, carbon black or reduced graphene oxide. RSC Adv 7(30):18260–18269

Rodríguez-Pérez M, Rodríguez-Llorente S, De Saja J (1997) Dynamic mechanical properties of polyolefin foams studied by DMA techniques. Polym Eng Sci 37(6):959–965

Bier JM, Verbeek CJR, Lay MC (2013) Identifying transition temperatures in bloodmeal-based thermoplastics using material pocket DMTA. J Therm Anal Calorim 112(3):1303–1315

Acknowledgements

The authors would like to acknowledge the contributions of the Biopolymer Network Ltd (BPN), Aduro Biopolymers (Novatein® commercialisation), and the funding received from the New Zealand Ministry of Business, Innovation and Employment (BPLY1302 contract).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gavin, C., Verbeek, C.J.R. & Lay, M.C. Morphology and compressive behaviour of foams produced from thermoplastic protein. J Mater Sci 53, 15703–15716 (2018). https://doi.org/10.1007/s10853-018-2714-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2714-5