Abstract

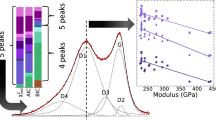

Real-space methods of characterizing high-performance fibers’ inherent morphologies will greatly enhance our understanding of the key structural features within fibers and their impacts on mechanical performance. Here, we report on structure–property correlations of two new classes of commercial DuPont Kevlar fibers, termed “K29 sample test” and “K49 sample test,” as well as conventional K29 and K49 fibers.* Through multifrequency atomic force microscope scans of internal fiber surfaces prepared by a focused ion beam notch technique, we directly capture nano- and microstructural features that define the inherent structures of these fibers. Integrating these findings with X-ray scattering experiments, we relate crystallographic and real-space measurements to each other, highlighting how multiscale structural motifs manifest within fibers. By carrying out tensile tests on single fibers drawn from the same tows, we also glean new insights into the structure–property relationships that dictate the mechanical behavior of these fibers.

Similar content being viewed by others

References

Blades H (1975) High modulus, high tenacity poly (p-phenylene terephthalamide) fiber. US Patent 3869430

Dobb MG, Johnson DJ, Saville BP (1977) Supramolecular structure of a high-modulus polyaromatic fiber (Kevlar 49). J Polym Sci: Polym Phys Edn 15(12):2201–2211

Northolt M (1980) Tensile deformation of poly (p-phenylene terephthalamide) fibres, an experimental and theoretical analysis. Polymer 21(10):1199–1204

Rao Y, Waddon AJ, Farris RJ (2001) Structure–property relation in poly (p-phenylene terephthalamide)(PPTA) fibers. Polymer 42(13):5937–5946

Morgan RJ, Pruneda CO, Steele WJ (1983) The relationship between the physical structure and the microscopic deformation and failure processes of poly (p-phenylene terephthalamide) fibers. J Polym Sci, Part B: Polym Phys 21(9):1757–1783

Panar M et al (1983) Morphology of poly (p-phenylene terephthalamide) fibers. J Polym Sci: Polym Phys Edn 21(10):1955–1969

Chatzi E, Urban M, Koenig J (1986) Characterization of Kevlar fiber surfaces using a newly developed infrared photoacoustic technique. In: Macromolecular symposia. Wiley Online Library

Allen S, Roche E (1989) Deformation behaviour of Kevlar aramid fibres. Polymer 30(6):996–1003

Dobb MG, Robson RM (1990) Structural characteristics of aramid fibre variants. J Mater Sci 25(1):459–464. https://doi.org/10.1007/BF00714056

Northolt M, Van Aartsen J (1977) Chain orientation distribution and elastic properties of poly (p‐phenylene terephthalamide), a “rigid rod” polymer. In: Journal of Polymer Science: Polymer Symposia, Wiley Online Library

Krause S, Vezie D, Adams W (1989) Straightening of pleated sheet structure in fibres of poly (p-phenyleneterephthalamide)-Kevlar 149. Polym Commun 30(1):10–13

Stockdale TA et al (2016) A rapid FIB-notch technique for characterizing the internal morphology of high-performance fibers. Mater Lett 176:173–176

Strawhecker KE et al (2016) Interior morphology of high-performance polyethylene fibers revealed by modulus mapping. Polymer 103:224–232

Roenbeck MR et al (2017) Probing the internal structures of Kevlar fibers and their impacts on mechanical performance. Polymer 128(5):200–210

Cline J, Wu V, Moy P (2018) Assessment of the Tensile properties for single fibers. US Army Research Laboratory, p 1–40

Wagner HD, Phoenix SL, Schwartz P (1984) A study of statistical variability in the strength of single aramid filaments. J Compos Mater 18(4):312–338

Garcia R, Herruzo ET (2012) The emergence of multifrequency force microscopy. Nat Nanotechnol 7(4):217

Garcia R, Proksch R (2013) Nanomechanical mapping of soft matter by bimodal force microscopy. Eur Polymer J 49(8):1897–1906

Herruzo ET, Perrino AP, Garcia R (2014) Fast nanomechanical spectroscopy of soft matter. Nat Commun 5:3126

Labuda A et al (2016) Generalized Hertz model for bimodal nanomechanical mapping. Beilstein J Nanotechnol 7(1):970–982

Kocun M et al (2017) Fast, high resolution, and wide modulus range nanomechanical mapping with bimodal tapping mode. ACS Nano 11(10):10097–10105

Rao Y, Waddon AJ, Farris RJ (2001) The evolution of structure and properties in poly (p-phenylene terephthalamide) fibers. Polymer 42(13):5925–5935

Wu T-M, Blackwell J (1996) Comparison of the axial correlation lengths and paracrystalline distortion for Technora and Kevlar aromatic polyamide fibers. Macromolecules 29(17):5621–5627

Naito K (2013) Tensile properties and weibull modulus of some high-performance polymeric fibers. J Appl Polym Sci 128(2):1185–1192

Riekel C et al (1999) X-ray microdiffraction study of chain orientation in poly (p-phenylene terephthalamide). Macromolecules 32(23):7859–7865

Graham JF et al (2000) Spatially resolved nanomechanical properties of Kevlar fibers. Polymer 41(12):4761–4764

McAllister QP, Gillespie JW, VanLandingham MR (2012) Evaluation of the three-dimensional properties of Kevlar across length scales. J Mater Res 27(14):1824–1837

Sawyer LC et al (1993) The fibrillar hierarchy in liquid crystalline polymers. J Mater Sci 28(1):225–238. https://doi.org/10.1007/BF00349055

Nakamae K, Nishino T, Airu X (1992) Poisson’s ratio of the crystal lattice of poly (p-phenylene terephthalamide) by X-ray diffraction. Polymer 33(23):4898–4900

Dobb MG et al (1979) Microvoids in aramid-type fibrous polymers. Polymer 20(10):1284–1288

Dobb MG, Johnson DJ, Saville BP (1979) Structural aspects of high modulus aromatic polyamide fibres. Philos Trans R Soc Lond A: Math Phys Eng Sci 294(1411):483–485

Northolt M, Hout R (1985) Elastic extension of an oriented crystalline fibre. Polymer 26(2):310–316

Allen S (1988) Stress-coupling phenomena in anisotropic fibres. Polymer 29(6):1091–1094

Deteresa S et al (1984) Compressive and torsional behaviour of Kevlar 49 fibre. J Mater Sci 19(1):57–72. https://doi.org/10.1007/BF02403111

Knoff WF (1987) Relationship between the tensile and shear strength of aramid fibres. J Mater Sci Lett 6(12):1392–1394. https://doi.org/10.1007/BF01689299.pdf

Roche E et al (1985) Light diffraction effects from Kevlar aramid fibers. J Macromol Sci Phys 24(4):141–157

Rogozinsky A, Bazhenov S (1992) Effect of creep on the Young’s modulus of aramid fibres. Polymer 33(7):1391–1398

Beese AM et al (2014) Key factors limiting carbon nanotube yarn strength: exploring processing-structure-property relationships. ACS Nano 8(11):11454–11466

Crist B (1995) The ultimate strength and stiffness of polymers. Annu Rev Mater Sci 25(1):295–323

Young RJ et al (1992) Relationship between structure and mechanical properties for aramid fibres. J Mater Sci 27(20):5431–5440. https://doi.org/10.1007/BF00541602

Li S, McGhie A, Tang S (1994) Comparative study of the internal structures of Kevlar and spider silk by atomic force microscopy. J Vac Sci Technol A: Vac Surf Films 12(4):1891–1894

Şahin K et al (2018) Limiting role of crystalline domain orientation on the modulus and strength of aramid fibers. Polymer 140:96–106

Acknowledgements

Research was sponsored by the Army Research Laboratory and was accomplished under Cooperative Agreement Numbers W911NF-16-2-0008, W911NF-18-2-0273 and W911QX-16-D-0014. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the US Government. The US Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein. The authors would also like to acknowledge Eric Wetzel, Emil Sandoz-Rosado, and Paul Moy (US Army Research Laboratory) for helpful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

*DuPont™, and all products denoted with ® or ™ are trademarks or registered trademarks of E.I. du Pont de Nemours and Company or its affiliates.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Roenbeck, M.R., Cline, J., Wu, V. et al. Structure–property relationships of aramid fibers via X-ray scattering and atomic force microscopy. J Mater Sci 54, 6668–6683 (2019). https://doi.org/10.1007/s10853-018-03282-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-03282-x