Abstract

The accuracy of the phase fraction determined by time-of-flight neutron diffraction measurement at iMATERIA was verified by preparing model samples consisting of laminations of ferritic and austenitic stainless-steel sheets. Rietveld texture analysis, based on 132 diffractograms, was employed as the analysis method. The analyzed volume fractions of austenite agree with the prepared fractions (0.61–49.3 vol%) with a maximum error of only 5%, relative to the prepared fractions. This is due to the excellent fitting quality of the multi-diffractogram-based Rietveld refinement with consideration given to the textures of both the major and minor phases. Although the quality of the texture analysis for the austenite phase becomes poor, at <5 vol%, the consideration of the textures improves the accuracy of the phase fraction determination. Also described is how the textures affect the phase fractions, as determined by the conventional diffraction method. It is clearly shown that texture cannot be ignored in phase fraction analysis and, in turn, a reasonable consideration of the texture realizes precision in the analysis.

Similar content being viewed by others

References

Ardell J (1985) Precipitation hardening. Metall Trans A 16:2131–2165

Matsumura O, Sakuma Y, Takechi H (1992) Retained austenite in 0.4 C-Si-1.2 Mn steel sheet intercritically heated and austempered. ISIJ Int 32:1014–1020

Louzguine DV, Kato H, Louzguina LV, Inoue A (2004) High-strength binary Ti–Fe bulk alloys with enhanced ductility. J Mater Res 19:3600–3606

Ogawa Y, Ando D, Sutou Y, Koike J (2016) A lightweight shape-memory magnesium alloy. Science 353:368–370

Zhao L, Van Dijk NH, Brück E, Sietsma J, Van der Zwaag S (2001) Magnetic and X-ray diffraction measurements for the determination of retained austenite in TRIP steels. Mater Sci Eng A 313:145–152

Chen SC, Tomota Y, Shiota Y, Toomine Y, Kamiyama T (2006) Measurements of volume fraction and carbon concentration of the retained austenite by neutron diffraction. Tetsu-to-Hagané 92:557–561

Eskandari M, Zarei-Hanzaki A, Mohtadi-Bonab MA, Onuki Y, Basu R, Asghari A, Szpunar JA (2016) Grain-orientation-dependent of γ–ε–α′ transformation and twinning in a super-high-strength, high ductility austenitic Mn-steel. Mater Sci Eng A 674:514–528

Jacques PJ, Allain S, Bouaziz O, De A, Gourgues A-F, Hance BM, Houbaert Y, Huang J, Iza-Mendia A, Kruger SE, Radu M, Samek L, Speer J, Zhao L, van der Zwaag S (2009) On measurement of retained austenite in multiphase TRIP steels—results of blind round robin test involving six different techniques. Mater Sci Technol 25:567–574

Wilson AW, Madison JD, Spanos G (2001) Determining phase volume fraction in steels by electron backscattered diffraction. Scr Mater 45:1335–1340

Scarlett NVY, Madsen IC, Cranswick LMD, Lwin T, Groleau E, Stephenson G, Aylmoree M, Agron-Olshina N (2002) Outcomes of the international union of crystallography commission on powder diffraction round robin on quantitative phase analysis: samples 2, 3, 4, synthetic bauxite, natural granodiorite and pharmaceuticals. J Appl Crystallogr 35:383–400

Toraya H (2000) Estimation of statistical uncertainties in quantitative phase analysis using the Rietveld method and the whole-powder-pattern decomposition method. J Appl Crystallogr 33:1324–1328

Blondé R, Jimenez-Melero E, Zhao L, Wright JP, Brück E, Van der Zwaag S, Van Dijk NH (2012) High-energy X-ray diffraction study on the temperature-dependent mechanical stability of retained austenite in low-alloyed TRIP steels. Acta Mater 60:565–577

De Meyer M, Vanderschueren D, De Blauwe K, De Cooman BC (1999) The characterization of retained austenite in TRIP steels by X-ray diffraction. In: 41st Mechanical working and steel processing conference proceedings, pp. 483–492

De AK, Murdock DC, Mataya MC, Speer JG, Matlock DK (2004) Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr Mater 50:1445–1449

ASTM E975-13 (2013) Standard practice for X-ray determination of retained austenite in steel with near random crystallographic orientation. ASTM International, West Conshohocken. www.astm.org

Matthies S, Lutteroti L, Wenk HR (1997) Advances in texture analysis from diffraction diffractograms. J Appl Crystallogr 30:31–42

Wenk HR, Lutterotti L, Vogel S (2003) Texture analysis with the new HIPPO TOF diffractometer. Nucl Instrum Methods Phys Res Sect A 515:575–588

Kockelmann W, Chapon LC, Radaelli PG (2006) Neutron texture analysis on GEM at ISIS. Phys B 385:639–643

Keppler R, Ullemeyer K, Behrmann JH, Stipp M (2014) Potential of full pattern fit methods for the texture analysis of geological materials: implications from texture measurements at the recently upgraded neutron time-of-flight diffractometer SKAT. J Appl Crystallogr 47:1520–1534

Ishigaki T, Hoshikawa A, Yonemura M, Morishima T, Kamiyama T, Oishi R, Aizawa K, Sakuma T, Tomota Y, Arai M, Hayashi M, Ebata K, Takano Y, Komatsuzaki K, Asano H, Takano Y, Kasao T (2009) IBARAKI materials design diffractometer (iMATERIA)—versatile neutron diffractometer at J-PARC. Nucl Instrum Methods Phys Res Sect A 600:189–191

Onuki Y, Hoshikawa A, Sato S, Xu P, Ishigaki T, Saito Y, Hayashi M (2016) Rapid measurement scheme for texture in cubic metallic materials using time-of-flight neutron diffraction at iMATERIA. J Appl Crystallogr 49:1579–1584

Onuki Y, Hoshikawa A, Sato S, Ishigaki T (2017) Rapid measurement of texture of metals by time-of-flight neutron diffraction at iMATERIA and its applications. Mater Sci Forum 879:1426–1430

Lutterotti L, Chateigner D, Ferrari S, Ricote J (2004) Texture, residual stress and structural analysis of thin films using a combined X-ray analysis. Thin Solid Films 450:34–41

Young RA (1993) The rietveld method. Oxford University Press, Oxford

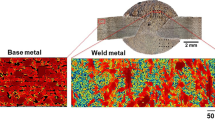

Sato H, Kamiyama T, Kiyanagi Y (2011) A Rietveld-type analysis code for pulsed neutron Bragg-edge transmission imaging and quantitative evaluation of texture and microstructure of a welded α-iron plate. Mater Trans 52:1294–1302

Shull CG, Wollan EO, Koehler WC (1951) Neutron scattering and polarization by ferromagnetic materials. Phys Rev 84:912–921

Toby BH (2006) R factors in Rietveld analyses: how good is good enough? Powder Diffr 21:67–70

Xie Y, Lutterotti L, Wenk HR, Kovacs F (2004) Texture analysis of ancient coins with TOF neutron diffraction. J Mater Sci 39:3329–3337. doi:10.1023/B:JMSC.0000026933.28906.19

Dollase WA (1986) Correction of intensities for preferred orientation in powder diffractometry: application of the March model. J Appl Crystallogr 19:267–272

Acknowledgements

The neutron diffraction experiments were conducted at the Materials and Life Science Experimental Facility of J-PARC as part of proposal 2016PM0001. The authors acknowledge the assistance of Nippon Steel Sumitomo Metal Co., Ltd., for providing the materials for the test samples. We appreciate the kind support provided by Dr. Makoto Hayashi and Dr. Tetsuro Minemura. We are also grateful to Dr. Sven Vogel for advice related to the theory and experiments. Finally, we would like to acknowledge Dr. Luca Lutterotti and his commitment to the ongoing development of the MAUD software.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Onuki, Y., Hoshikawa, A., Sato, S. et al. Quantitative phase fraction analysis of steel combined with texture analysis using time-of-flight neutron diffraction. J Mater Sci 52, 11643–11658 (2017). https://doi.org/10.1007/s10853-017-1309-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1309-x