Abstract

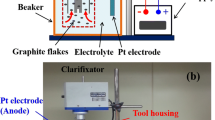

In electrochemical exfoliation, the working electrode is typically a graphite rod or foil, or highly oriented pyrolytic graphite. These electrodes are limited by the surface area that is in contact with the electrolyte and available for exfoliation. In contrast, a powder-based carbon material will have a much larger surface area exposed to the electrolyte, thus leading to an efficient exfoliation process and faster production of graphene. Herein, we have demonstrated the synthesis of few-layer graphene-like (FLG) sheets from carbon black widely available as a fine powder in its native form. It is challenging to run an electric current through a powdery material. Thus, we proposed to bind the carbon black particles together using a pH-independent intrinsically electrically conducting polymer to form a porous working electrode. Raman spectroscopy confirmed the synthesis of FLG from powder-based carbon black. The thickness of our FLG sheets was determined by atomic force microscopy to be between 3 and 8 nm. Transmission electron microscopy revealed that the sheets were ~35 nm in length and ~30 nm in width, similar to the particle size of the carbon black (~50 nm in diameter) starting material. The synthesized FLG was compared to industry standards and found to be of excellent quality. Glass coated with our FLG has a transparency of 85–90% in the 300- to 1000-nm wavelength region. The present study serves as a foundation for the electrochemical synthesis of graphene from various carbonaceous powders generated by many industries.

Similar content being viewed by others

References

Allen MJ, Tung VC, Kaner RB (2010) Honeycomb carbon: a review of graphene. Chem Rev 110:132–145. doi:10.1021/cr900070d

Novoselov KSS, Geim AKK, Morozov SVV, Jiang D, Zhang Y, Dubonos SVV, Grigorieva IVV, Firsov AAA (2004) Electric field effect in atomically thin carbon films. Science 306:666–669. doi:10.1126/science.1102896

Low CTJ, Walsh FC, Chakrabarti MH, Hashim MA, Hussain MA (2013) Electrochemical approaches to the production of graphene flakes and their potential applications. Carbon 54:1–21. doi:10.1016/j.carbon.2012.11.030

Novoselov KS, Fal′ko VI, Colombo L, Gellert PR, Schwab MG, Kim K (2012) A roadmap for graphene. Nature 490:192–200. doi:10.1038/nature11458

Coleman JN (2013) Liquid exfoliation of defect-free graphene. Acc Chem Res 46:14–22. doi:10.1021/ar300009f

Kakaei K, Hasanpour K (2014) Synthesis of graphene oxide nanosheets by electrochemical exfoliation of graphite in cetyltrimethylammonium bromide and its application for oxygen reduction. J Mater Chem A 2:15428–15436. doi:10.1039/C4TA03026E

Zhu Y, Murali S, Cai W, Li X, Suk JW, Potts JR, Ruoff RS (2010) Graphene and graphene oxide: synthesis, properties, and applications. Adv Mater 22:3906–3924. doi:10.1002/adma.201001068

Cuong TV, Pham VH, Chung JS, Shin EW, Yoo DH, Hahn SH, Huh JS, Rue GH, Kim EJ, Hur SH, Kohl PA (2010) Solution-processed ZnO-chemically converted graphene gas sensor. Mater Lett 64:2479–2482. doi:10.1016/j.matlet.2010.08.027

Han Y, Xu Z, Gao C (2013) Ultrathin graphene nanofiltration membrane for water purification. Adv Funct Mater 23:3693–3700. doi:10.1002/adfm.201202601

Miao X, Tongay S, Petterson MK, Berke K, Rinzler AG, Appleton BR, Hebard AF (2012) High efficiency graphene solar cells by chemical doping. Nano Lett 12:2745–2750. doi:10.1021/nl204414u

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191. doi:10.1038/nmat1849

Jo G, Choe M, Cho C, Kim JH, Park W, Lee S, Hong W-K, Kim T, Park S, Hong BH, Kahng YH, Lee T (2010) Large-scale patterned multi-layer graphene films as transparent conducting electrodes for GaN light-emitting diodes. Nanotechnology 21:175201. doi:10.1088/0957-4484/21/17/175201

Zurutuza A, Marinelli C (2014) Challenges and opportunities in graphene commercialization. Nat Nanotechnol 9:730–734. doi:10.1038/nnano.2014.225

Zhong YL, Tian Z, Simon GP, Li D (2015) Scalable production of graphene via wet chemistry: progress and challenges. Mater Today 18:73–78. doi:10.1016/j.mattod.2014.08.019

Zhou M, Tang J, Cheng Q, Xu G, Cui P, Qin L-C (2013) Few-layer graphene obtained by electrochemical exfoliation of graphite cathode. Chem Phys Lett 572:61–65. doi:10.1016/j.cplett.2013.04.013

Wang X, Fulvio PF, Baker GA, Veith GM, Unocic RR, Mahurin SM, Chi M, Dai S (2010) Direct exfoliation of natural graphite into micrometre size few layers graphene sheets using ionic liquids. Chem Commun 46:4487–4489. doi:10.1039/c0cc00799d

Yang W, Chen G, Shi Z, Liu C-C, Zhang L, Xie G, Cheng M, Wang D, Yang R, Shi D, Watanabe K, Taniguchi T, Yao Y, Zhang Y, Zhang G (2013) Epitaxial growth of single-domain graphene on hexagonal boron nitride. Nat Mater 12:792–797. doi:10.1038/nmat3695

Miao C, Zheng C, Liang O, Xie Y-H (2011) Chemical vapor deposition of graphene. In: Mikhailov S (ed) Physics and Applications of Graphene-Experiments. InTechOpen, Rijeka, pp 37–54. doi:10.5772/15543

Hsu C, Lin C, Huang J, Chu C, Wei K, Li L (2012) Layer-by-layer graphene/TCNQ stacked films as conducting anodes for organic solar cells. ACS Nano 6:5031–5039. doi:10.1021/nn301721q

Punith Kumar MK, Nidhi M, Srivastava C (2015) Electrochemical exfoliation of graphite to produce graphene using tetrasodium pyrophosphate. RSC Adv 5:24846–24852. doi:10.1039/C5RA01304F

Chen J, Yao B, Li C, Shi G (2013) An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 64:225–229. doi:10.1016/j.carbon.2013.07.055

Chae SJ, Güneş F, Kim KK, Kim ES, Han GH, Kim SM, Shin H, Yoon S, Choi J, Park MH, Yang CW, Pribat D, Lee YH (2009) Synthesis of large-area graphene layers on poly-nickel substrate by chemical vapor deposition: wrinkle formation. Adv Mater 21:2328–2333. doi:10.1002/adma.200803016

Bai H, Li C, Shi G (2011) Functional composite materials based on chemically converted graphene. Adv Mater 23:1089–1115. doi:10.1002/adma.201003753

Poh HL, Šaněk F, Ambrosi A, Zhao G, Sofer Z, Pumera M (2012) Graphenes prepared by staudenmaier Hofmann and Hummers methods with consequent thermal exfoliation exhibit very different electrochemical properties. Nanoscale 4:3515–3522. doi:10.1039/c2nr30490b

Rao KS, Senthilnathan J, Liu Y-F, Yoshimura M (2014) Role of peroxide ions in formation of graphene nanosheets by electrochemical exfoliation of graphite. Sci Rep 4:1–6. doi:10.1038/srep04237

Su C-Y, Lu A-Y, Xu Y, Chen F, Khlobystov AN, Li L (2011) High-quality thin graphene films from fast electrochemical exfoliation. ACS Nano 5:2332–2339. doi:10.1021/nn200025p

Van Thanh D, Li L-J, Chu C-W, Yen P-J, Wei K-H (2014) Plasma-assisted electrochemical exfoliation of graphite for rapid production of graphene sheets. RSC Adv 4:6946. doi:10.1039/c3ra46807k

Hofmann M, Chiang W, Nguy

n TD, Hsieh Y (2015) Controlling the properties of graphene produced by electrochemical exfoliation. Nanotechnology 26:335607. doi:10.1088/0957-4484/26/33/335607

n TD, Hsieh Y (2015) Controlling the properties of graphene produced by electrochemical exfoliation. Nanotechnology 26:335607. doi:10.1088/0957-4484/26/33/335607

Alaferdov AVV, Gholamipour-Shirazi A, Canesqui MAA, Danilov YA, Moshkalev SAA (2014) Size-controlled synthesis of graphite nanoflakes and multi-layer graphene by liquid phase exfoliation of natural graphite. Carbon 69:525–535. doi:10.1016/j.carbon.2013.12.062

Munuera JMM, Paredes JII, Villar-Rodil S, Ayán-Varela M, Pagán A, Aznar-Cervantes SDD, Cenis JLL, Martínez-Alonso A, Tascón JMDMD (2015) High quality, low oxygen content and biocompatible graphene nanosheets obtained by anodic exfoliation of different graphite types. Carbon 94:729–739. doi:10.1016/j.carbon.2015.07.053

Najafabadi AT, Gyenge E (2014) High-yield graphene production by electrochemical exfoliation of graphite: novel ionic liquid (IL)–acetonitrile electrolyte with low IL content. Carbon 71:58–69. doi:10.1016/j.carbon.2014.01.012

Wang G, Wang B, Park J, Wang Y, Sun B, Yao J (2009) Highly efficient and large-scale synthesis of graphene by electrolytic exfoliation. Carbon 47:3242–3246. doi:10.1016/j.carbon.2009.07.040

Wei D, Grande L, Chundi V, White R, Bower C, Andrew P, Ryhänen T (2012) Graphene from electrochemical exfoliation and its direct applications in enhanced energy storage devices. Chem Commun 48:1239. doi:10.1039/c2cc16859f

Najafabadi AT, Gyenge E (2015) Synergistic production of graphene microsheets by simultaneous anodic and cathodic electro-exfoliation of graphitic electrodes in aprotic ionic liquids. Carbon 84:449–459. doi:10.1016/j.carbon.2014.12.041

McAllister MJ, Li J, Adamson DH, Schniepp HC, Abdala AA, Liu J, Herrera-Alonso M, Milius DL, Car R, Prud’homme RK, Aksay IA (2007) Single sheet functionalized graphene by oxidation and thermal expansion of graphite. Chem Mater 19:4396–4404. doi:10.1021/cm0630800

Ramachandran R, Felix S, Joshi GM, Raghupathy BPCC, Jeong SK, Grace AN (2013) Synthesis of graphene platelets by chemical and electrochemical route. Mater Res Bull 48:3834–3842. doi:10.1016/j.materresbull.2013.05.085

Rodgers B (2015) Rubber compounding: chemistry and applications, 2nd edn. CRC Press, Boca Raton

Wang M-J, Gray CA, Reznek SA, Mahmud K, Kutsovsky Y (2003) Carbon Black. In: Kirk-Othmer Encyclopedia Chemical Technology, John Wiley & Sons, Hoboken. pp 796–798. doi:10.1002/0471238961.0301180204011414.a01.pub2

Alfè M, Gargiulo V, Di Capua R, Chiarella F, Rouzaud J, Vergara A, Ciajolo A (2012) Wet chemical method for making graphene-like films from carbon black. ACS Appl Mater Interfaces 4:4491–4498. doi:10.1021/am301197q

Wei X, Wang YZ, Long SM, Bobeczko C, Epstein AJ (1996) Synthesis and physical properties of highly sulfonated polyaniline. J Am Chem Soc 118(11):2545–2555

Wei X, Epstein AJ (1995) Synthesis of highly sulfonated polyaniline. Synth Met 74:123–125. doi:10.1016/0379-6779(95)03362-9

Ferrari AC, Meyer JC, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov KS, Roth S, Geim AK (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97:187401. doi:10.1103/PhysRevLett.97.187401

Subrahmanyam KS, Kumar P, Maitra U, Govindaraj A, Hembram KPSS, Waghmare UV, Rao CNR (2011) Chemical storage of hydrogen in few-layer graphene. Proceedings of the National Academy of Sciences 108:2674–2677. doi:10.1073/pnas.1019542108

Wang SF, Shen L, Tong YJ, Chen L, Phang IY, Lim PQ, Liu TX (2005) Biopolymer chitosan/montmorillonite nanocomposites: preparation and characterization. Polym Degrad Stab 90:123–131. doi:10.1016/j.polymdegradstab.2005.03.001

Li Y-F, Liu Y-X, Wang X-M, Wu Q-L, Yu H-P, Li J (2011) Wood-polymer composites prepared by the in situ polymerization of monomers within wood. J Appl Polym Sci 119:3207–3216. doi:10.1002/app.32837

Dey RS, Hajra S, Sahu RK, Raj CR, Panigrahi MK (2012) A rapid room temperature chemical route for the synthesis of graphene: metal-mediated reduction of graphene oxide. Chem Commun 48:1787–1789. doi:10.1039/c2cc16031e

Qi Y-X, Zhang M, Fu Q-Q, Liu R, Shi G-Y (2013) Highly sensitive and selective fluorescent detection of cerebral lead(ii) based on graphene quantum dot conjugates. Chem Commun 49:10599–10601. doi:10.1039/c3cc46059b

Guo H-L, Wang X-F, Qian Q-Y, Wang F-B, Xia X-H (2009) A green approach to the synthesis of graphene nanosheets. ACS Nano 3:2653–2659. doi:10.1021/nn900227d

Jang DM, Myung Y, Im HS, Seo YS, Cho YJ, Lee CW, Park J, Jee A-Y, Lee M (2012) Nanodiamonds as photocatalysts for reduction of water and graphene oxide. Chem Commun 48:696–698. doi:10.1039/C1CC16210A

Almeida TP, Miyazaki CM, Volpati D, Silva TA, Braunger ML, de Barros A, Hollmann F, Jr AR (2016) Ultra-thin films of reduced graphene oxide (RGO) nanoplatelets functionalized with different organic materials. J Bioprocess Biotech 6:1–5. doi:10.4172/2155-9821.1000272

Spahr ME, Rothon R (2015) Carbon black as a polymer filler. In: Palsule S (ed) Encyclopedia of Polymer Composite. Springer, Berlin, pp 1–24. doi:10.1007/978-3-642-37179-0_36-1

Ungár T, Gubicza J, Tichy G, Pantea C, Zerda TW (2005) Size and shape of crystallites and internal stresses in carbon blacks. Compos Part A Appl. Sci. Manuf 36:431–436. doi:10.1016/j.compositesa.2004.10.017

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests.

Rights and permissions

About this article

Cite this article

Sharief, S.A., Susantyoko, R.A., Alhashem, M. et al. Synthesis of few-layer graphene-like sheets from carbon-based powders via electrochemical exfoliation, using carbon black as an example. J Mater Sci 52, 11004–11013 (2017). https://doi.org/10.1007/s10853-017-1275-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1275-3

n TD, Hsieh Y (2015) Controlling the properties of graphene produced by electrochemical exfoliation. Nanotechnology 26:335607. doi:

n TD, Hsieh Y (2015) Controlling the properties of graphene produced by electrochemical exfoliation. Nanotechnology 26:335607. doi: