Abstract

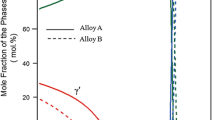

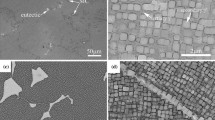

The long-term creep behavior of a Ni-based superalloy Haynes 282 at 700 and 750 °C was investigated. The creep curves exhibit the traditional shape with three creep stages. The coarsening of the γ′ phase during creep at 700 and 750 °C can be detected. The applied stress plays an important role in the coarsening of γ′ particles because of the lattice misfit and the difference of elastic modulus between the matrix and γ′ phase. Dislocation shearing into the γ′ phase and the Orowan process are the dominant creep deformation mechanisms at 700 °C/322 MPa. Dislocations tend to shearing into γ′ phase at first; nevertheless, the Orowan bowing mechanism replaces the process of shear as the coarsening of γ′ phase. The dominant deformation mechanism at 750 °C/187 MPa and 750 °C/215 MPa is dislocation gliding combined with dislocation climbing. Dislocation networks distributed in the interface of γ/γ′ phase may change the direction of dislocations and promote them to climb over the γ′ phase. The fracture surfaces were observed by scanning electron microscopy. Intergranular fracture is the dominant failure mode of the three samples because of the softening of grain boundary and stress concentration. Quasi-cleavage fracture, which are attributed to the stress concentration at the carbides/matrix interface, can be observed on the fracture surface of the specimen crept at 700 °C/322 MPa, whereas dimples with small precipitates inside can be detected on the fracture surface of the samples crept at 750 °C/187 MPa and 750 °C/215 MPa.

Similar content being viewed by others

References

Zhong ZH, Gu YF, Yuan Y, Shi Z (2013) A new wrought Ni–Fe-base superalloy for advanced ultra-supercritical power plant applications beyond 700°C. Mater Lett 109:38–41

Patel SJ, DeBarbadillo JJ, Baker BA, Gollihue RD (2013) Nickel base superalloys for next generation coal fired A-USC power plants. Proced Eng 55:246–252

Chi CY, Yu HY, Xie XS (2013) Critical high temperature materials for 700°C A-USC power plant. World Iron Steel 2:42–59

Yuan Y, Zhong ZH, Yu ZS, Yin HF et al (2015) Tensile and creep deformation of a newly developed Ni-Fe-based superalloy for 700 °C advanced ultra-supercritical boiler applications. Met Mater Int 21:659–665

Manabu T, Ryuichi K (2010) The effect of heat treatments on the creep-rupture properties of a wrought Ni-Cr heat-resistent alloy at 973 K. J Mater Sci 45:4029–4035. doi:10.1007/s10853-010-4481-9

Cabibbo M, Gariboldi E, Spigarelli S, Ripamonti D (2008) Creep behavior of INCOLOY alloy 617. J Mater Sci 43:2912–2921. doi:10.1007/s10853-007-1803-7

Pike LM (2008) Development of a fabricable gamma-prime (γ′) strengthened superalloy. TMS, Warrendale, pp 191–200

Brommesson R, Ekh M (2012) Experiments and modelling of the cyclic behaviour of Haynes 282. Tech Mech 32:130–145

Matysiak H, Zagorska M, Andersson J, Balkowiec A et al (2013) Microstructure of Haynes® 282® superalloy after vacuum induction melting and investment casting of thin-walled components. Materials 6:5016–5037

Jo CY, Jones N, Choe SJ, Knowles D (1998) High temperature mechanical properties and creep crack initiation of DS CM186LC for nozzle guide vane. Met Mater 4:1017–1025

Rozman KA, Kruzic JJ, Hawk JA (2015) Fatigue crack growth behavior of nickel-base superalloy Haynes 282 at 550–750 °C. J Mater Eng Perform 24:2841–2846

Haan J, Bezold A, Broeckmann C (2015) Interaction between particle precipitation and creep behavior in the Ni-base alloy 617B: microstructural observations and constitutive material model. Mater Sci Eng A 640:305–313

Sajjadi SA, Nategh A (2001) A high temperature deformation mechanism map for the high performance Ni-base superalloy GTD-111. Mater Sci Eng A 307:158–164

Xie J, Tian S, Shang LJ, Zhou X (2014) Creep behaviors and role of dislocation network in a powder metallurgy Ni-based superalloy during medium-temperature. Mater Sci Eng A 606:304–312

Kvapilova M, Kucharova K, Sklenicka V, Svoboda M et al (2011) Creep behaviour and microstructure changes of model cast Ni-Cr-W-C alloys. Proced Eng 10:839–844

Xie J, Tian S, Zhou X (2013) Creep properties and deformation mechanisms of a FGH95 Ni-based superalloy. J Mater Eng Perform 22:2048–2055

Unocic RR, Viswanathan GB, Sarosi PM, Karthikeyan S et al (2008) Mechanisms of creep deformation in polycrystalline Ni-base disk superalloys. Mater Sci Eng A 483–484:25–32

Viswanathan GB, Sarosi PM, Henry HM, Whitis DD et al (2005) Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT. Acta Mater 53:3041–3057

Kovarik L, Unocic RR, Li J, Sarosi P et al (2009) Microtwinning and other shearing mechanisms at intermediate temperatures in Ni-based superalloys. Prog Mater Sci 54:839–873

Karthikeyan S, Unocic RR, Sarosi PM, Viswanathan GB et al (2006) Modeling microtwinning during creep in Ni-based superalloys. Scr Mater 54:1157–1162

Tortorelli PF, Yamamoto Y, Maziase PJ, Moser JL et al (2012) Materials for advanced ultra-supercritical (A-USC) steam boilers. In: 26th Annual conference on fossil energy materials, Pittsburgh, PA

Guo JT (2007) Materials science and engineering for superalloys. Science Press Ltd, Beijing

Rettberg LH, Pollock TM (2014) Localized recrystallization during creep in nickel-based superalloys GTD444 and René N5. Acta Mater 73:287–297

Boehlert CJ, Longanbach SC (2011) A comparison of the microstructure and creep behavior of cold rolled HAYNES® 230 alloy™ and HAYNES® 282 alloy™. Mater Sci Eng A 528:4888–4898

Santella M, Shingledecker J, Swindeman B (2010) Materials for advanced ultra-supercritical steam boilers. In: 24th Annual conference on fossil energy materials, Pittsburgh, PA

Lu YL, Chen Z, Li YS, Wang YX (2006) Atomic-scale computer simulation for the coarsening mechanism of the cubic alloy including coherent strain energy. Real Met Mater Eng 35:1686–1690

Yu JJ, Sun XF, Jin T, Zhao N et al (2010) High temperature creep and low cycle fatigue of a nickel-base superalloy. Mater Sci Eng A 527:2379–2389

Vorontsov VA, Shen C, Wang Y, Dye D et al (2010) Shearing of γ′ precipitates by a 〈112〉 dislocation ribbons in Ni-base superalloys: a phase field approach. Acta Mater 58:4110–4119

Phillipsa PJ, Mills MJ (2013) Fine-scale structure of dislocations and debris in deformed Ni-based superalloy R104. Philos Mag 93:82–95

Tan LM, Zhang YW, Jia J, Han SB (2016) Precipitation of μ phase in nickel-based powder metallurgy superalloy FGH97. J Iron Steel Res Int 23:851–856

Liu YQ (2015) Study on microstructures and properties of Haynes 282 superalloy. Kunming University of Science and Technology, Kunming

Song XQ, Tang LY, Chen Z (2016) Characteristic and application of a new Ni-based superalloy Haynes 282. Mater Rev 30:116–120

Hong HU, Rho BS, Nam SW (2001) Correlation of the M23C6 precipitation morphology with grain boundary characteristics in austenitic stainless steel. Mater Sci Eng A 318:285–292

Lapin J (1999) High temperature creep of precipitation-strengthened Ni3Al-based alloy. Intermetallics 7:599–609

Ai SH, Lupinc V, Maldini M (1992) Creep fracture mechanisms in single crystal superalloys. Scr Metall Mater 26:579–584

Chen YQ, Pan SP, Liu WH, Cai ZH et al (2015) Effect of precipitates on creep behaviors of Al-Cu-Mg alloy. Chin J Nonferr Metals 25:900–909

Gabb TP, Draper SL, Hull DR, Mackay RA et al (1989) The role of interfacial dislocation networks in high-temperature creep of superalloys. Mater Sci Eng A 118:59–69

Xie J, Tian S, Shang LJ, Zhou X (2014) Creep behaviors and role of dislocation network in a powder metallurgy Ni-based superalloy during medium-temperature. Mater Sci Eng A 606:304–312

Sherry AH, Pilkington R (1993) The creep fracture of a single-crystal superalloy. Mater Sci Eng A 172:51–61

Acknowledgement

This work is financially supported by the National Natural Science Foundation of China (Grant Nos. U1361201, 51474176).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Song, X., Tang, L., Chen, Z. et al. Micro-mechanism during long-term creep of a precipitation-strengthened Ni-based superalloy. J Mater Sci 52, 4587–4598 (2017). https://doi.org/10.1007/s10853-016-0703-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0703-0