Abstract

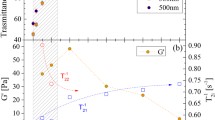

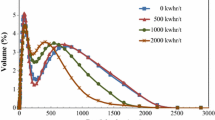

The role of surface modification on rheological properties of fibrillated cellulose suspensions has been evaluated under creep, oscillatory, and rotational testing conditions. Two types of fibrillated cellulose were produced by mechanical homogenization, followed by the deposition of poly(styrene-co-maleimide) or SMI nanoparticles containing encapsulated palm oil on the fibril surfaces. During static creep testing, the modified fibrils changed into fully viscous properties, while native fibrils showed viscoelastic behavior at low stresses. A lower viscosity and reduction in hysteresis effects were experienced during steady-state rotational flow testing, together with a reduction in yield stress after modification. A study of viscoelastic properties by oscillatory testing illustrated that the cross-over point between storage and loss moduli was shifted towards lower strains by surface modification as an indication for the enhancement of liquid-like properties observed for SMI/oil nanoparticle dispersions, while the transition point was hardly affected by fibrillation. The variations in rheological properties were overruled by surface modification and reduction in hydrogen bonding interactions of modified fibrillated cellulose, whereas rheological properties of a physical mixture of native fibrillated cellulose suspension and nanoparticle dispersion remained dominated by the fibrillated cellulose.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Herrick FW, Casebier RL, Hamilton JK, Sandberg KR (1983) Microfibrillar cellulose: morphology and accessibility. J Appl Polym Sci Polym Symp 37:797–813

Pääkkö M, Ankerfors M, Kosonen H, Nykänen A, Ahola S, Österberg M, Ruokolainen J, Laine J, Larsson PT, Ikkala O, Lindström T (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8:1934–1941

Hassan ML, Hassan EA, Oksman KN (2011) Effect of pretreatment of bagasse fibers on the properties of chitosan/microfibrillated cellulose nanocomposites. J Mater Sci 46:1732–1740. doi:10.1007/s10853-010-4992-4

Rezayati-Charani P, Dehghani-Firouzabadi M, Afra E, Blademo Å, Naderi A, Lindström T (2013) Production of microfibrillated cellulose from unbleached kraft pulp of Kenaf and Scotch Pine and its effect on the properties of hardwood kraft: microfibrillated cellulose paper. Cellulose 20:2559–2567

Bendahou A, Kaddami H, Dufresne A (2010) Investigation on the effect of cellulosic nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur Polym J 46:609–620

Nguyen HD, Mai TT, Nguyen NB, Dang TD, Le ML, Dang TT, Tran VM (2013) A novel method for preparing microfibrillated cellulose from bamboo fibers. Adv Nat Sci Nanosci Nanotechnol 4:015016–015025

Bhattacharya D, Germinario LT, Winter WT (2008) Isolation, preparation and characterization of cellulose microfibers obtained from bagasse. Carbohydr Polym 73:371–377

Kaushik A, Singh M, Verma G (2010) Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym 63:337–345

Phiriyawirut M, Chotirat N, Phromsiri S, Lohapaisarn I (2010) Preparation and properties of natural rubber-cellulose microfibril nanocomposite films. Adv Mater Res 93–94:328–331

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose—its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764

Siqueira G, Tadokoro SK, Mathew AP, Oksman K (2010) Carrot nanofibers and nanocomposites applications. In: 7th international symposium on natural polymers and composites, Gramado, Brazil

Habibi Y, Vignon MR (2007) Optimization of cellouronic acid synthesis by TEMPO-mediated oxidation of cellulose III from sugar beet pulp. Cellulose 15:177–185

Alila S, Besbas I, Vilar MR, Mutjé P, Boufi S (2013) Non-woody plants as raw materials for production of microfibrillated cellulose (MFC): a comparative study. Ind Crops Prod 41:250–259

Siro I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17:459–494

Salo T, Dimic-Misic K, Gane P, Paltakari J (2015) Application of pigmented coating colours containing MFC/NFC: coating properties and link to rheology. Nord Pulp Paper Res J 30:165–178

Nechita P, Panaitescu DM (2013) Improving the dispersibility of cellulose microfibrillated structures in a polymer matrix by controlling drying conditions and chemical surface modifications. Cell Chem Technol 47:711–719

Agoda-Tandjawa G, Durand S, Berot S, Blassel C, Gaillard C, Garnier C (2010) Rheological characterization of microfibrillated cellulose suspensions after freezing. Carbohydr Polym 80:677–686

Peng Y, Gardner DJ, Han Y (2011) Drying cellulose nanofibrils: in search of a suitable method. Cellulose 19:91–102

Missoum K, Bras J, Belgacem MN (2012) Organization of aliphatic chains grafted on nanofibrillated cellulose and influence on final properties. Cellulose 19:1957–1973

Stenstad P, Andresen M, Tanem BS, Stenius P (2008) Chemical surface modifications of microfibrillated cellulose. Cellulose 15:35–45

Huang P, Zha Y, Kuga S, Wu M, Huang Y (2016) A versatile method for producing functionalized cellulose nanofibers and their application. Nanoscale 8:3753–3759

Littunen K, Hippi U, Johansson LS, Österberg M, Tammelin T, Laine J, Seppälä J (2011) Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohydr Polym 84:1039–1047

Björkman U (2003) Break-up of suspended fibre networks. Nord Pulp Paper Res J 18:32–37

Lowys MP, Desbrieres J, Rinaudo M (2001) Rheological characterization of cellulosic microfibril suspensions: role of polymeric additives. Food Hydrocoll 15:25–32

Saarikoski E, Saarinen T, Salmela J, Seppälä J (2012) Flocculated flow of microfibrillated cellulose water suspensions: an imaging approach for characterisation of rheological behaviour. Cellulose 19:647–659

Goussé C, Chanzy H, Cerrada ML, Fleury E (2004) Surface silylation of cellulose microfibrils: preparation and rheological properties. Polymer 45:1569–1575

Karppinen A, Vesterinen AH, Saarinen T, Inen PP, Seppälä J (2011) Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 18:1381–1390

Naderi A, Lindström T (2014) Carboxymethylated nanofibrillated cellulose: effect of monovalent electrolytes on the rheological properties. Cellulose 21:3507–3514

Naderi A, Lindström T, Sundström J (2014) Carboxymethylated nanofibrillated cellulose: rheological studies. Cellulose 21:1561–1571

Missoum K, Belgacem MN, Bras J (2013) Nanofibrillated cellulose surface modification: a review. Materials 6:1745–1766

Sorvari A, Saarinen T, Haavisto S, Salmela J, Vuoriluoto M, Seppälä J (2014) Modifying the flocculation of microfibrillated cellulose suspensions by soluble polysaccharides under conditions unfavorable to adsorption. Carbohydr Polym 106:283–292

Korhonen MHJ, Sorvari A, Saarinen T, Seppälä J, Laine J (2014) Deflocculation of cellulosic suspensions with anionic high molecular weight polyelectrolytes. Bioresources 9:3550–3570

Fujisawa S, Okita Y, Fukuzumi H, Saito T, Isodai A (2011) Preparation and characterization of TEMPO-oxidized cellulose nanofibril films with free carboxyl groups. Carbohydr Polym 84:579–583

Veen SJ, Versluis P, Kuij A, Velikov KP (2015) Microstructure and rheology of microfibril-polymer networks. Soft Matter 11:8907–8912

Ahola S, Myllytie P, Österberg M, Teerinen T, Laine J (2008) Effect of polymer adsorption on cellulose nanofibril water binding capacity and aggregation. Bioresources 3:1315–1328

Rastogi VK, Stanssens D, Samyn P (2016) Reaction efficiency and retention of poly(styrene-co-maleimide) nanoparticles deposited on fibrillated cellulose surfaces. Carbohydr Polym 141:244–262

Samyn P, Van Nieuwkerke D, Schoukens G, Vonck L, Stanssens D, Van den Abbeele H (2012) Quality and statistical quantification of Brazilian vegetable oils using FTIR and Raman spectroscopy. Appl Spectrosc 66:552–565

Taheri H, Samyn P (2016) Effect of homogenization (microfluidization) process parameters in mechanical production of micro- and nanofibrillated cellulose on its rheological and morphological properties. Cellulose 23:1221–1238

Samyn P, Van Nieuwkerke D, Schoukens G, Stanssens D, Vonck L, Van den Abbeele H (2015) Hybrid palm-oil/styrene maleimide nanoparticles synthesized in aqueous dispersion under different conditions. J Microencaps 32:336–348

Saarinen T, Haavisto S, Sorvari A, Salmela J, Seppälä J (2014) The effect of wall depletion on the rheology of microfibrillated cellulose water suspensions by optical coherence tomography. Cellulose 21:1261–1275

Nechyporchuk O, Belgacem MN, Pignon F (2014) Rheological properties of micro-/nanofibrillated cellulose suspensions: wall-slip and shear banding phenomena. Carbohydr Polym 112:432–439

Samyn P, Schoukens G, Stanssens D, Vonck L, Van den Abbeele H (2015) Kaolinite nanocomposite platelets synthesized by intercalation and imidization of poly(styrene-co-maleic anhydride). Materials 8:4363–4388

Ratna T, Philipp S, Paul Q (2010) Effect of nanoparticle concentration on zeta-potential measurement results and reproducibility. Particuology 8:279–285

Liang CY, Marchessault RH (1959) Infrared spectra of crystalline polysaccharides. I. Hydrogen bonds in native celluloses. J Polym Sci 37:385–395

Fan M, Dai D, Huang B (2012) Fourier transform infrared spectroscopy for natural fibres. In: Salih MS (ed) Fourier transform—materials analysis. InTech, Crotia

Garside P, Wyeth P (2003) Identification of cellulosic fibres by FTIR spectroscopy—thread and single fibre analysis by attenuated total reflectance. Stud Conserv 4:269–274

Lee CM, Kubicki JD, Fan B, Zhong L, Jarvis MC, Kim SH (2015) Hydrogen-bonding network and OH stretch vibration of cellulose: comparison of computational modeling with polarized IR and SFG spectra. J Phys Chem B 119:15138–15149

Liang CY, Marchessault RH (1959) Infrared spectra of crystalline polysaccharides. II. Native celluloses in the region from 640 to 1700 cm−1. J Polym Sci 39:269–278

Maréchal Y, Chanzy H (2000) The hydrogen bond network in Iβ cellulose as observed by infrared spectrometry. J Mol Struct 523:183–186

Yuan L, Wan J, Ma Y, Wang Y, Huang M, Chen Y (2013) The content of different hydrogen bond models and crystal structure of eucalyptus fibers during beating. Bioresources 8:717–734

Kondo T (1997) Effect of cationic polymethacrylates on the rheology and flocculation of microfibrillated cellulose. Cellulose 4:281–292

Guo Y, Wu P (2008) Investigation of the hydrogen-bond structure of cellulose diacetate by two-dimensional infrared correlation spectroscopy. Carbohydr Polym 74:509–513

Struszcyk H (1986) Modification of lignins. III. Reaction of lignosulfonates with chlorophosphazenes. J Macromol Sci A 23:973–992

Pimentel GC, Sederholm CH (1956) Correlation of infrared stretching frequencies and hydrogen bond distances in crystals. J Chem Phys 24:639

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal lattice type. Part I. Spectra of types I, II, III and of amorphous cellulose. J Appl Polym Sci 8:1311–1324

Åkerholm M, Hinterstoisser B, Salmén L (2004) Characterization of the crystalline structure of cellulose using static and dynamic FT-IR spectroscopy. Carbohydr Res 339:569–578

Oh SY, Yoo DI, Shin Y, Kim HC, Kim HY, Chung YS, Park WH, Youk JH (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391

Janardhnan S, Sain M (2011) Targeted disruption of hydroxyl chemistry and crystallinity in natural fibers for the isolation of cellulose nanofibers via enzymatic treatment. Bioresources 6:1242–1250

Liu Y, Thibodeaux D, Gamble G (2011) Development of Fourier-transform infrared spectroscopy in direct, non-destructive, and rapid determination of cotton fiber maturity. Textile Res J 81:1559–1567

Cintron MS, Hinchliffe DJ (2015) FT-IR examination of the development of secondary cell wall in cotton fibers. Fibers 3:30–40

Taheri H, Stanssens D, Samyn P (2016) Rheological behaviour of oil-filled polymer nanoparticles in aqueous dispersion. Colloids Surf A 499:31–45

Barnes HA (2000) A handbook of elementary rheology. Institute of Non-Newtonian Fluid Mechanics, University of Wales Press (Wales), Aberystwyth

Dinand E, Chanzy H, Vignon M (1996) Parenchymal cell cellulose from sugar beet pulp: preparation and properties. Cellulose 3:183–188

Iotti M, Gregersen Ø, Moe S, Lenes M (2011) Rheological studies of microfibrillar cellulose water dispersions. J Polym Environ 19:137–145

Bröckel U, Meier W, Wagner G (2013) Product design and engineering: formulation of gels and pastes. Wiley, Heidelberg

Herschel WH, Bulkley R (1926) Konsistenzmessungen von gummi-benzollosungen. Kolloid-Z 39:291–300

Acknowledgements

This study was funded by Robert Bosch Foundation in the framework of the Juniorprofessorenprogram “Sustainable use of Natural Materials” (‘Foresnab’-Project 2011–2016) and the Juniorprofessorenprogramm Baden-Württemberg (‘NaCoPa’-Project 2012–2015). We thank Dirk Stanssens at Topchim N.V. (Wommelgem, Belgium) for assistance with surface modification reactions. We thank Dr. Ralph Thomann at Freiburger Materialforschungszentrum (FMF) for TEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Samyn, P., Taheri, H. Rheology of fibrillated cellulose suspensions after surface modification by organic nanoparticle deposits. J Mater Sci 51, 9830–9848 (2016). https://doi.org/10.1007/s10853-016-0216-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0216-x