Abstract

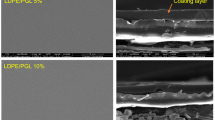

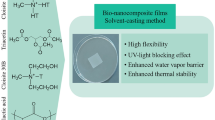

Poly(lactic acid)/poly(trimethylene carbonate) (PLA/PTMC) films incorporated with cinnamaldehyde (0, 3, 6, 9, and 12 wt%) were prepared by solvent casting and characterized by physical, mechanical, and antimicrobial properties. SEM analysis revealed that the surface of film became rougher with certain porosity when cinnamaldehyde was incorporated into the PLA/PTMC blends. Cinnamaldehyde acted as plasticizers which reduce the intermolecular forces of polymer chains, thus improving the flexibility and extensibility of the films. Differential scanning calorimetry showed that the crystallinity of PLA phase decreased by the presence of cinnamaldehyde in the composite films. Water vapor permeability of films increased with the increase of cinnamaldehyde loading. However, the active PLA/PTMC/cinnamaldehyde composite films showed adequate barrier properties for food packaging application. Incorporation of cinnamaldehyde to the PLA/PTMC polymer matrix improved the antimicrobial activity of active packaging films. These results indicated that the best compromise between mechanical, barrier, thermal, and antimicrobial properties could be achieved by the addition of 9 wt% cinnamaldehyde into PLA/PTMC blends.

Similar content being viewed by others

References

Courgneau C, Domenek S, Guinault A, Avérous L, Ducruet V (2011) Analysis of the structure–properties relationships of different multiphase systems based on plasticized poly (lactic acid). J Polym Environ 19:362–371

Persico P, Ambrogi V, Carfagna C, Cerruti P, Ferrocino I, Mauriello G (2009) Nanocomposite polymer films containing carvacrol for antimicrobial active packaging. Polym Eng Sci 49:1447–1455

Intawiwat N, Myhre E, Øysæd H, Jamtvedt SH, Pettersen MK (2012) Packaging materials with tailor made light transmission properties for food protection. Polym Eng Sci 52:2015–2024

Ambrosio-Martín J, Fabra MJ, Lopez-Rubio A, Lagaron JM (2014) An effect of lactic acid oligomers on the barrier properties of polylactide. J Mater Sci 49(8):2975–2986. doi:10.1007/s10853-013-7929-x

Hossain KMZ, Ahmed I, Parsons AJ, Scotchford CA, Walker GS, Thielemans W, Rudd CD (2012) Physico-chemical and mechanical properties of nanocomposites prepared using cellulose nanowhiskers and poly (lactic acid). J Mater Sci 47(6):2675–2686. doi:10.1007/s10853-011-6093-4

Ljungberg N, Wesslén B (2003) Tributyl citrate oligomers as plasticizers for poly (lactic acid): thermo-mechanical film properties and aging. Polymer 44:7679–7688

Burgos N, Martino VP, Jiménez A (2013) Characterization and ageing study of poly (lactic acid) films plasticized with oligomeric lactic acid. Polym Degrad Stab 98:651–658

Jamshidian M, Arab Tehrany E, Cleymand F, Leconte S, Falher T, Desobry S (2012) Effects of synthetic phenolic antioxidants on physical, structural, mechanical and barrier properties of poly lactic acid film. Carbohydr Polym 87:1763–1773

Marras SI, Zuburtikudis I, Panayiotou C (2010) Solution casting versus melt compounding: effect of fabrication route on the structure and thermal behavior of poly (l-lactic acid) clay nanocomposites. J Mater Sci 45(23):6474–6480. doi:10.1007/s10853-010-4735-6

Ljungberg N, Wesslén B (2005) Preparation and properties of plasticized poly (lactic acid) films. Biomacromolecules 6:1789–1796

Rhim JW (2013) Effect of PLA lamination on performance characteristics of agar/κ-carrageenan/clay bio-nanocomposite film. Food Res Int 51:714–722

Jain S, Reddy MM, Mohanty AK, Misra M, Ghosh AK (2010) A new biodegradable flexible composite sheet from poly (lactic acid)/poly (ε-caprolactone) blends and micro-talc. Macromol Mater Eng 295:750–762

Arrieta MP, López J, Ferrándiz S, Peltzer MA (2013) Characterization of PLA-limonene blends for food packaging applications. Polym Test 32:760–768

Qin Y, Yuan M, Li L, Guo S, Yuan M, Li W, Xue J (2006) Use of polylactic acid/polytrimethylene carbonate blends membrane to prevent postoperative adhesions. J Biomed Mater Res B 79:312–319

Qin Y, Yang J, Yuan M, Xue J, Chao J, Wu Y, Yuan M (2014) Mechanical, barrier, and thermal properties of poly(lactic acid)/poly(trimethylene carbonate)/talc composite films. J Appl Polym Sci 131:40016.1–40016.7

Hill LE, Taylor TM, Gomes C (2013) Antimicrobial efficacy of poly (dl-lactide-co-glycolide) (PLGA) nanoparticles with entrapped cinnamon bark extract against Listeria monocytogenes and Salmonella typhimurium. J Food Sci 78:626–632

Hosseini MH, Razavi SH, Mousavi MA (2009) Antimicrobial, physical and mechanical properties of chitosan-based films incorporated with thyme, clove and cinnamon essential oils. J Food Process Preserv 33:727–743

Balaguer MP, Lopez-Carballo G, Catala R, Gavara R, Hernandez-Munoz P (2013) Antifungal properties of gliadin films incorporating cinnamaldehyde and application in active food packaging of bread and cheese spread foodstuffs. Int J Food Microbiol 166:369–377

Chinma CE, Ariahu CC, Alakali JS (2013) Effect of temperature and relative humidity on the water vapour permeability and mechanical properties of cassava starch and soy protein concentrate based edible films. J Food Sci Technol. doi:10.1007/s13197-013-1227-0

Raouche S, Mauricio-Iglesias M, Peyron S, Guillard V, Gontard N (2011) Combined effect of high pressure treatment and anti-microbial bio-sourced materials on microorganisms’ growth in model food during storage. Innov Food Sci Emerg Technol 12:426–434

Sanla-Ead N, Jangchud A, Chonhenchob V, Suppakul P (2012) Antimicrobial activity of cinnamaldehyde and eugenol and their activity after incorporation into cellulose-based packaging Films. Packag Technol Sci 25:7–17

Ye H, Shen S, Xu J, Lin S, Yuan Y, Jones GS (2013) Synergistic interactions of cinnamaldehyde in combination with carvacrol against food-borne bacteria. Food Control 34:619–623

Nostro A, Scaffaro R, D’Arrigo M, Botta L, Filocamo A, Marino A, Bisignano G (2012) Study on carvacrol and cinnamaldehyde polymeric films: mechanical properties, release kinetics and antibacterial and antibiofilm activities. Appl Microbiol Biotechnol 96:1029–1038

Ouattara B, Simard RE, Piette G, Bégin A, Holley RA (2000) Inhibition of surface spoilage bacteria in processed meats by application of antimicrobial films prepared with chitosan. Int J Food Microbiol 62:139–148

Ravishankar S, Jaroni D, Zhu L, Olsen C, McHugh T, Friedman M (2012) Inactivation of Listeria monocytogenes on ham and bologna using pectin-based apple, carrot, and hibiscus edible films containing carvacrol and cinnamaldehyde. J Food Sci 77:M377–M382

Kechichian V, Ditchfield C, Veiga-Santos P, Tadini CC (2010) Natural antimicrobial ingredients incorporated in biodegradable films based on cassava starch. LWT-Food Sci Technol 43:1088–1094

Vásconez MB, Flores SK, Campos CA, Alvarado J, Gerschenson LN (2009) Antimicrobial activity and physical properties of chitosan–tapioca starch based edible films and coatings. Food Res Int 42:762–769

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocoll 27:220–227

Siripatrawan U, Harte BR (2010) Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll 24:770–775

Liu L, Jin TZ, Coffin DR, Hicks KB (2009) Preparation of antimicrobial membranes: coextrusion of poly (lactic acid) and Nisaplin in the presence of Plasticizers. J Agric Food Chem 57:8392–8398

Rhim JW, Mohanty AK, Singh SP, Ng PK (2006) Effect of the processing methods on the performance of polylactide films: thermocompression versus solvent casting. J Appl Polym Sci 101:3736–3742

Erdohan ZÖ, Çam B, Turhan KN (2013) Characterization of antimicrobial polylactic acid based films. J Food Eng 119:308–315

Fortunati E, Armentano I, Zhou Q, Iannoni A, Saino E, Visai L, Berglund LA, Kenny JM (2012) Multifunctional bionanocomposite films of poly(lactic acid), cellulose nanocrystals and silver nanoparticles. Carbohydr Polym 87:1596–1605

Ramos M, Jiménez A, Peltzer M, Garrigós MC (2012) Characterization and antimicrobial activity studies of polypropylene films with carvacrol and thymol for active packaging. J Food Eng 109:513–519

Sothornvit R, Krochta JM (2000) Oxygen permeability and mechanical properties of films from hydrolyzed whey protein. J Agric Food Chem 48:3913–3916

Guillaume C, Schwab I, Gastaldi E, Gontard N (2010) Biobased packaging for improving preservation of fresh common mushrooms (Agaricus bisporus L.). Innov Food Sci Emerg Technol 11(4):690–696

Roy S, Anantheswaran RC, Beelman RB (1996) Modified atmosphere and modified humidity packaging of fresh mushrooms. J Food Sci 61:391–397

Hwang SW, Shim JK, Selke SE, Soto-Valdez H, Matuana L, Rubino M, Auras R (2012) Poly (l-lactic acid) with added α-tocopherol and resveratrol: optical, physical, thermal and mechanical properties. Polym Int 61:418–425

Introzzi L, Fuentes-Alventosa JM, Cozzolino CA, Trabattoni S, Tavazzi S, Bianchi CL, Farris S (2012) “Wetting enhancer” pullulan coating for antifog packaging applications. ACS Appl Mater Interfaces 4:3692–3700

Zodrow KR, Schiffman JD, Elimelech M (2012) Biodegradable polymer (PLGA) coatings featuring cinnamaldehyde and carvacrol mitigate biofilm formation. Langmuir 28:13993–13999

Acknowledgements

This work was supported by the National Natural Science Foundation of China (31160198) and (31360417).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Qin, Y., Yang, J. & Xue, J. Characterization of antimicrobial poly(lactic acid)/poly(trimethylene carbonate) films with cinnamaldehyde. J Mater Sci 50, 1150–1158 (2015). https://doi.org/10.1007/s10853-014-8671-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8671-8