Abstract

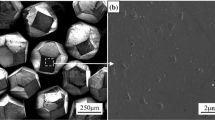

Molybdenum carbide (Mo2C) coatings on diamond particles were proposed to improve the interfacial bonding between diamond particles and copper. The Mo2C-coated diamond particles were prepared by molten salts method and the copper–diamond composites were obtained by vacuum pressure infiltration of Mo2C-coated diamond particles with pure copper. The structures of the coatings and composites were investigated using X-ray diffraction, scanning electron microscopy, and energy-dispersive X-ray spectroscopy. The results indicated that the Mo2C coatings effectively improved the wettability between diamond particles and copper matrix, and Mo2C intermediate layers were proved to decrease the interfacial thermal resistance of composites. The thermal conductivity of the composite reached 608 Wm−1 K−1 with 65 vol.% Mo2C-coated diamond, which was much higher than that with uncoated diamond. The greatly enhanced thermal conductivity is ascribed to the 1-μm-thick Mo2C coatings. Mo2C coatings on diamond particles are proved to be an effective way to enhance the thermal conductivities of copper–diamond composites.

Similar content being viewed by others

References

Feng H, Yu JK, Tan W (2010) Mater Chem Phys 124:851. doi:10.1016/j.matchemphys.2010.08.003

Weber L, Tavangar R (2007) Scr Mater 57:988. doi:10.1016/j.scriptamat.2007.08.007

Schubert T, Ciupinski L, Zielinski W, Michalski A, Weißgarber T, Kieback B (2008) Scr Mater 58:263. doi:10.1016/j.scriptamat.2007.10.011

Abyzov AM, Kidalov SV, Shakhov FM (2011) J Mater Sci 46:1424. doi:10.1007/s10853-010-4938-x

Dong YH, He XB, Xu L, Qu XH (2011) J Mater Sci 46:3862. doi:10.1007/s10853-011-5307-0

Sinha V, Spowart JE (2012) J Mater Sci. doi:10.1007/s10853-012-6878-0

Fan YM, Guo H, Xu J, Chu K, Zhu XX, Jia CC (2011) Int J Miner 18:472. doi:10.1007/s12613-011-0465-2

Schubert T, Trindade B, Weißgarber T, Kieback B (2008) Mater Sci Eng A 475:39. doi:10.1016/j.msea.2006.12.146

Ren SB, Shen XY, Guo CY, Liu N, Zang JB, He XB, Qu XH (2011) Compos Sci Technol 71:1550. doi:10.1016/j.compscitech.2011.06.012

Mayerhofer KE, Schrank C, Eisenmenger C, Hutter H (2005) Appl Surf Sci 252:266. doi:10.1016/j.apsusc.2005.02.018

Schwarz B, Schrank C, Eisenmenger C, Pollach M, Rosner M, Neubauer E (2006) Surf Coat Technol 200:4891. doi:10.1016/j.surfcoat.2005.04.042

Shao WZ, Ivanov VV, Zhen L, Cui YS, Wang Y (2004) Mater Lett 58:146. doi:10.1016/S0167-577x(03)00433-6

Chu K, Liu ZF, Jia CC, Chen H, Liang XB, Gao WJ (2010) J Alloys Compd 490:453. doi:10.1016/j.jallcom.2009.10.040

Rape A, Liu X, Kulkarni A, Singh J (2012) J Mater Sci. doi:10.1007/s10853-012-6868-2

Ekimov EA, Suetin NV, Popovich AF, Ralchenko VG (2008) Diam Relat Mater 17:838. doi:10.1016/j.diamond.2007.12.051

Balandin AA (2011) Nat Mater 10:569. doi:10.1038/nmat3064

Shamsa M, Ghosh S, Calizo I, Ralchenko V, Popovich A, Balandin AA (2008) J Appl Phys 103:083538. doi:10.1063/1.2907865

Liu WL, Shamsa M, Calizo I, Balandin AA (2006) Appl Phys Lett 89:171915. doi:10.1063/1.2364130

Yamamoto Y, Imai T, Tanabe K, Tsuno T, Kumazawa Y, Fujimori N (1997) Diam Relat Mater 6:1057. doi:10.1016/S0925-9635(96)00772-8

Yang ZH, Cai PJ, Shi L, Gu YL, Chen LY, Qian YT (2006) J Solid State Chem 179:29. doi:10.1016/j.jssc.2005.09.037

Li XK, Dong ZJ, Westwood A, Brown A, Zhang SW, Brydson R (2008) Carbon 46:305. doi:10.1016/j.carbon.2007.11.020

Zhang Y, Zhang HL, Wu JH, Wang XT (2011) Scr Mater 65:1097. doi:10.1016/j.scriptamat.2011.09.028

Xia Y, Song YQ, Lin CG, Cui S, Fang ZZ (2009) Trans Nonferr Met Soc 19:1161. doi:10.1016/S1003-6326(08)60422-7

Hasselman DPH, Lloyd FJ (1987) J Compos Mater 21:508. doi:10.1177/002199838702100602

Swartz ET, Pohl RO (1989) Rev Mod Phys 61:605. doi:10.1103/RevModPhys.61.605

Goyal V, Subrina S, Nika DL, Balandin AA (2010) Appl Phys Lett 97: 031904. doi:10.1063/1.3463455

Yan Z, Liu GX, Khan JM, Balandin AA (2012) Nat Commun 3:827. doi:10.1038/ncomms1828

Yu J, Liu GX, Sumant AV, Goyal V, Balandin AA (2012) Nano Lett 12:1603. doi:10.1021/nl204545q

Every AG, Tzou Y, Hasselman DPH, Raj R (1992) Acta Metall Mater 40:123. doi:10.1016/0956-7151(92)90205-S

Hopkins PE, Beechem TE (2010) Nanoscale Microscale Thermophys Eng 14:51. doi:10.1080/15567261003601805

Prasher RS, Phelan PE (2001) J Heat Transfer 123:105. doi:10.1115/1.1338138

Hopkins PE, Kassebaum JL, Norris PM (2009 J Appl Phys. doi:10.1063/1.3068476

Majumdar A, Reddy P (2004) Appl Phys Lett 84:4768. doi:10.1063/1.1758301

Hopkins PE, Norris PM, Stevens RJ, Beechem TE, Graham S (2008) J Heat Transfer. doi:10.1115/1.2897344

Acknowledgements

This work was financially supported by “the Fundamental Research Funds for the Central Universities (FRF-TP-10-003B)” and “the National Natural Science Foundation of China (Grant No. 51274040).”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kang, Q., He, X., Ren, S. et al. Preparation of high thermal conductivity copper–diamond composites using molybdenum carbide-coated diamond particles. J Mater Sci 48, 6133–6140 (2013). https://doi.org/10.1007/s10853-013-7409-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7409-3