Abstract

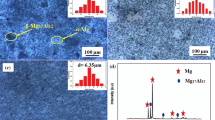

Ultrafine-grained (UFG) Al-26 wt% Si alloy was obtained through multipass equal-channel angular pressing (EACP) procedure and subsequently tested in 3.5 wt% NaCl solution for the evaluation of electrochemical corrosion. The results show that the ECAPed alloy with increased number of pressing passes obtain lower mass-loss ratios, nobler E corr and E pit, lower I corr values, and higher anode polarization. The improved corrosion resistance of the ECAPed alloy results from the homogeneous UFG structure with the breakage of brittle large primary silicon crystals, which contributes to a higher pitting resistance. The oxidation product with improved adhesion force and protection efficacy can be formed with greater ease on UFG alloys. It implies that grain refinement through severe-plastic-deformation can enhance anticorrosion behavior of hypereutectic Al–Si alloys, besides the well-known strengthening and toughening effects.

Similar content being viewed by others

References

Hwang B, Lee S, Kim YC et al (2006) Mater Sci Eng A 441(1–2):308

Jiang JF, Luo SJ (2007) Trans Nonferrous Met Soc China 16(6):1313

Sitdikov O, Sakai T, Avtokratova E et al (2007) Mater Sci Eng A 444(1–2):18

Vinogradov A, Patlan V, Suzuki Y et al (2002) Acta Mater 50(7):1639

Vinogradov A, Hashimoto S, Kopylov VI (2003) Mater Sci Eng A 355(1–2):277

Stolyarov VV, Zhu YT, Alexandrov IV et al (2003) Mater Sci Eng A 343(1–2):43

Stolyarov VV, Gunderov DV, Popov AG et al (2002) J Magn Magn Mater 242–245:1399

Kawasaki M, Sklenička V, Langdon TG (2010) J Mater Sci 45(1):271. doi:10.1007/s10853-009-3975-9

Kim WJ, Hyun CY, Kim HK (2006) Scr Mater 54:1745

Lee S (2008) J Mater Process Technol 201(1–3):441

Yamasaki T, Miyamoto H, Mimaki T et al (2001) Mater Sci Eng A 318:122

Vinogradov A, Mimaki T, Hashimoto S et al (1999) Scr Mater 41:319

Balyanov A, Kutnyakova J, Amirkhanova NA et al (2004) Scr Mater 51(3):225

Chung MK, Choi YS, Kim JG et al (2004) Mater Sci Eng A 366(2):282

Zeiger W, Schneider M, Scharnweber D et al (1995) Nanostruct Mater 6:1013

Chen ZH, Kang ZT (2000) J Central South Univ Technol 7(3):133

Shibata S, Tomita S, Nakata K (2000) J Japan Inst Light Met 50:609

Bendijk A, Delhez R, Katgerman L et al (1980) J Mater Sci 15(11):2803. doi:10.1007/BF00550549

Ma AB, Suzuki K, Saito N et al (2005) Mater Sci Eng A 399:181

Zhao YH, Liao XZ, Jin Z et al (2004) Acta Mater 52(15):4589

Kim JK, Kim HK, Park JW et al (2005) Scr Mater 53(10):1207

Jiang JH, Ma AB, Lu FM et al (2011) Mater Corros 62(9):848

Narayanan LA, Samuel FH, Gruzleski JE (1994) Metall Mater Trans A 25:1761

Cui C, Schulz A, Epp J et al (2010) J Mater Sci 45(10):2798. doi:10.1007/s10853-010-4269-y

Stolyarov VV, Zhu YT, Alexandrov IV et al (2001) Mater Sci Eng A 299(1–2):59

Stupnišek-Lisac E, Podbršček S, Sorić T (1994) J Appl Electrochem 24:779

Amin MA (2009) Electrochim Acta 54(6):1857

Foley RT (1986) Corrosion 42(5):277

Seri O, Furumata K (2006) Mater Corros 51:111

Acknowledgements

This study was supported by National Natural Science Foundation of China (Grant No. 51141002) and the Fundamental Research Funds for the Central Universities (Hohai University No. 2009B15314).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, J., Ma, A., Song, D. et al. Anticorrosion behavior of ultrafine-grained Al-26 wt% Si alloy fabricated by ECAP. J Mater Sci 47, 7744–7750 (2012). https://doi.org/10.1007/s10853-012-6703-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6703-9