Abstract

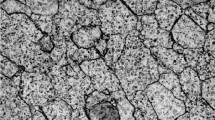

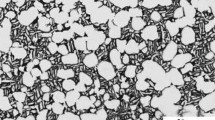

Interrupted compression tests of TA15 titanium alloy with initially equiaxed microstructure were carried out at deformation temperatures between 1173 to 1273 K and strain rates between 0.001 to 0.1 s−1 to investigate the deformation behavior and microstructure evolution under multistage deformation. The TA15 alloy exhibits significant flow softening in both β and (α + β) working. It is found that the flow softening relates to dynamic recrystallization of β phases under current experimental conditions. In multistage β working, metadynamic recrystallization is the main softening mechanism during inter-pass holding. The grain refinement by metadynamic recrystallization leads to the decrease in peak stress upon reloading. In multistage (α + β) working, static recrystallization is the main softening mechanism during inter-pass holding. The static recrystallization kinetics increases with temperature and strain rate. The inter-pass holding has little influence on the morphology of the primary α phases. The β grain size is determined by spacing of primary α phases, which is more affected by working temperature but less dependent on strain rate and inter-pass holding time.

Similar content being viewed by others

References

Vo P, Jahazi M, Yue S (2008) Metall Mater Trans A 39:2965

Liu Y, Zhu J, Wang Y, Zhan J (2008) Mater Sci Eng A 490:113

Sun ZC, Yang H, Han GJ, Fan XG (2010) Mater Sci Eng A 527:3464

Lin YC, Chen MS, Zhong J (2009) J Mater Process Technol 209:2477

Lin YC, Chen MS (2009) Mater Sci Eng A 501:229

Weaver DS, Semiatin SL (2007) Scripta Mater 57:1044

Beer AG, Barnett MR (2009) Scripta Mater 61:1097

Sheppard T, Norley J (1988) Mater Sci Technol 4:903

Ding R, Guo ZX (2004) Mater Sci Eng A 365:172

Ma F, Lu W, Qin J, Zhang D (2006) Mater Sci Eng A 416:59

Jackson M, Dashwood R, Christodoulou L, Flower H (2005) Metall Mater Trans A 36:1317

Zong YY, Shan DB, Xu M, Lv Y (2009) J Mater Process Technol 209:1988.

Zong YY, Shan DB, Lu Y (2006) J Mater Sci 41:3753. doi:https://doi.org/10.1007/s10853-006-2658-z

Wanjara P, Jahazi M, Monajati H, Yue S, Immarigeon JP (2005) Mater Sci Eng A 396:50

Huang LJ, Geng L, Li AB, Cui XP, Li HZ, Wang GS (2009) Mater Sci Eng A 505:136

Furuhara T, Poorganji B, Abe H, Maki T (2007) JOM 59:64

Ding R, Guo ZX, Wilson A (2002) Mater Sci Eng A 327:233

Semiatin SL, Montheillet F, Shen G, Jonas JJ (2002) Metall Mater Trans A 33:2719

Vo P, Jahazi M, Yue S, Bocher P (2007) Mater Sci Eng A 447:99

Weiss I, Semiatin SL (1999) Mater Sci Eng A 263:243

Luo J, Li M, Li H, Yu W (2009) Mater Sci Eng A 505:88

Niu Y, Hou H, Li M, Li Z (2008) Mater Sci Eng A 492:24

Momeni A, Abbasi SM (2010) Mater Design 31:3599

Li MQ, Pan HS, Lin YY, Luo J (2007) J Mater Process Technol 183:71

Briottet L, Jonas JJ, Montheillet F (1996) Acta Mater 44:1665

Philippart I, Rack HJ (1998) Mater Sci Eng A 243:196

Blaz L, Sakai T, Jonus JJ (1983) Metal Sci 17:609

Kugluer G, Turk R (2004) Acta Mater 52:4659

Fernández AI, López B, Rodriguez-Ibabe JM (1999) Scripta Mater 40:543

Hunphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Pergamon Press, Oxford

Nes E, Ryum N, Hunderi O (1985) Acta Metall 33:11

Stefansson N, Semiatin SL (2003) Metall Mater Trans A 34:691

Semiatin SL, Kirby BC, Salishchev GA (2004) Metall Mater Trans A 35:2809

Sakai T, Jonas JJ (1984) Acta Metall 32:189

Acknowledgements

The authors would like to gratefully acknowledge the support of Natural Science Foundation for Key Program of China (No. 50935007) and National Basic Research Program of China (No. 2010CB731701).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fan, X.G., Yang, H. & Gao, P.F. Deformation behavior and microstructure evolution in multistage hot working of TA15 titanium alloy: on the role of recrystallization. J Mater Sci 46, 6018–6028 (2011). https://doi.org/10.1007/s10853-011-5564-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5564-y