Abstract

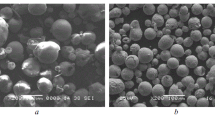

The formation of the nanostructured WC–10 wt% Co powder from WO3, Co3O4, and graphite is studied. The effects of the processing parameters of high-energy ball milling, reduction in H2 atmosphere, and carburization in Ar/CO atmosphere are investigated. The crystallite size of the as-synthesized WC is 30–40 and 40–50 nm for 900 and 1000 °C carburized powders, respectively. The powder is agglomerated with the size of the primary particles ranging from 50 to 700 nm. High-energy ball milling of WO3–Co3O4–C powder mixtures leads to finer particle and crystallite sizes with larger surface area. Such milled powders can be reduced to nanostructured W at 570 °C and carburized to form WC at temperatures as low as 900 °C. Crystal growth has taken place during carburization, particularly at 1000 °C, which results in the formation of truncated triangular prisms and nanoplates of WC at 1000 °C.

Similar content being viewed by others

References

Gleiter H (1992) Nanostruct Mater 1:1

Fang Z, Wang X, Ryu T, Hwang K, Sohn H (2009) Int J Refract Metals Hard Mater 27:288

Porat R, Berger S, Rosen A (1996) Mater Sci Forum 629:225

Fecht HJ (1992) Nanostruct Mater 1:125

Fecht HJ, Hellstern E, Fu Z, Johnson WL (1990) Metall Mater Trans A 21:2333

Gao L, Kear BH, Seegopaul P (1999) US Patent 5,919,428

Seegopaul P, Gao L (2003) US Patent 6,524,366

Kim BK, Ha GG, Woo Y (2003) US Patent 6,511,551

Lee G, Ha GH, Kim BK (1999) J Korean Inst Metal Mater 37:1233

Zhang ZY, Wahlberg S, Wang MS, Muhammed M (1999) Nanostruct Mater 12:163

Ryu T, Sohn HY, Han G, Kim Y, Hwang KS, Mena M, Fang ZZ (2008) Metall Mater Trans B 39:1

Hojo J, Oku T, Kato A (1978) J Less-Common Metal 59:85

Fitzsimmons M, Sarin VK (1995) Surf Coat Technol 76:250

Kim JC, Kim BK (2004) Scripta Mater 50:969

Ban ZG, Shaw L (2002) J Mater Sci 37:3397. doi:10.1023/A:1016553426227

Ban ZG, Shaw L (2001) Acta Mater 49:2933

Yang ZG, Shaw L (1996) Nanostruct Mater 7:873

Zhong Y, Shaw L, Manjarres M, Zawrah MM (2010) J Am Ceram Soc 93:3159

Klug HP, Aexander LE (1974) X-ray diffraction procedures for polycrystalline and amorphous materials. Wiley, New York

Snyder RL, Fiala J, Bunge HJ (1999) Defect and microstructure analysis by diffraction. Oxford University Press, Oxford

Mittermeijer EJ, Scardi P (2004) Diffraction analysis of the microstructure of materials. Springer-Verlag, Berlin

Ungar T (2004) Scripta Mater 51:777

Liu W, Song X, Zhang J, Zhang G, Liu X (2008) Mater Chem Phys 109:235

Aronsson B, Pastor H (1991) Powder metallurgy: an overview. The Institute of Metals, London

Binnewies M, Milke E (2002) Thermochemical data of elements and compounds, 2nd edn. Wiley-VCH, Weinheim

Yih S, Wang C (1979) Tungsten: source metallurgy properties and applications. Plenum Press, New York, p 385

Gu D, Shen Y (2006) Mater Lett 60:3664

de Villiers HL (1998) J Therm Spray Technol 7:357

Sahraoui T, Guessasma S, Ali Jeridane M, Hadji M (2010) Mater Design 31:1431

Exner HE (1979) Int Mater Rev 24:149

French DN, Thomas DA (1968) In: Vahldiek FV, Mersol J (eds) Anisotropy in single-crystal refractory compounds, vol 1. Plenum Press, New York

Takahashi T, Freise EJ (1965) Philos Mag 12:1

Acknowledgements

This research was sponsored by the U.S. National Science Foundation (NSF) under the contract number CMMI-0856122. The support and vision of Dr. Mary Toney is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhong, Y., Shaw, L. A study on the synthesis of nanostructured WC–10 wt% Co particles from WO3, Co3O4, and graphite. J Mater Sci 46, 6323–6331 (2011). https://doi.org/10.1007/s10853-010-4937-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4937-y