Abstract

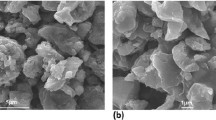

In this study, 2618 aluminum alloy metal matrix composites (MMCs) reinforced with two different sizes and weight fractions of SiCp particles upto 10% weight were fabricated by stir cast method and subsequent forging operation. The effects of SiCp particle content and size of the particles on the mechanical properties of the composites such as hardness, tensile strength, hot tensile strength (at 120 °C), and impact strength were investigated. The density measurements showed that the samples contained little porosity with increasing weight fraction. Optical microscopic observations of the microstructures revealed uniform distribution of particles and at some locations agglomeration of particles and porosity. The results show that hardness and tensile strength of the composites increased, with decreasing size and increasing weight fraction of the particles. The hardness and tensile strength of the forged composites were higher than those of the cast samples.

Similar content being viewed by others

References

Surappa MK, Rohatgi RK (1981) J Mater Sci 16:983

Hanumanth GS, Iron GA (1993) J Mater Sci 28:2459

Sahin Y, Murphy S (2014) J Mater Sci 34(1996):5399

Papazian JM, Adler PN (1990) Metall Trans 21A:401

Carcalho MH, Marcelo T, Carvalhinos H, Cellars CM (1992) J Mater Sci 27:2101

Ceschini L, Minak G, Morri A (2006) Compos Sci Technol 66:333

Shorowordi KM, Laoui T, Hasseb ASMA, Celis JP, Froyen L (2003) J Mater Process Technol 142:738

Srivatsan TS, Al-Hajri M (2002) Compos Part B 33:391

Gibson PR, Clegg AJ, Das AA (1985) Mater Sci Technol 1:558

Dellis MA, Keastenmans JP, Dellanay F (1991) Materi Sci Eng 135A:253

Rohatgi PK (1991) J Metals 43(4):10

Kocazac MJ, Khatri SC, Allison JE, Bader MG et al (1993) In: Suresh S et al (eds) Fundamentals of metal matrix composites, Butterworths, Guildford, UK, p 267

Srivatsan TS, Ibrahim IA, Mohamed FA, Lavernia EJ (1991) J Mater Sci 26:5965

Sahin Y, Kok M, Celik H (2002) J Mater Process Technol 128:280

Taha MA, El-Mahallawy NA (1998) J Mater Process Technol 73:139

Delannay F, Froyan L, Deruyttere A (1987) J Mater Sci 22:1

Seo YH, Kang CG (1985) J Mater Process Technol 55:370

Davidson AM, Regener D (2000) Compos Sci Technol 60:865

Rohatgi PK, Sathyamoorthy R, Narendranath CS, Nath D (1993) AFS Trans 101:597

Tszeng TC (1998) Compos: Part B 29B:299

Girot FA, Quenisset JM, Naslain R (1987) Compos Sci Technol 30:155

Lianxi H, Shoujing L, Wencan H, Wang ZR (1995) J Mater Process Technol 49:287

Cavaliere P, Cerri E, Evangelista E (2004) J Alloy Compd 378(1–2):117

Xu H, Palmiere EJ (1999) Compos Part A 30:203

Thomas MP, King JE (1996) Compos Sci Technol 56:1141

Kok M (2005) J Mater Process Technol 161:381

Harnby N, Edward MF, Nienow AW (1985) Mixing in process industries. Butterworths, London

Hashim J, Looney L, Hashmi MSJ (1999) J Mater Process Technol 92–93:1

Naher S, Brabazon D, Looney L (2003) J Mater Process Technol 143–144:567

Hashim J, Looney L, Hashmi MSJ (2002) J Mater Process Technol 123:258

Ozden S, Ekici R, Nair F (2007) Compos Part A 38(2):484

Acknowledgement

The authors wish to express gratitude to HAL (Hindustan Aeronautics Limited), Bangalore, India for providing the facilities to carry out experiments, pertaining to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakthivel, A., Palaninathan, R., Velmurugan, R. et al. Production and mechanical properties of SiCp particle-reinforced 2618 aluminum alloy composites. J Mater Sci 43, 7047–7056 (2008). https://doi.org/10.1007/s10853-008-3033-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3033-z