Abstract

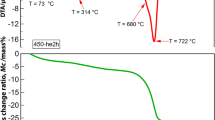

The present paper discusses different processing technologies for fabrication of novel 45S5 Bioglass®-derived glass–ceramic scaffolds with tailored porosity gradient for potential application in bone tissue engineering. Different types of scaffolds with continuous or stepwise gradient of porosity were produced by the foam replication technique, using preformed polyurethane (PU) foams as sacrificial templates. After preforming the PU foams in metallic moulds, they were dipped in a 45S5 Bioglass®-based slurry and subsequently heat treated in a chamber furnace up to 1100 °C. During heating, the organic phase is burned out and the glass sinters and partially crystallises. By using this new approach, Bioglass®-derived glass-ceramic scaffolds with different shapes and porosity profiles were designed. Scanning electron microscopy (SEM) showed that all samples have highly interconnected porous structure, with specific porosity gradients. By modifying the shape and dimensions of the metallic mould, bioactive glass–ceramic scaffolds with complex shapes and different degrees of porosity gradient could be obtained.

Similar content being viewed by others

References

Martin I, Miot S, Barbero A, Jakob M, Wendt D (2007) J Biomech 40(4):750

Roether JA, Boccaccini AR, Hench LL, Maquet V, Gautier S, Jérôme R (2002) Biomaterials 23:3871

Karageorgiou V, Kaplan D (2005) Biomaterials 26(27):5474

Logeart-Avramoglou D, Anagnostou F, Bizios R et al (2005) J Cell Mol Med 9(1):72

Rezwan K, Chen QZ, Blaker JJ, Boccaccini AR (2006) Biomaterials 27:3413

Pompe W, Worch H, Epple M et al (2003) Mater Sci Eng A362:40

Suresh S, Mortensen A (1998) Fundamentals of functionally graded materials: processing and thermomechanical behaviour of graded metals and metal-ceramic composites. The University Press, Cambridge

Harley BA et al (2006) Biomaterials 27:866

Ghosh S, Viana JC, Reis RL et al (2006) Key Eng Mater 309–311:1109

Sherwood JK, Riley SL, Palazzolo R et al (2002) Biomaterials 23:4739

Oliveira JM, Rodrigues MT, Silva SS et al (2006) Biomaterials 27:6123

Hench LL (1998) J Am Ceram Soc 81:1705

Chichoki FR, Trumble KP (1998) J Am Ceram Soc 81:1661

Chung TJ, Neubrand A, Roedel J (2002) Key Eng Mater 206–213:965

Chen QZ, Thompson ID, Boccaccini AR (2006) Biomaterials 27:2414

Acknowledgements

This work was funded with support of the EU Marie Curie fellowship scheme (Grant MEIF-CT-2005-024248).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bretcanu, O., Samaille, C. & Boccaccini, A.R. Simple methods to fabricate Bioglass®-derived glass–ceramic scaffolds exhibiting porosity gradient. J Mater Sci 43, 4127–4134 (2008). https://doi.org/10.1007/s10853-008-2536-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2536-y