Abstract

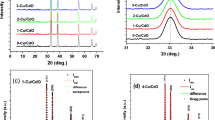

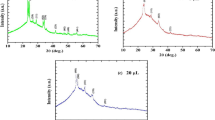

The results of structural characterization of SnO2 films doped by impurities such as Fe, Cu, Ni, and Co during spray pyrolysis deposition from 0.2 M SnCl4–water solutions are presented. The change of parameters such as film morphology, the grain size, texture, and the intensity of X-ray diffraction peaks were controlled. For structural analysis of tested films, we used X-ray Diffraction, Scanning Electron Microscopy, and Atomic Force Microscopy techniques. It was shown that the doping promoted the change of the film morphology and the decrease of the SnO2 grain size; however, these changes were not great. The doping influence becomes apparent more obviously for thin films and the films deposited at low temperatures (T pyr ∼ 350 °C). At higher pyrolysis temperatures (T pyr ∼ 450 °C), the influence of the doping on both the grain size and the film morphology was weakened. We concluded that used additives had dominant influence on the structural properties of SnO2 at the initial stages of the film growth, as well as at the stages of twinning and agglomeration of the SnO2 crystallites. It was shown that the increase in the contents of the fine dispersion phase in as-deposited film is an important consequence of the SnO2 doping.

Similar content being viewed by others

References

Gopel W, Hese J, Zemel JN (eds) (1991) Sensors: a comprehensive survey. Chemical and biochemical sensors, part 1, vol 2. VCH, Germany

Gopel W, Scherbaum KD (1995) Sens Actuators B 26–27:1

Morrison SR (1986) In: Aucouturier JL (ed) Proceedings of the 2nd international meeting on chemical sensors, Bourdeaux, France, 7–10 July, p 39

Moseley PT, Tofield BC (eds) (1987) Solid state gas sensors. Adam Hilgen, Bristol

Korotcenkov G (2005) Sens Actuators B 107:209

Korotcenkov G (2007) Mater Sci Eng B 139:1

Choi SD, Lee DD (2001) Sens Actuators B 77:335

Ivanovskaya M, Bogdanov P, Faglia G, Nelli P, Sberveglieri G, Taroni A (2001) Sens Actuators B 77:268

Ferroni M, Carotta MC, Guidi V, Martinelli G, Ronconi F, Sacerdoti M, Traversa E (2001) Sens Actuators B 77:163

Madou MJ, Morrison SR (1989) Chemical sensing with solid state devices. Academic Press, Inc., San Diego

McAleer JF, Moseley PT, Norris JOW, Williams DE, Tofield BC (1988) J Chem Soc Faraday Trans 1 84:441

Meixner H, Lampe U (1996) Sens Actuators B 37:198

Yamazoe N, Miura N (1992) In: Yamauchi N (ed) Chemical sensors technology, vol 4. Kodansha, Tokyo, pp 20–41

Yamazoe N, Kurokawa Y, Seiyama T (1983) Sens Actuators 4:283

Wang JF, Chen HC, Su WB, Zang GZ, Wang B, Gao RW (2006) J Alloy Compd 413:35

Qi P, Wang JF, Su WB, Chen HC, Zang GZ, Wang CM, Ming BQ (2005) Mater Chem Phys 92:578

Gleiter H (1992) Nanostruct Mater 1:1

Gleiter H (2000) Acta Mater 48:1

Kanazawa E, Sakai G, Shimanoe K, Kanmura Y, Teraoka Y, Miura N, Yamazoe N (2001) Sens Actuators B 77:72

Shimizu Y, Matsunaga N, Hyodo T, Egashira M (2001) Sens Actuators B 77:35

Skala T, Veltruska K, Moroseac M, Matolinova I, Korotcenkov G, Matolin V (2003) Appl Surf Sci 205:196

Szezuko D, Werner J, Oswald S, Behr G, Wetzing K (2001) Appl Surf Sci 179:301

Wang W, Xu C, Wang X, Liu Y, Zhan Y, Zheng C, Song F, Wang G (2002) J Mater Chem 12:1922

Yamaura H, Jinkawa T, Tamaki J, Moriya K, Miura N, Yamazoe N (1996) Sens Actuators B 35–36:325

Yamaura H, Moriya K, Miura N, Yamazoe N (2000) Sens Actuators B 65:39

Korotcenkov G, Boris I, Brinzari V, Luchkovsky Y, Karkotsky G, Golovanov V, Cornet A, Rossinyol E, Rodriguez J, Cirera A (2004) Sens Actuators B 103:13

Carreno NLV, Maciel AP, Leite ER, Lisboa-Filho PN, Longo E, Valentino A, Probst LED, Paiva-Santos CO, Schreiner WH (2002) Sens Actuators B 86:185

Kawamura F, Takahashi T, Yasui I, Sunagawa I (2001) J Cryst Growth 233:259

Palatnik LS, Fuks MI, Kosevich VM (1972) Mechanism of formation and substructure of condensed films. Nauka, Moscow (in Russian)

Panchapakesan B, De Voe DL, Widmaier MR, Cavicchi R, Semancik S (2001) Nanotechnology 12:336

Kawamura F, Yasui I, Sunagawa I (2001) J Cryst Growth 233:517

Hong NH (2006) J Magn Magn Mater 303:328

Yan L, Pan JS, Ong CK (2006) Mater Sci Eng B 128:34

Rodriguez-Torres CE, Fabiana Cabrera A, Sanchez FH (2007) Phys B: Condens Mater 389:176

Korotcenkov G, Cornet A, Rossinyol E, Arbiol J, Brinzari V, Blinov Y (2005) Thin Solid Films 471:310

Korotcenkov G, Brinzari V, Dibattista M, Schwank J, Vasiliev A (2001) Sens Actuators B 77:244

Brinzari V, Korotcenkov G, Schwank J, Lantto V, Saukko S, Golovanov V (2002) Thin Solid Films 408:51

Korotcenkov G, Brinzari V, Schwank J, Cerneavschi A (2001) Mater Sci Eng C 19:73

Korotcenkov G, Dibattista M, Schwank J, Brinzari V (2000) Mater Sci Eng B 77:33

Pagnier T, Boulova M, Galerie A, Gaskov A, Lucazeau G (2001) Sens Actuators B 71:134

Dufour LC, Nowotny J (eds) (1988) Surface and near-surface chemistry of oxide materials. Elsevier, Amsterdam

Nowotny J (1988) Solid State Ionics 28–30:1235

Kim BC, Jung JI, Lee JH, Kim JJ (2001) Solid State Ionics 144:321

Liu CM, Fang LM, Zu XT, Zhou WL (2007) Chin Phys Soc (IOP) 16:95

Chimbeu CM, Van Landschoot RC, Schoonman J, Lumbreras M (2007) J Eur Ceram Soc 27:207

Varela JA, Cerri JA, Leite ER, Longo E, Shamsuzzoha M, Bradt RC (1999) Ceram Int 25:253

Korotcenkov G, Blinov I, Ivanov M, Stetter JR (2007) Sens Actuators B 120:679

Korotcenkov G, Brinzari V, Dmitriev S (1999) Sens Actuators B 54:202

Thompson CV (2000) Annu Rev Mater Sci 30:159

Jimenez VM, Espinos JP, Caballero A, Contreras L, Fernandez A, Justo A, Gonzalez-Elope AR (1999) Thin Solid Films 353:113

Korotcenkov G, Cerneavschi A, Brinzari V, Cornet A, Morante J, Cabot A, Arbiol J (2002) Sens Actuators B 84:37

Pan X, Zheng JG (1997) In: Im J, Yalisove S, Adams B, Zhu Y, Chen F-R (eds) Polycrystalline thin films-structure, texture, properties and applications III, MRS symposium proceedings, vol 472. Boston, USA, p 87

Korotcenkov G, Macsanov V, Tolstoy V, Brinzari V, Schwank J, Faglia G (2003) Sens Actuators B 96:602

Acknowledgements

This work was supported by Supreme Council of Science and Advanced Technology of the Republic of Moldova in the frame of special State Program. Authors are thankful also to Prof. J. Schwank for helping in XRD and SEM characterization of studied samples. G. Korotcenkov is thankful to Korean Brain Pool Program for the support to his research as well.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Korotcenkov, G., Brinzari, V. & Boris, I. (Cu, Fe, Co, or Ni)-doped tin dioxide films deposited by spray pyrolysis: doping influence on film morphology. J Mater Sci 43, 2761–2770 (2008). https://doi.org/10.1007/s10853-008-2486-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2486-4