Abstract

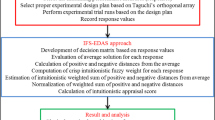

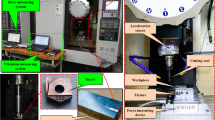

The present work deals with multi-responses optimization of ultrasonic machining process using the imperialist competitive algorithm (ICA). Here, the process inputs were tool material, grit size and power rating of ultrasonic horn. Also, the main responses which should be simultaneously optimized were material removal rate (MRR), tool wear rate (TWR) and surface roughness (SR). Firstly, numbers of 24 experiments were conducted to collect data according to full factorial design. Then, obtained data were used to develop mapping relationship between inputs and responses based on adaptive neuro-fuzzy inference system (ANFIS). In order to maximize the MRR and minimize the TWR and SR simultaneously, the developed ANFIS models of MRR, TWR and SR were associated with ICA. Results indicated that the titanium tool, grit size of 423 and power rating of 328 W are the optimal solution which caused MRR of \(0.85\, \hbox {mg}/\hbox {min}\), TWR of \(0.22\,\hbox {mg}/\hbox {min}\) and SR of \(0.65\,\upmu \hbox {m}\). Therefore, the ANFIS-ICA is a potential method which can be applied for optimization of multi-responses manufacturing problems in which characteristics are highly correlated to each other.

Similar content being viewed by others

References

Atashpaz-Gargari, E., & Lucas, C. (2007). Imperialist competitive algorithm: an algorithm for optimization inspired by imperialistic competition . In IEEE Congress on Evolutionary Computation (pp. 4661–4667).

Babajanzade-Roshan, S., Behboodi-Jooibari, M., Teimouri, R., Asgharzade-Ahmadi, G., Falahati-Naghibi, M., & Sohrabpoor, H. (2013). Optimization of friction stir welding process of AA7075 aluminum alloy to achieve desirable mechanical properties using ANFIS models and simulated annealing algorithm. The International Journal of Advanced Manufacturing Technolology. doi:10.1007/s00170-013-5131-6.

Baseri, H. (2012). Simulated annealing based optimization of dressing conditions for increasing the grinding performance. The International Journal of Advanced Manufacturing Technology, 59, 531–538.

Baseri, H., Rahmani, B., & Bakhshi, M. (2011). Selection of bending parameters for minimal spring-back using an ANFIS model and simulated annealing algorithm. Journal of Manufacturing Science and Engineering ASME Transactions. doi:10.1115/1.4004139.

Chen, S. M., Chang, Y. C., & Pan, J. S. (2013b). Fuzzy rules interpolation for sparse fuzzy rule-based systems based on interval type-2 Gaussian fuzzy sets and genetic algorithms. IEEE Transactions on Fuzzy Systems, 21(3), 412–425.

Chen, S. M., Manalu, G. M. T., Pan, S. J., & Liu, H. C. (2013a). Fuzzy forecasting based on two-factors second-order fuzzy-trend logical relationship groups and particle swarm optimization techniques. IEEE Transactions on Cybernetics, 43(3), 1102–1117.

Dvivedi, A., & Kumar, P. (2007). Surface quality evaluation in ultrasonic drilling through the Taguchi technique. International Journal of Advanced Manufacturing Technology, 34, 131–140.

Katherasan, D., Elias, J. V., Sathiya, P., & Noorul Haq, A. (2012). Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. Journal of Intelligent Manufacturing. doi:10.1007/s10845-012-0675-0.

Kaveh, A., & Talatahari, S. (2010a). Optimum design of skeletal structures using imperialist competitive algorithm. Computers and Structures, 88, 1220–1229.

Kaveh, A., & Talatahari, S. (2010b). Imperialist competitive algorithm for engineering design problems. Asian Journal of Civil Engineering, 11(6), 675–697.

Kumar, J., & Khamba, J. S. (2010). Modeling the material removal rate in ultrasonic machining of titanium using dimensional analysis. International Journal of Advanced Manufacturing Technology, 48, 103–119.

Kumar, J., Khamba, J. S., & Mohapatra, S. K. (2008). An investigation into the machining characteristics of titanium using ultrasonic machining. International Journal of Machining and Machinability of Materials, 3, 143–161.

Kumar, J., Khamba, J. S., & Mohapatra, S. K. (2009). Investigating and modeling tool-wear rate in the ultrasonic machining of titanium. International Journal of Advanced Manufacturing Technology, 41, 1107–1117.

Singh, R., & Khamba, J. S. (2007). Taguchi technique for modeling material removal rate in ultrasonic machining of titanium. Materials Science and Engineering: A, 460–461, 365–369.

Teimouri, R., & Baseri, H. (2012a). Forward and backward predictions of the friction stir weldingparameters using fuzzy-artificial bee colony-imperialist competitive algorithm systems. Journal of Intelligent Manufacturing. doi:10.1007/s10845-013-0784-4.

Teimouri, R., & Baseri, H. (2012b). Artificial evolutionary approaches to produce smoother surface in magnetic abrasive finishing of hardened AISI 52100 steel. Journal of Mechanical Science and Technology, 27, 533–539.

Teimouri, R., & Baseri, H. (2012c). Improvement of dry EDM process characteristics using artificial soft computing methodologies. Production Engineering Research and Development. doi:10.1007/s11740-012-0398-2.

Teimouri, R., Baseri, H., Rahmani, B., & Bakhshi-Jooybari, M. (2012). Modeling and optimization of spring-back in bending process using multiple regression analysis and neural computation. International Journal of Material Forming. doi:10.1007/s12289-012-1117-4.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teimouri, R., Baseri, H. & Moharami, R. Multi-responses optimization of ultrasonic machining process. J Intell Manuf 26, 745–753 (2015). https://doi.org/10.1007/s10845-013-0831-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-013-0831-1