Abstract

To improve capital effectiveness in light of demand fluctuation, it is increasingly important for high-tech companies to develop effective solutions for managing multiple resources involved in the production. To model and solve the simultaneous multiple resources scheduling problem in general, this study aims to develop a genetic algorithm (bvGA) incorporating with a novel bi-vector encoding method representing the chromosomes of operation sequence and seizing rules for resource assignment in tandem. The proposed model captured the crucial characteristics that the machines were dynamic configuration among multiple resources with limited availability and sequence-dependent setup times of machine configurations between operations would eventually affect performance of a scheduling plan. With the flexibility and computational intelligence that GA empowers, schedule planners can make advanced decisions on integrated machine configuration and job scheduling. According to a number of experiments with simulated data on the basis of a real semiconductor final testing facility, the proposed bvGA has shown practical viability in terms of solution quality as well as computation time.

Similar content being viewed by others

References

Allahverdi A., Ng C. T., Cheng T. C. E., Kovalyov M.Y. (2008) A survey of scheduling problems with setup times or costs. European Journal of Operational Research 187(3): 985–1032

Baez Senties O., Azzaro-Pantel Pibouleau C.L., Domenech S. (2010) Multiobjective scheduling for semiconductor manufacturing plants. Computers and Chemical Engineering 34(4): 555–566

Bang J.-Y., Kim Y.-D. (2011) Scheduling algorithms for a semiconductor probing facility. Computers & Operations Research 38(3): 666–673

Barahona F., Bermon S., Gunluk O., Hood S. (2005) Robust capacity planning in semiconductor manufacturing. Naval Research Logistics 52(5): 459–468

Chen T.R., Chang T.S., Chen C.W., Kao J. (1995) Scheduling for IC sort and test with preemptiveness via Lagrangian relaxation. IEEE Transactions on Systems, Man and Cybernetics 25(8): 1249–1256

Chen W., Chien C.-F. (2011) Measuring relative performance of wafer fabrication operations: A case study. Journal of Intelligent Manufacturing 22: 447–457

Cheng R., Gen M., Tsujimura Y. (1996) A tutorial survey of job-shop scheduling problems using genetic algorithms–I. representation. Computers & Industrial Engineering 30(4): 983–997

Cheng R., Gen M., Tsujimura Y. (1999) A tutorial survey of job-shop scheduling problems using genetic algorithms, part II: hybrid genetic search strategies. Computers & Industrial Engineering 36(2): 343–364

Chiang T.-C., Shen Y.-S., Fu L.-C. (2008) A new paradigm for rule-based scheduling in the wafer probe centre. International Journal of Production Research 46(15): 4111–4133

Chien C.-F., Chen C.-H. (2007) Using genetic algorithms (GA) and a coloured timed Petri net (CTPN) for modelling the optimization-based schedule generator of a generic production scheduling system. International Journal of Production Research 45(8): 1763–1789

Chien C.-F., Hu C. (2011) Total Resource Management Framework: An Empirical Study of Semiconductor Fab. Journal of Quality 18(5): 1–26

Chien C.-F., Lin Y.-J., Cheng J.-N. (2008) Construct fuzzy decision tree for mining interrelated semiconductor manufacturing data for yield enhancement. Journal of Quality 15(3): 193–210

Chien C.-F., Wu J.-Z. (2003) Analyzing repair decisions in the site imbalance problem of semiconductor test machines. IEEE Transactions on Semiconductor Manufacturing 16(4): 704–711

Chien C.-F., Chang K.-H., Chen C.-P. (2003) Design of a sampling strategy for measuring and compensating for overlay errors in semiconductor manufacturing. International Journal of Production Research 41(11): 2547–2561

Chien C.-F., Wang W.-C., Cheng J.-C. (2007) Data mining for yield enhancement in semiconductor manufacturing and an empirical study. Expert Systems with Applications 33(1): 192–198

Chien C.-F., Chen Y., Peng J. (2010) Manufacturing intelligence for semiconductor demand forecast based on technology diffusion and product life cycle. International Journal of Production Economics 128(2): 496–509

Deng Y. M., Bard J. F., Chacon G. R., Stuber J. (2010) Scheduling back-end operations in semiconductor manufacturing. IEEE Transactions on Semiconductor Manufacturing 23(2): 210– 220

Ellis K.P., Lu Y., Bish E.K. (2004) Scheduling of wafer test processes in semiconductor manufacturing. International Journal of Production Research 42(2): 215–242

Eppen G., Martin R., Schrage L. (1989) A scenario approach to capacity planning. Operations Research 37(4): 517–527

Fattahi P., Saidi Mehrabad M., Jolai F. (2007) Mathematical modeling and heuristic approaches to flexible job shop scheduling problems. Journal of Intelligent Manufacturing 18(3): 331–342

Freed T., Leachman R. (1999) Scheduling semiconductor device test operations on multihead testers. IEEE Transactions on Semiconductor Manufacturing 12(4): 523–530

Freed T., Doerr K.H., Chang T. (2007) In-house development of scheduling decision support systems: case study for scheduling semiconductor device test operations. International Journal of Production Research 45(21): 5075–5093

Gen M., Cheng R. (1997) Genetic algorithms and engineering design. Wiley-Interscience, New York

Gen M., Cheng R. (2000) Genetic algorithms and engineering optimization. Wiley-interscience, New York

Gen M., Cheng R., Lin L. (2008) Network models and optimization: Multiobjective genetic algorithm approach. Springer, London

Gholami M., Zandieh M. (2009) Integrating simulation and genetic algorithm to schedule a dynamic flexible job shop. Journal of Intelligent Manufacturing 20(4): 481–498

Kim Y., Kim J., Shin K. (2007) An asymmetric multileveled symbiotic evolutionary algorithm for integrated FMS scheduling. Journal of Intelligent Manufacturing 18(6): 631–645

Lee Y.-H., Lee B.-K., Jeong B. (2000) Multi-objective production scheduling of probe process in semiconductor manufacturing. Production Planning & Control 11(7): 660–669

Lin S.-W., Lee Z.-J., Ying K.-C., Lin R.-H. (2010) Meta-heuristic algorithms for wafer sorting scheduling problems. Journal of the Operational Research Society 62(1): 165–174

Lin J.T., Wang F.K., Lee W.T. (2004) Capacity-constrained scheduling for a logic IC final test facility. International Journal of Production Research 42(1): 79–99

LINGO (2002) LINGO 8.0. Chicago: LINDO Systems Inc.

Pearn W.-L., Chung S.-H., Chen A.-Y., Yang M.-H. (2004) A case study on the multistage IC final testing scheduling problem with reentry. International Journal of Production Economics 88(3): 257–267

Qiu R. G., Joshi S., McDonnell P. (2004) An approach to regulating machine sharing in reconfigurable back-end semiconductor manufacturing. Journal of Intelligent Manufacturing 15(5): 579–591

Song Y., Zhang M. T., Yi J., Zhang L., Zheng L. (2007) Bottleneck station scheduling in semiconductor assembly and test manufacturing using ant colony optimization. IEEE Transactions on Automation Science and Engineering 4(4): 569–578

Swaminathan J. (2000) Tool capacity planning for semiconductor fabrication facilities under demand uncertainty. European Journal of Operational Research 120(3): 545–558

Uzsoy R., Martin-Vega L., Lee C., Leonard P. (1991) Production scheduling algorithms for a semiconductor test facility. IEEE Transactions on Semiconductor Manufacturing 4(4): 270–280

Wang K.-J., Hou T.-C. (2003) Modeling and resolving the joint problem of capacity expansion and allocation with multiple resources and limited budget in semiconductor testing industry. International Journal of Production Research 41(14): 3217–3235

Wang K.-J., Lin Y.-S., Chien C.-F., Chen J.-C. (2009) A fuzzy-knowledge resource-allocation model of the semiconductor final test industry. Robotics and Computer-Integrated Manufacturing 25(1): 32–41

Wang K.-J., Wang S.-M., Chen J.-C. (2008) A resource portfolio planning model using sampling-based stochastic programming and genetic algorithm. European Journal of Operational Research 184(1): 327–340

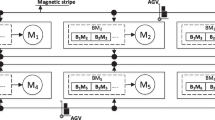

Wu J.-Z., Chien C.-F. (2008a) Modeling semiconductor testing job scheduling and dynamic testing machine configuration. Expert Systems with Applications 35(1–2): 485–496

Wu J.-Z., Chien C.-F. (2008b) Modeling strategic semiconductor assembly outsourcing decisions based on empirical settings. OR Spectrum 30(3): 401–430

Yang X. F., Gen M. (1994) Evolution program for bicriteria transportation problem. Computers & Industrial Engineering 27(1–4): 481–484

Yazdani Sabouni M. T. Y., Jolai F., Mansouri A. (2010) Heuristics for minimizing total completion time and maximum lateness on identical parallel machines with setup times. Journal of Intelligent Manufacturing 21(4): 439–449

Zandieh M., Mozaffari E., Gholami M. (2010) A robust genetic algorithm for scheduling realistic hybrid flexible flow line problems. Journal of Intelligent Manufacturing 21(6): 731–743

Zhang M., Niu S., Deng S., Zhang Z., Li Q., Zheng L. (2007) Hierarchical capacity planning with reconfigurable kits in global semiconductor assembly and test manufacturing. IEEE Transactions on Automation Science and Engineering 4(4): 543–552

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, JZ., Hao, XC., Chien, CF. et al. A novel bi-vector encoding genetic algorithm for the simultaneous multiple resources scheduling problem. J Intell Manuf 23, 2255–2270 (2012). https://doi.org/10.1007/s10845-011-0570-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-011-0570-0