Abstract

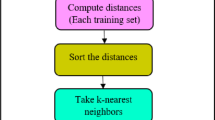

Accurate estimation of the bearing capacity of piles requires complex modelling techniques which are not justified by timeframe, budget, or scope of the projects. In this study, six advanced machine learning algorithms including decision tree, k-nearest neighbour, multilayer perceptron artificial neural network, random forest, support vector regressor and extremely gradient boosting are employed to model the bearing capacity of piles in cohesionless soil, and the particle swarm optimisation algorithm is used to optimate the hyper-parameters of machine learning algorithms. A dataset comprising of 59 cases is employed and the R-squared value, root mean square error and variance accounted for are used as performance metrics to compare the performance of optimised machine learning methods. The comparison reveals that the optimised machine learning methods have great potential to estimate bearing capacity of piles and the particle swarm optimisation algorithm is efficient in the hyper-parameter tuning. The results show that R-squared values of six optimised machine learning approaches on the testing set vary from 0.731 to 0.9615. Also, the optimised extremely gradient boosting (R-squared value = 0.9615) shows the best performance compared with other algorithms. Furthermore, the relative importance of influential variable is investigated, which shows that effective stress is the most influential variable for bearing capacity of piles with an importance score of 30.9%. In addition, the results by the optimised machine learning method are compared to the β-method which is a popular empirical method. It is revealed the prominent performance of optimised machine learning approaches.

Similar content being viewed by others

References

Abu-Farsakh MY, Titi HH (2004) Assessment of direct cone penetration test methods for predicting the ultimate capacity of friction driven piles. J Geotech Geoenviron Eng 130(9):935–944

Alkroosh I, Nikraz H (2011) Correlation of pile axial capacity and CPT data using gene expression programming. Geotech Geol Eng 29(5):725–748

Alkroosh I, Nikraz H (2014) Predicting pile dynamic capacity via application of an evolutionary algorithm. Soils Found 54(2):233–242

Altman NS (1992) An introduction to kernel and nearest-neighbor nonparametric regression. Am Stat 46(3):175–185

Armaghani DJ, Raja RSNSB, Faizi K, Rashid ASA (2017) Developing a hybrid PSO–ANN model for estimating the ultimate bearing capacity of rock-socketed piles. Neural Comput Appl 28(2):391–405

Baghban A, Kardani MN, Mohammadi AH (2018) Improved estimation of Cetane number of fatty acid methyl esters (FAMEs) based biodiesels using TLBO-NN and PSO-NN models. Fuel 232:620–631

Cameron AC, Windmeijer FA (1997) An R-squared measure of goodness of fit for some common nonlinear regression models. J Econom 77(2):329–342

Cao M, Zhou A (2019) Analytical solutions to interaction factors of two unequal length piles under horizontal loads. Int J Geomech 19(4):06019003

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE) arguments against avoiding RMSE in the literature. Geosci Model Dev 7(3):1247–1250

Chen T, Guestrin C (2016) Xgboost: a scalable tree boosting system. In: Proceedings of the 22nd ACM SIGKDD international conference on knowledge discovery and data mining. ACM. pp 785–794

Chen T, He T, Benesty M, Khotilovich V, Tang Y (2015) Xgboost: extreme gradient boosting. R package version 0.4-2: 1–4

Chen X, Huang L, Xie D, Zhao Q (2018) EGBMMDA: extreme gradient boosting machine for MiRNA-disease association prediction. Cell Death Dis 9(1):3

Chow Y, Karunaratne G, Wong K, Lee S (1988) Prediction of load-carrying capacity of driven piles. Can Geotech J 25(1):13–23

Coyle HM, Castello RR (1981) New design correlations for piles in sand. J Geotech Geoenviron Eng 107:965–986

Das SK, Basudhar PK (2006) Undrained lateral load capacity of piles in clay using artificial neural network. Comput Geotech 33(8):454–459

Das SK, Sivakugan N (2010) Discussion of “Intelligent computing for modeling axial capacity of pile foundations”. Can Geotech J 47(8):928–930

Eberhart R, Kennedy J (1995) Particle swarm optimization. In: Proceedings of the IEEE international conference on neural networks. 1995. Citeseer. pp 1942–1948

Eberhart R, Simpson P, Dobbins R (1996) Computational intelligence PC tools. Academic Press Professional Inc, New York

Fellenius BH (1991) Pile foundations. In: Foundation engineering handbook. Springer, Boston, pp 511–536

Gao Y, Sun DA, Zhou AN (2015) Hydromechanical behaviour of unsaturated soil with different specimen preparations. Can Geotech J 53(6):909–917

Garcia S, Derrac J, Cano JR, Herrera F (2011) Prototype selection for nearest neighbor classification: taxonomy and empirical study. IEEE Trans Pattern Anal Mach Intell 3:417–435

Guo X, Yang J, Wu C, Wang C, Liang Y (2008) A novel LS-SVMs hyper-parameter selection based on particle swarm optimization. Neurocomputing 71(16–18):3211–3215

Guyon I, Gunn S, Nikravesh M, Zadeh LA (2008) Feature extraction: foundations and applications. Springer, Berlin

Ho TK (1995) Random decision forests. In: Proceedings of 3rd international conference on document analysis and recognition, IEEE. pp 278–282

Jin X, Wang T, Cheng W-C, Luo Y, Zhou A (2018) A simple method for settlement evaluation of loess-pile foundation. Can Geotech J. https://doi.org/10.1139/cgj-2017-0690

Kennedy J (2010) Particle swarm optimization. Encycl Mach Learn. Springer, pp 760–766. https://doi.org/10.1007/978-0-387-30164-8_630

Kiefa MA (1998) General regression neural networks for driven piles in cohesionless soils. J Geotech Geoenviron Eng 124(12):1177–1185

Ma C, Lu DC, Du XL, Zhou AN (2017) Developing a 3D elastoplastic constitutive model for soils: a new approach based on characteristic stress. Comput Geotech 86:129–140

Mantovani RG, Rossi AL, Vanschoren J, Bischl B, De Carvalho AC (2015) Effectiveness of random search in SVM hyper-parameter tuning. In: 2015 international joint conference on neural networks (IJCNN), IEEE. pp 1–8

Mayerhof G (1976) Bearing capacity and settlemtn of pile foundations. J Geotech Geoenviron Eng 102:195–228

Moayedi H, Armaghani DJ (2018) Optimizing an ANN model with ICA for estimating bearing capacity of driven pile in cohesionless soil. Eng Comput 34(2):347–356

Moayedi H, Hayati S (2018) Modelling and optimization of ultimate bearing capacity of strip footing near a slope by soft computing methods. Appl Soft Comput 66:208–219

Moayedi H, Moatamediyan A, Nguyen H, Bui X-N, Bui DT, Rashid ASA (2019) Prediction of ultimate bearing capacity through various novel evolutionary and neural network models. Eng Comput. https://doi.org/10.1007/s00366-019-00723-2

Mohanty R, Suman S, Das SK (2018) Prediction of vertical pile capacity of driven pile in cohesionless soil using artificial intelligence techniques. Int J Geotech Eng 12(2):209–216

Momeni E, Nazir R, Armaghani DJ, Maizir H (2014) Prediction of pile bearing capacity using a hybrid genetic algorithm-based ANN. Measurement 57:122–131

Muduli PK, Das SK, Das MR (2013) Prediction of lateral load capacity of piles using extreme learning machine. Int J Geotech Eng 7(4):388–394

Pal M, Deswal S (2010) Modelling pile capacity using Gaussian process regression. Comput Geotech 37(7–8):942–947

Poulos HG, Davis EH (1980) Pile foundation analysis and design. Wiely, New york

Randolph MF (2003) Science and empiricism in pile foundation design. Géotechnique 53(10):847–876

Randolph MF, Murphy B (1985) Shaft capacity of driven piles in clay. In: Offshore technology conference

Rodriguez JD, Perez A, Lozano JA (2010) Sensitivity analysis of k-fold cross validation in prediction error estimation. IEEE Trans Pattern Anal Mach Intell 32(3):569–575

Rokach L, Maimon OZ (2008) Data mining with decision trees: theory and applications. World scientific, Singapore

Samui P (2011) Prediction of pile bearing capacity using support vector machine. Int J Geotech Eng 5(1):95–102

Samui P (2012a) Application of relevance vector machine for prediction of ultimate capacity of driven piles in cohesionless soils. Geotech Geol Eng 30(5):1261–1270

Samui P (2012b) Determination of ultimate capacity of driven piles in cohesionless soil: a multivariate adaptive regression spline approach. Int J Numer Anal Methods Geomech 36(11):1434–1439

Sarir P, Shen SL, Wang ZF, Chen J, Horpibulsuk S, Pham BT (2019) Optimum model for bearing capacity of concrete-steel columns with AI technology via incorporating the algorithms of IWO and ABC. Eng Comput. https://doi.org/10.1007/s00366-019-00855-5

Suman S, Das SK, Mohanty R (2016) Prediction of friction capacity of driven piles in clay using artificial intelligence techniques. Int J Geotech Eng 10(5):469–475

Svinkin MR (2002) Engineering judgement in determination of pile capacity by dynamic methods. In: Deep foundations 2002: an international perspective on theory, design, construction, and performance, pp 898–914

Teh C, Wong K, Goh A, Jaritngam S (1997) Prediction of pile capacity using neural networks. J Comput Civil Eng 11(2):129–138

Wang L (2005) Support vector machines: theory and applications. Springer, Berlin

Wu HN, Shen SL, Yang J, Zhou AN (2018) Soil-tunnel interaction modelling for shield tunnels considering shearing dislocation in longitudinal joints. Tunn Undergr Sp Technol 78:168–177

Yao YP, Hu J, Zhou AN, Luo T, Wang N (2015) Unified strength criterion for soils, gravels, rocks, and concretes. Acta Geotech 10(6):749–759

Zhang W, Goh AT (2016) Multivariate adaptive regression splines and neural network models for prediction of pile drivability. Geosci Front 7(1):45–52

Zhang N, Shen SL, Zhou AN, Arulrajah A (2018) Tunneling induced geohazards in mylonitic rock faults with rich groundwater: a case study in Guangzhou. Tunn Undergr Sp Technol 74:262–272

Zhang N, Shen SL, Zhou AN, Xu YS (2019) Investigation on performance of neural networks using quadratic relative error cost function. IEEE Access 7:106642–106652. https://doi.org/10.1109/ACCESS.2019.2930520

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Dataset of the Multinational Pile Cases

See Table 5.

Appendix 2: Calculating the Unit Shaft Resistance

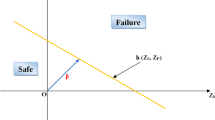

In an effective stress analysis, the unit shaft resistance is calculated from the following expression:

where \(\beta = K^{\prime}{ \tan }\left( \delta \right)\), \(\sigma^{\prime}_{\text{v}}\) is the effective vertical stress and C is the pile circumference. Usually \(c_{a}\) is set to zero for driven piles but may be non-zero for cast-in-place piles. Fellenius (1991) tells us that typical values for \(\beta\) depend on soil gradation, mineral composition, density and soil strength within a fairly narrow range. Some empirical ranges for \(\beta\) coefficients in different soil types are,

Meyerhof (1976) has proposed values of \(K^{\prime}{ \tan }\left( \delta \right)\) for driven piles. Note that the shaft resistance values reflect the likely changes of stress state in the soil due to the method of installation. In using Table 6, the undisturbed value is used in all cases.

The unit base resistance is calculated from:

where \(N_{t}\) = base bearing capacity coefficient, \(A_{p}\) = cross-sectional area and \(\sigma^{\prime}_{\text{v}}\) = effective stress.

Recommended ranges of β and \(N_{t}\) coefficients as a function of soil type and φs angle from Fellenius (1991) are presented in Table 6. Fellenius notes that factors affecting the β and \(N_{t}\), coefficients consist of the soil composition including the grain size distribution angularity and mineralogical origin of the soil grains, the original soil density and density due to the pile installation technique, the soil strength, as well as other factors. Even so, β coefficients are generally within the ranges provided and seldom exceed 1.0.

For sedimentary cohesionless deposits, Fellenius states \(N_{t}\), ranges from about 30 to a high of 120. In very dense non-sedimentary deposits such as glacial tills,\(N_{t}\) can be much higher, but can also approach the lower bound value of 30. In clays, Fellenius notes that the toe resistance calculated using a \(N_{t}\) of 3 that is similar to the toe resistance calculated from a traditional analysis using undrained shear strength. Therefore, the use of a relatively low \(N_{t}\), coefficient in clays is recommended unless local correlations suggest higher values are appropriate.

Graphs of the ranges in β and \(N_{t}\) coefficients versus the range in φs angle as suggested by Fellenius. These graphs may be helpful in the selection of β or \(N_{t}\). The inexperienced user should select conservative β and \(N_{t}\) coefficients. As with any design method, the user should also confirm the appropriateness of a selected β or \(N_{t}\), coefficient in a given soil condition with local correlations between static capacity calculations and static load tests results.

It should be noted that the effective stress method places no limiting values on either the shaft or base resistance.

Step 1 Delineate the soil profile into layers and determine φs angle for each layer.

- a.

Construct \(\sigma^{\prime}_{\text{v}}\) diagram along the depth of the pile.

- b.

Divide soil profile throughout the pile penetration depth into layers and determine the effective stress,\(\sigma^{\prime}_{\text{v}}\), at the midpoint of each layer.

- c.

Determine the φs angle for each soil layer from laboratory or in-situ test data.

- d.

In the absence of laboratory or in-situ data for cohesionless layers, determine the average corrected Ncor value for each layer and estimate φs angle from Schmertmanns (1975) SPT correlation for soils.

Step 2 Select the β coefficient for each soil layer.

- a.

Utilise local experience to select β coefficient for each layer.

- b.

In the absence of local experience, use Meyerhof’s Pile Factors to estimate β coefficient from φs angle for each layer. NB \(\beta = K^{\prime}{ \tan }\left( \delta \right)\)

Step 3 For each soil layer calculate the shaft resistance \(Q_{s}\) (kPa) from Eq. (1). The total shaft resistance is simply the sum of the shaft resistance from each soil layer.

Step 4 Calculate the ultimate toe resistance, \(Q_{m}\) (kPa).

- a.

Utilise local experience to select \(N_{t}\) coefficient.

- b.

In the absence of local experience, estimate \(N_{t}\), from Table 6 based on φs angle.

- c.

Calculate the effective stress at the pile base, \(\sigma^{\prime}_{\text{v}}\).

Step 5 Calculate the ultimate pile capacity, \(Q_{m} = Q_{s} \left( {KN} \right) + Q_{p}\).

Rights and permissions

About this article

Cite this article

Kardani, N., Zhou, A., Nazem, M. et al. Estimation of Bearing Capacity of Piles in Cohesionless Soil Using Optimised Machine Learning Approaches. Geotech Geol Eng 38, 2271–2291 (2020). https://doi.org/10.1007/s10706-019-01085-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-019-01085-8