Abstract

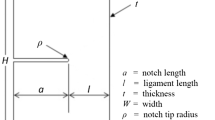

The current solutions in ASTM E1820 and E1921 for the calculation of the J-integral are not necessary directly applicable for strength mismatched welds. The problem is connected to the \(\eta \)-factor relating the experimentally measured work to the J-integral. Previous, investigations on \(\eta \)-factors for welds have focused mainly on cracks at the center of the weld. However, characterisation of the \(\eta \)-factor at other locations is also important since the crack can form anywhere in the weld. In this study, the \(\eta \)-factors for SE(B) specimens were investigated, with focus on the effect of the crack location relative to the fusion boundary between a hard base metal and a soft weld metal of a dissimilar metal weld. The results show a dependence between the \(\eta ^{\textit{CMOD}}\)-factor, the distance of the crack to the fusion boundary, the size of the remaining ligament, and the size of the plastic deformation zone. This dependence cannot be generalised based on this study alone, but the results give insight for developing an analytical \(\eta ^{\textit{CMOD}}\)-equation for strength mismatched specimens.

Similar content being viewed by others

References

Ait-Bachir M, Beleznai R, Blasset S et al (2015) Final report of the MULTIMETAL project. MULTIMETAL: structural performance of multimetal components. European Commission: Seventh Framework Programme, 80. https://cordis.europa.eu/result/rcn/169011_en.html

Anderson TL (2005) Fracture mechanics: fundamentals and applications, 3rd edn. Taylor & Francis Group, LLC, London

ASTM E1820-15 (2015) Standard test method for measurement of fracture toughness. ASTM International, West Conshohocken

ASTM E1921-15 (2015) Standard test method for determination of reference temperature, T0, for ferritic steels in the transition range. ASTM International, West Conshohocken

Bourgeois M, Perez G, Chapuliot S (2015) Fracture properties in dissimilar metal weld junctions: experimental methodology of characterization. In: ASME 2015 pressure vessels and piping conference, pp 1–10

Donato GHB, Ruggieri C (2006) Estimation procedures for J and CTOD fracture parameters using three-point bend specimens. In: 6th International pipeline conference, Calgary, pp 1–9

Donato GHB, Magnabosco R, Ruggieri C (2009) Effects of weld strength mismatch on J and CTOD estimation procedure for SE(B) specimens. Int J Fract 159:1–20. https://doi.org/10.1007/s10704-009-9377-9

Hänninen H, Brederholm A, Sarikka T et al (2014) Structural Integrity of Ni-base Alloy Welds. VTT publications 257. http://www.vtt.fi/inf/pdf/technology/2014/T175.pdf

Koçak M (2010) Structural integrity of welded structures?: process–property–performance (3P) relationship. In: 63rd Annual assembly and international conference of the International Institute of Welding, pp 3–19

Koo J-M, Huh Y, Seok C-S (2012) Plastic \(\eta \) factor considering strength mismatch and crack location in narrow gap weldments. Nucl Eng Des 247:34–41. https://doi.org/10.1016/j.nucengdes.2012.02.016

Lindqvist S (2014) Fracture mechanical characterisation of multimetal welds. Aalto university, Espoo

Lindqvist S (2016) Tearing resistance of heterogeneous interface region of a dissimilar metal weld characterised with sub-sized single edge bend specimens. Procedia Struct Integr 2:1031–1038. https://doi.org/10.1016/j.prostr.2016.06.132

Paredes M, Ruggieri C (2012) Further results in J and CTOD estimation procedures for SE(T) fracture specimens. Part II. Weld centerline cracks. Eng Fract Mech 89:24–39. https://doi.org/10.1016/j.engfracmech.2012.03.010

Ruggieri C (2012) Further results in J and CTOD estimation procedures for SE(T) fracture specimens. Part I. Homogeneous materials. Eng Fract Mech 79:245–265. https://doi.org/10.1016/j.engfracmech.2011.11.003

Savioli RG, Ruggieri C (2013) J and CTOD estimation formulas for C(T) fracture specimens including effects of weld strength overmatch. Int J Fract 179:109–127. https://doi.org/10.1007/s10704-012-9781-4

Simonovski I, Oliver M, Bourgeois M et al (2015) J-integral fracture toughness assessment of specimens containing dissimilar metal welds. In: 23nd Conference on structural mechanics in reactor technology (SMiRT), Manchester

Wallin K (2011) Fracture toughness of engineering materials—estimation and application. EMAS Publishing, Warrington

Wang HT, Wang GZ, Xuan FZ, Tu ST (2013) An experimental investigation of local fracture resistance and crack growth paths in a dissimilar metal welded joint. Mater Des 44:179–189. https://doi.org/10.1016/j.matdes.2012.07.067

Xuan FZ, Tu ST, Wang Z (2005) A modification of ASTM E 1457 C* estimation equation for compact tension specimen with a mismatched cross-weld. Eng Fract Mech 72:2602–2614. https://doi.org/10.1016/j.engfracmech.2005.05.002

Zhou H, Biglari F, Davies CM et al (2014) Evaluation of fracture mechanics parameters for a range of weldment geometries with different mismatch ratios. Eng Fract Mech 124–125:30–51. https://doi.org/10.1016/j.engfracmech.2014.03.006

Zhu X (2009) J-integral resistance curve testing and evaluation. J Zhejiang Univ Sci A 10:1541–1560. https://doi.org/10.1631/jzus.A0930004

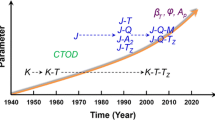

Zhu XK, Joyce JA (2012) Review of fracture toughness (G, K, J, CTOD, CTOA) testing and standardization. Eng Fract Mech 85:1–46

Zhu X, Leis BN, Joyce JA (2008) Experimental estimation of JR curves from load-CMOD record for SE (B) specimens. J ASTM Int 5:15. https://doi.org/10.1520/JAI101532

Acknowledgements

The writing of this paper was funded by Project LOST (Long term operational aspects of structural integrity) that is part of SAFIR2018 (The Finnish Research Programme on Nuclear Power Plant Safety 2015–2018). The experimental results on which the numerical work is based on were obtained in a European collaboration Project called MULTIMETAL that was funded by the European Commission (EC) within its 7th Framework Program and completed in January 2015.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lindqvist, S., Kuutti, J. Dependence between \(\varvec{\upeta }\)-factor and crack location relative to a fusion boundary between hard and soft materials in a SE(B) specimen. Int J Fract 211, 281–293 (2018). https://doi.org/10.1007/s10704-018-0288-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-018-0288-5