Abstract

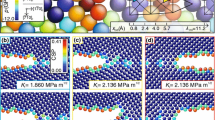

Fracture modeling at the atomic scale is currently an intense area of research because the crack propagation process depends strongly on the description of interatomic interactions. Here we present first the mode-I plane strain quasi-static fracture toughness of single crystal silicon, along four orientations, as obtained using molecular statics simulations with nine empirical potentials. The “best” potential is determined by comparing the fracture toughness and trapping range of the simulations with available experimental data and with results calculated using first-principles molecular dynamics. The choice is buttressed by its ability to predict the effective toughness and propagation direction of a crack subjected to mode-II loading. The best performing potential is then used to investigate the fracture toughness and the role of bond trapping for a crack along the boundary of two silicon crystals belonging to two different tilt families.

Similar content being viewed by others

References

Bailey NP, Sethna JP (2003) Macroscopic measure of the cohesive length scale: fracture of notched single-crystal silicon. Phys Rev B 68(205):204

Balamane H, Halicioglu T, Tiller WA (1992) Comparative study of silicon empirical interatomic potentials. Phys Rev B 46:2250–2279

Baskes MI (1992) Modified embedded-atom potentials for cubic materials and impurities. Phys Rev B 46:2727–2742

Bassani J, Qu J (1989) Finite crack on bimaterial and bicrystal interfaces. J Mech Phys Solids 37(4):435–453

Bernstein N, Hess DW (2003) Lattice trapping barriers to brittle fracture. Phys Rev Lett 91(025):501

Bitzek E, Koskinen P, Gähler F, Moseler M, Gumbsch P (2006) Structural relaxation made simple. Phys Rev Lett 97(170):201

Bitzek E, Kermode JR, Gumbsch P (2015) Atomistic aspects of fracture. Int J Fract 191(1):13–30

Buehler MJ, van Duin ACT, Goddard WA (2006) Multiparadigm modeling of dynamical crack propagation in silicon using a reactive force field. Phys Rev Lett 96(095):505

DiVincenzo DP, Alerhand OL, Schlüter M, Wilkins JW (1986) Electronic and structural properties of a twin boundary in Si. Phys Rev Lett 56:1925–1928

Du YA, Lenosky TJ, Hennig RG, Goedecker S, Wilkins JW (2011) Energy landscape of silicon tetra-interstitials using an optimized classical potential. Phys Status Solidi B 248(9):2050–2055

Erdogan F, Sih GC (1963) On the crack extension in plates under plane loading and transverse shear. J Basic Eng 85(4):519–525

Fitzgerald AM, Iyer RS, Dauskardt R, Kenny TW (2002) Subcritical crack growth in single-crystal silicon using micromachined specimens. J Mater Res 17:683–692

Gao H, Abbudi M, Barnett D (1992) Interfacial crack-tip field in anisotropic elastic solids. J Mech Phys Solids 40(2):393–416

George A, Michot G (1993) Dislocation loops at crack tips: nucleation and growth—an experimental study in silicon. Mater Sci Eng A 164(1–2):118–134

Gilman JJ (1960) Direct measurements of the surface energies of crystals. J Appl Phys 31(12):2208–2218

Gumbsch P, Cannon R (2000) Atomistic aspects of brittle fracture. MRS Bull 25:15–20

Hall JJ (1967) Electronic effects in the elastic constants of \(n\)-type silicon. Phys Rev 161:756–761

Holland D, Marder M (1998) Erratum: ideal brittle fracture of silicon studied with molecular dynamics. Phys Rev Lett 81:4029–4029 [phys. rev. lett. 80, 746 (1998)]

Holland D, Marder M (1998b) Ideal brittle fracture of silicon studied with molecular dynamics. Phys Rev Lett 80:746–749

Jaccodine RJ (1963) Surface energy of germanium and silicon. J Electrochem Soc 110(6):524–527

Justo JF, Bazant MZ, Kaxiras E, Bulatov VV, Yip S (1998) Interatomic potential for silicon defects and disordered phases. Phys Rev B 58:2539–2550

Kermode JR, Albaret T, Sherman D, Bernstein N, Gumbsch P, Payne MC, Csanyi G, De Vita A (2008) Low-speed fracture instabilities in a brittle crystal. Nature 455(7217):1224–1227

Kermode JR, Gleizer A, Kovel G, Pastewka L, Csányi G, Sherman D, De Vita A (2015) Low speed crack propagation via kink formation and advance on the silicon (110) cleavage plane. Phys Rev Lett 115(135):501

Kohyama M (1987) Structures and energies of symmetrical \(\langle 001 \rangle \) tilt grain boundaries in silicon. Phys Status Solidi B 141(1):71–83

Kohyama M (2002) Computational studies of grain boundaries in covalent materials. Modell Simul Mater Sci Eng 10(3):R31

Kohyama M, Yamamoto R (1994) Tight-binding study of grain boundaries in si: energies and atomic structures of twist grain boundaries. Phys Rev B 49:17,102–17,117

Kohyama M, Yamamoto R, Doyama M (1986) Structures and energies of symmetrical \(\langle 011 \rangle \) tilt grain boundaries in silicon. Phys Status Solidi B 137(1):11–20

Kumagai T, Izumi S, Hara S, Sakai S (2007) Development of bond-order potentials that can reproduce the elastic constants and melting point of silicon for classical molecular dynamics simulation. Comput Mater Sci 39(2):457–464

Lenosky TJ, Sadigh B, Alonso E, Bulatov VV, de la Rubia TD, Kim J, Voter AF, Kress JD (2000) Highly optimized empirical potential model of silicon. Modell Simul Mater Sci Eng 8(6):825

Möller JJ, Bitzek E (2014a) Comparative study of embedded atom potentials for atomistic simulations of fracture in \(\alpha \)-iron. Modell Simul Mater Sci Eng 22(4):045,002

Möller JJ, Bitzek E (2014b) Fracture toughness and bond trapping of grain boundary cracks. Acta Mater 73:1–11

Nicklas JWC (2013) Methods for accurately modeling complex materials. Ph.D. thesis, Ohio State University

Pastewka L, Klemenz A, Gumbsch P, Moseler M (2013) Screened empirical bond-order potentials for si-c. Phys Rev B 87(205):410

Perez R, Gumbsch P (2000) Directional anisotropy in the cleavage fracture of silicon. Phys Rev Lett 84:5347–5350

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Qu J, Bassani J (1989) Cracks on bimaterial and bicrystal interfaces. J Mech Phys Solids 37(4):417–433

Ratanaphan S, Yoon Y, Rohrer GS (2014) The five parameter grain boundary character distribution of polycrystalline silicon. J Mater Sci 49(14):4938–4945

Roundy D, Cohen ML (2001) Ideal strength of diamond, si, and ge. Phys Rev B 64(212):103

Samuels J, Roberts SG (1989) The brittle-ductile transition in silicon. i. experiments. Proc R Soc Lond Ser A 421(1860):1–23

Sen D, Thaulow C, Schieffer SV, Cohen A, Buehler MJ (2010) Atomistic study of crack-tip cleavage to dislocation emission transition in silicon single crystals. Phys Rev Lett 104:235,502

Sih GC, Paris PC, Irwin GR (1965) On cracks in rectilinearly anisotropic bodies. Int J Fract Mech 1(3):189–203

Sinclair JE, Lawn BR (1972) An atomistic study of cracks in diamond-structure crystals. Proc R Soc London Ser A 329(1576):83–103

Singh G, Kermode JR, Vita A, Zimmerman RW (2014) Validity of linear elasticity in the crack-tip region of ideal brittle solids. Int J Fract 189(1):103–110

Stillinger FH, Weber TA (1985) Computer simulation of local order in condensed phases of silicon. Phys Rev B 31:5262–5271

Stukowski A (2010) Visualization and analysis of atomistic simulation data with ovito—the open visualization tool. Modell Simul Mater Sci Eng 18(1):015,012

Suo Z (1990) Singularities, interfaces and cracks in dissimilar anisotropic media. Proc R Soc Lond Ser A 427(1873):331–358

Tersoff J (1988) Empirical interatomic potential for silicon with improved elastic properties. Phys Rev B 38:9902–9905

Thomson R, Hsieh C, Rana V (1971) Lattice trapping of fracture cracks. J Appl Phys 42:3154

Tsai Y, Mecholsky J (1991) Fractal fracture of single crystal silicon. J Mater Res 6:1248–1263

Windisch D, Becker P (1990) Silicon lattice parameters as an absolute scale of length for high precision measurements of fundamental constants. Phys Status Solidi A 118(2):379–388

Wu KC (1990) Stress intensity factor and energy release rate for interfacial cracks between dissimilar anisotropic materials. J Appl Mech 57(4):882–886

Zhang H, Tersoff J, Xu S, Chen H, Zhang Q, Zhang K, Yang Y, Lee CS, Tu KN, Li J, Lu Y (2016) Approaching the ideal elastic strain limit in silicon nanowires. Sci Adv 2(8):e1501382

Zhu T, Li J, Yip S (2006) Atomistic characterization of three-dimensional lattice trapping barriers to brittle fracture. Proc R Soc Lond Ser A 462(2070):1741–1761

Acknowledgements

The authors gratefully acknowledge the financial support from the U.S. National Science Foundation for this research through Grant NSF/CMMI-1361868.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Elasticity matrices

The elastic stiffness tensor of a (010)[001] oriented Si SC, that has cubic symmetry, can be expressed in matrix form using the Voigt notation as

where \(C_{11}\), \(C_{12}\), and \(C_{44}\) are the only three independent elastic constants, listed in Table 1 for different interatomic potentials. Next, the forth order stiffness tensor for an arbitrary crystal orientation \((\mathbf{n}_2)[\mathbf{n}_3]\), labeled in accordance with the crack system notation and defined by the rotation matrix \({{\varvec{\varOmega }}}\), can be obtained in the following way.

where Einstein summation rule is used. The matrix \({{\varvec{\varOmega }}}\), that rotates the initial (010)[001] crystal system around axis \(\mathbf{m}\) by angle \(\theta _0\) so that it orients the crystal as \((\mathbf{n}_2)[\mathbf{n}_3]\) (i.e. it has \(\mathbf{n}_2\) crystallographic orientation along y axis and \(\mathbf{n}_3\) along z axis), writes as

where \(\delta \) is the Kronecker delta and \(\epsilon \) is the Levi-Civita symbol.

For a SC system we define the stiffness tensor \(\mathbf{C}\) obtained by applying rotational transformation \({{\varvec{\varOmega }}}^{\mathbf{m}}_{\theta _0}\) shown in Eq. (A.3), where axis \(\mathbf{m}\) and angle \(\theta _0\) are dictated by the considered crystal orientation, to the initial \(\mathbf{C}^{(0)}\) given in Eq. (A.1). For the tilt boundaries we also find the stiffnesses \(\mathbf{C}^{(1)}\) and \(\mathbf{C}^{(2)}\) obtained by additional rotation about z axis by angles \(\theta _1\) and \(\theta _2\) of a SC with stiffness \(\mathbf{C}={{\varvec{\varOmega }}}^{\mathbf{m}}_{\theta _0}\mathbf{C}^{(0)}\); this transformation is denoted by \({{\varvec{\varOmega }}}^{z}_{\theta _{\beta }}\) where \(\beta =1\) and 2 correspond to the solutions for \(\theta \in (0,\pi )\) and \(\theta \in (-\pi ,0)\) regions, respectively, see Fig. 1. Equivalently, \(\mathbf{C}^{(\beta )}\) can be computed by applying the total rotation operation being a product of two as \({{\varvec{\varOmega }}}^{(\beta )}={{\varvec{\varOmega }}}^{z}_{\theta _{\beta }}{{\varvec{\varOmega }}}^{\mathbf{m}}_{\theta _0}\) to \(\mathbf{C}^{(0)}\) according to Eq. (A.2). For example, a (110)[001] SC system has \(\mathbf{m}=(0,0,1)^{{\mathsf {T}}}\), \(\theta _0=\pi /4\); \((110)[1\bar{1}0]\) has \(\mathbf{m}=(-0.357,-0.863,0.357)^{\mathsf{T}}\), \(\theta _0=1.718\); \((111)[1\bar{1}0]\) has \(\mathbf{m}=(-0.642,-0.762,0.085)^{\mathsf{T}}\), \(\theta _0=1.578\); \((111)[11\bar{2}]\) has \(\mathbf{m}=(-0.367,-0.887,-0.282)^{\mathsf{T}}\), \(\theta _0=2.909\).

Appendix B: Linear elastic solution for a bimaterial interface crack

This section briefly reviews the linear elastic solution obtained by Qu and Bassani (1989) and Bassani and Qu (1989) and includes the key expression needed to implement the used boundary conditions. In a rectangular coordinate system \(x_i\) (\(i=1,2,3\); \(x_1\), \(x_2\), \(x_3\) correspond x, y, z coordinate system used in the paper), the infinitesimal strain tensor, defined as \(\varepsilon _{ij}=\frac{1}{2}(u_{i,j}+u_{j,i})\), where comma refers to the partial derivative, \(\mathbf{u}\) is the displacement, is related to the Cauchy stress tensor as \(\sigma _{ij}=C_{ijkl}\varepsilon _{kl}\). Then the equilibrium equation writes as

In case of the two-dimensional plain strain problem considered here \(\varepsilon _{i3}=0\), \(u_i=u_i(x_1,x_2)\). It allows to search for a solution in the form of \(u_i=a_i f(z)\), where f is an arbitrary function of complex variable \(z=x_1+px_2\). Substituting it into Eq. (B.1) leads to the following eigenvalue problem

that yield six roots for p and corresponding eigenvectors a. Here are \(\mathbf{Q}\), \(\mathbf{R}\), \(\mathbf{T}\) are the elasticity matrices defined as \(Q_{ik}=C_{i1k1}\), \(R_{ik}=C_{i1k2}\), \(T_{ik}=C_{i2k2}\). Since \(\mathbf{C}\) is positive definite, there are three pairs of complex conjugate roots, so that \({\text {Im}}(p_{\alpha })>0\), \(p_{\alpha +3}=\bar{p}_{\alpha }\) (overbar denotes the complex conjugate) for \(\alpha =1,2,3\). Next, additional matrices are introduced as \(\mathbf{P}={\text {diag}}[p_1,p_2,p_3]=\langle p_{\alpha } \rangle \), \(\mathbf{A}=[\mathbf{a}_1,\mathbf{a}_2,\mathbf{a}_3]\), \(\mathbf{B}=\mathbf{R}^{\mathsf{T}}\mathbf{A}+\mathbf{T}\mathbf{A}\mathbf{P}\).

Moving to the interface crack problem, we first identify the matrices introduced above for a SC of a given orientation with stiffness \(\mathbf{C}\) before tilt is applied, i.e. for perfect structure without the interface. Then, the properties of the system with a tilt boundary are computed as

\(\beta =1\) and 2 correspond to the solutions for materials having different tilt angles, i.e. for \(y>0\) and \(y<0\) regions, respectively. Solving for the asymptotic stress and displacement fields produced at the interface crack tip, Bassani and Qu (1989) introduced matrices \(\mathbf{W}\) and \(\mathbf{D}\) as

which reflect continuity of displacements and tractions across the bimaterial interface. Qu and Bassani (1989) also proved that if \(\mathbf{W}=\mathbf{0}\) the crack tip fields are not oscillatory, i.e. solution for the stress field has the standard inverse square root singularity.

For the particular case of uniform tractions applied along the crack faces, that can be represented by the stress intensity vector \(\mathbf{k} = (K_{\mathrm{II}},K_{\mathrm{I}},K_{\mathrm{III}})^{\mathsf{T}}\), for bimaterial satisfying \(\mathbf{W}=\mathbf{0}\) the linear elastic solution for the stress being function of radial distance r and polar angle \(\theta \) derived by Bassani and Qu (1989) takes the following form

The asymptotic behavior of the displacements can be deduced from the full finite crack solution given in Eqs. (3.14a,b) in Bassani and Qu (1989) and it writes as

The crack opening displacement can be calculated as

Besides, according to Wu (1990), the energy release rate becomes

Although this approach may seem complicated and unnecessary for the problems considered here, since the solution for a uniformly loaded interface crack of \(\mathbf{W}=\mathbf{0}\) bimaterial is identical to the linear elastic solution for one anisotropic media obtained by Sih et al. (1965) with corresponding elastic properties for each region, it provides a more rigorous framework and allows to justify the solution type (oscillatory versus non-oscillatory) by computing the matrix \(\mathbf{W}\).

Rights and permissions

About this article

Cite this article

Dontsova, E., Ballarini, R. Atomistic modeling of the fracture toughness of silicon and silicon-silicon interfaces. Int J Fract 207, 99–122 (2017). https://doi.org/10.1007/s10704-017-0224-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0224-0