Abstract

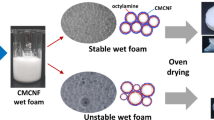

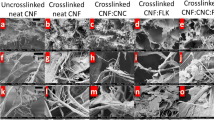

Ultra-lightweight cellulose foams were prepared by regeneration of sodium dodecyl sulfate (SDS)/cellulose/NaOH/urea blend solution via mechanical agitation and then freeze-drying. The morphology and properties of the blend solutions and foams were investigated via optical microscope, rheometer, BET and SEM. As a result, it was found that the inclusion complex structure between cellulose macromolecules and the solvent molecules was not destroyed. Moreover, the bubbles were about 20–50 μm in the solutions and larger (>100 μm) in the foams. Not only the micropores (bubbles) but also the nanopores could be observed in the wet and dried foams. The cellulose foams possessed ultra-low density of about 30 mg/cm3 and high specific surface area. The result of X-ray diffraction and Fourier transform infrared spectroscopy indicated that the cellulose foams were transited from cellulose I to cellulose II after dissolution and gelation. Bubbles inside the wet foams weakened the mechanical properties, but inversely increased the mechanical properties in the dried foams. Typical “J”-shaped curves were observed during the mechanical test, which revealed good compressive strength of dried foams. In this work, cellulose foams with ultra-lightweight and good mechanical properties were obtained, which exhibited great potentials for further development and comprehensive utilization of cellulose.

Similar content being viewed by others

References

Ahmadzadeh S, Nasirpour A, Keramat J, Hamdami N, Behzad T, Desobry S (2015) Nanoporous cellulose nanocomposite foams as high insulated food packaging materials. Colloids Surf, A 468:201–210

An W, Jiang L, Sun J, Liew KM (2015) Correlation analysis of sample thickness, heat flux, and cone calorimetry test data of polystyrene foam. J Therm Anal Calorim 119:229–238

Bernardini J, Cinelli P, Anguillesi I, Coltelli MB, Lazzeri A (2015) Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur Polymer J 64:147–156

Blomqvist R, Kostamo R, Rokman K (2008) Method and apparatus for foam forming, US Patent 7416636

Brown W, Wikström R (1965) A viscosity-molecular weight relationship for cellulose in cadoxen and a hydrodynamic interpretation. Eur Polymer J 1:1–10

Cai J, Zhang L (2006) Unique gelation behavior of cellulose in NaOH/Urea aqueous solution. Biomacromolecules 7:183–189

Cai J, Zhang L, Zhou J, Qi H, Chen H, Kondo T, Chen X, Chu B (2007) Multifilament fibers based on dissolution of cellulose in NaOH/urea aqueous solution: structure and properties. Adv Mater 19:821–825

Cai J, Zhang L, Liu S, Liu Y, Xu X, Chen X, Chu B, Guo X, Xu J, Cheng H (2008) Dynamic self-assembly induced rapid dissolution of cellulose at low temperatures. Macromolecules 41:9345–9351

Cai J, Liu S, Feng J, Kimura S, Wada M, Kuga P et al (2012) Cellulose–silica nanocomposite aerogels by in situ formation of silica in cellulose gel. Angew Chem Int Ed 124(9):2118–2121

Carlsson DO, Nystrom G, Zhou Q, Berglund LA, Nyholm L, Stromme M (2012) Electroactive nanofibrillated cellulose aerogel composites with tunable structural and electrochemical properties. J Mater Chem 22:19014–19024

Dorcheh AS, Abbasi MH (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Technol 199:10–26

Dwiggins JH, Bhat DM (2002) Foam forming method and apparatus, US Patent 6413368

Fengel D, Wegener G (1989) Wood: chemistry, ultrastructure, reactions. Walter de Gruyter, New York, pp 66–105

Fujii T, Yano T, Nakamur K, Miyawaki O (2001) The sol–gel preparation and characterization of nanoporous silica membrane with controlled pore size. J Memb Sci 187:171–180

Hua J, Marjo K, Ari L, Hanna PN, Jouni P, Abraham M, Olli I, Ras RHA (2011) Superhydrophobic and superoleophobic nanocellulose aerogel membranes as bioinspired cargo carriers on water and oil. Langmuir 27:1930–1934

Karlsson K, Schuster E, Stading M, Rigdahl M (2015) Foaming behavior of water-soluble cellulose derivatives: hydroxypropyl methylcellulose and ethyl hydroxyethyl cellulose. Cellulose 22:2651–2664

Kim Y, Cha M, Choi Y, Joo H, Lee J (2013) Electrokinetic separation of biomolecules through multiple nano-pores on membrane. Chem Phys Lett 561–562:63–67

Li R, Chang C, Zhou J, Zhang L, Gu W, Li C, Liu S, Kuga S (2010) Primarily industrialized trial of novel fibers spun from cellulose dope in NaOH/urea aqueous solution. Ind Eng Chem Res 49:11380–11384

Li R, Wang S, Lu A, Zhang L (2015) Dissolution of cellulose from different sources in an NaOH/urea aqueous system at low temperature. Cellulose 22:339–349

Lue A, Zhang L (2008) Investigation of the scaling law on cellulose solution prepared at low temperature. J Phys Chem B 112:4488–4495

Madani A, Zeinoddini S, Varahmi S, Turnbull H, Phillion AB, Olson JA, Martinez DM (2014) Ultra-lightweight paper foams: processing and properties. Cellulose 21:2023–2031

Pounder JR, Ahrens FW, Kershaw TN (1993) Multi-layer papers and tissues, US Patent 5227023

Qi H, Chang C, Zhang L (2009) Properties and applications of biodegradable transparent and photoluminescent cellulose films prepared via a green process. Green Chem 11:177–184

Quadrini F, Bellisario D, Santo L (2013) Recycling of thermoset polyurethane foams. Polym Eng Sci 53:1357–1363

Radvan B (1964) Basic Radfoam process, British Patent 1329409

Rokman K, Jansson J, Laine E (2001) Foam process for producing multi-layered webs, US Patent 6238518 B1

Shi X, Lu A, Jie C, Zhang L, Zhang H, Ji L, Wang X (2012) Rheological behaviors and miscibility of mixture solution of polyaniline and cellulose dissolved in an aqueous system. Biomacromolecules 13:2370–2378

Shi Z, Yang Q, Kuga S, Matsumoto Y (2015) Dissolution of wood pulps in aqueous NaOH/urea solution via dilute acid pretreatment. J Agric Food Chem 63(27):6113–6119

Skaugen B (1981) Foam generator for papermaking machine, US Patent 4299655

Vukovic I, Punzhin S, Vukovic Z, Onck P, De Hosson JTM, ten Brinke G, Loos K (2011) Supramolecular route to well-ordered metal nanofoams. ACS Nano 5:6339–6348

Zhang, L., Cai, J., Zhou, J. (2005). Manufacture of regenerated cellulose films and fibers. Chinese Patent ZL200310111566.3

Acknowledgment

This work was supported by Natural Science Foundation of Fujian Province (2016H6005) and Research Foundation of Education Bureau of Fujian Province (JB13037, JAT160148).

Author information

Authors and Affiliations

Corresponding author

Additional information

Joint first author: Jinyan Du.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, R., Du, J., Zheng, Y. et al. Ultra-lightweight cellulose foam material: preparation and properties. Cellulose 24, 1417–1426 (2017). https://doi.org/10.1007/s10570-017-1196-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1196-y