Abstract

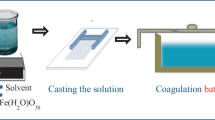

This work studies structure and properties of cellulose ultrafiltration membrane created by coupling of TiO2 nanoparticles onto the cellulose matrix. Supported cellulose ultrafiltration membranes were cast out of cellulose-titanium dioxide-ionic liquid solution via phase inversion. The aim was to determine the effect of titanium dioxide concentration on cellulose membrane morphology and performance. 1-ethyl-3-methylimidazolium acetate ([emim][OAc]) was used to obtain cellulose-ionic liquid solutions at a concentration of 9 %. Thin polymeric films of 250 µm thickness were cast onto a non-woven PET support material with an adjustable casting knife. Pure deionized water was employed as a non-solvent agent. The obtained product morphology (cross-section) was examined with field emission scanning electron microscopy. Filtration tests were made to determine pure water flux and molar mass cut-off (MMCO). Filtration tests with humic acid solutions were carried out to provide initial indications of performance in industrial applications. The obtained results showed that addition of titanium dioxide particles in small amounts had a positive impact on virgin cellulose ultrafiltration membranes. Tested samples had good mechanical stability, stable pure water flux and a MMCO typical for commercial ultrafiltration membranes. In addition, all tested samples showed excellent fouling resistance to humic acid solutions. In general, incorporation of titanium dioxide particles into cellulose matrix membrane should be taken into account as a potential way to create ultrafiltration membranes with high operation performance.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.References

Arsuaga JM, Sotto A, del Rosario G, Martinez A, Molina S, Teli SB, de Abajo J (2013) Influence of the type, size, and distribution of metal oxide particles on the properties of nanocomposite ultrafiltration membranes. J Membr Sci 428:131–141

Baker RW (2004) Membrane technology and applications. Wiley, Chichester

Balta S, Sotto A, Luis P, Benea L, Van der Bruggen B, Kim J (2012) A new outlook on membrane enhancement with nanoparticles: the alternative of ZnO. J Memb Sci 389:155–161

Cao Y, Wu J, Zhang J, Li H, Zhang Y, He J (2009) Room temperature ionic liquids (RTILs): a new and versatile platform for cellulose processing and derivatization. Chem Eng J 147:13–21

Cao Y, Li H, Zhang Y, Zhang J, He J (2010) Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J Appl Polym Sci 116:547–554

Costa AR, de Pinho MN (2005) Effect of membrane pore size and solution chemistry on the ultrafiltration of humic substances solutions. J Membr Sci 255:49–56

Fink HP, Ganster J, Lehmann A (2014) Progress in cellulose shaping: 20 years industrial case studies at Fraunhofer IAP. Cellulose 21:31–51

Gericke M, Fardim P, Heinze T (2012) Ionic liquids—promising but challenging solvents for homogeneous derivatization of cellulose. Molecules 17:7458–7502

Gullinkala T, Escobar I (2010) A green membrane functionalization method to decrease natural organic matter fouling. J Membr Sci 360:155–164

Hameed N, Xiong R, Salim NV, Guo Q (2013) Fabrication and characterization of transparent and biodegradable cellulose/poly(vinyl alcohol) blend films using an ionic liquid. Cellulose 20:2517–2527

Huang J, Zhang K, Wang K, Xie Z, Ladewig B, Wang H (2012) Fabrication of polyethersulfone-mesoporous silica nanocomposite ultrafiltration membranes with antifouling properties. J Membr Sci 423–424:362–370

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15:59–66

Li JH, Xu YY, Zhu LP, Wang JH, Du GH (2009) Fabrication and characterization of a novel TiO2 nanoparticle self-assembly membrane with improved fouling resistance. J Membr Sci 326:659–666

Li XL, Zhu LP, Zhu BK, Xu YY (2011) High-flux and anti-fouling cellulose nanofiltration membranes prepared via phase inversion with ionic liquid as solvent. Sep Purif Technol 83:66–73

Liu X, Pang J, Zhang X, Wu Y, Sun R (2013) Regenerated cellulose film with enhanced tensile strength prepared with ionic liquid 1-ethyl-3-methylimidazolium acetate (EMIMAc). Cellulose 20:1391–1399

Mulder M (2003) Basic principles of membrane technology. Kluwer, Dordrecht

Oh SJ, Kim N, Lee YT (2009) Preparation and characterization of PVDF/TiO2 organic-inorganic composite membranes for fouling resistance improvement. J Membr Sci 345:13–20

Pinkert A, Marsh KN, Pang S, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728

Reuvers AJ, van den Berg JWA, Smolders CA (1987) Formation of membranes by means of immersion precipitation: part I. A model to describe mass transfer during immersion precipitation. J Membr Sci 34:45–65

Sotto A, Boromand A, Balta S, Kim J, Van der Bruggen B (2011) Doping of polyethersulfone nanofiltration membranes: antifouling effect observed at ultralow concentrations of TiO2 nanoparticles. J Mater Chem 21:10311–10320

Stade S, Kallioinen M, Mikkola A, Tuuva T, Mänttäri M (2013) Reversible and irreversible compaction of ultrafiltration membranes. Sep Purif Technol 118:127–134

Yang Y, Wang P, Zheng Q (2006) Preparation and properties of polysulfone/TiO2 composite ultrafiltration membranes. J Polym Sci 44:879–887

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhu T, Lin Y, Luo Y, Hu X, Lin W, Yu P, Huang C (2012) Preparation and characterization of TiO2-regenerated cellulose inorganic-polymer hybrid membranes for dehydration of caprolactam. Carbohydr Polym 87(2012):901–909

Acknowledgments

The authors would like to thank Ahlstrom Filtration LLC (USA) for donation of the membrane support material, Dr. Judy Lee (Melbourne University) for the FESEM micrographs of the prepared membranes, and the Finnish Bioeconomy Cluster (FIBIC) and TEKES—the Finnish Funding Agency for Innovation (FuBio JR2 project) for financial support. Peter G. Jones is thanked for language checking.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nevstrueva, D., Pihlajamäki, A. & Mänttäri, M. Effect of a TiO2 additive on the morphology and permeability of cellulose ultrafiltration membranes prepared via immersion precipitation with ionic liquid as a solvent. Cellulose 22, 3865–3876 (2015). https://doi.org/10.1007/s10570-015-0746-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0746-4