Abstract

Natural lignin would not be readily utilized due to its heterogeneity and structural complexity, moreover, the reactivity of the lignin that experienced the acid biorefinery process becomes lower. It has become a major issue to break the anti-degradation barriers of the highly inert acid-refining residue. A new strategy based on the design of attapulgite-supported niobium catalyst (ANC) was proposed to liquefy the acid-refining residue in water–ethanol co-solvent. Concentrated acid hydrolysis lignins (CAHLs), dilute acid hydrolysis lignins (DAHLs) and acid-enzymatic hydrolysis lignins (AEHLs) from different feedstocks, were prepared purposefully to evaluate the catalytic activity of ANC. All the highly inert residues could be efficaciously liquefied by ANC. The addition of niobium species significantly improved the yield of guaiacol and promoted the production of 4-methylcatechol. Reusability test suggested that ANC could be used at least five times. The results provide the possibility for the industrial application of this strategy.

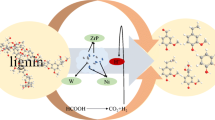

Graphical abstract

Catalytic liquefaction of highly inert refining residue over an attapulgite-supported niobium catalyst in ethanol

Similar content being viewed by others

References

Liu Y, Nie Y, Lu X, Zhang X, He H, Pan F, Zhou L, Liu X, Ji X, Zhang S (2019) Cascade utilization of lignocellulosic biomass to high-value products. Green Chem 21(13):3499–3535

Lange JP (2018) Lignocellulose liquefaction to biocrude: a tutorial review. Chemsuschem 11(6):997–1014

Bungay HR (1982) Biomass refining. Science 218:643–646

Luo L, van der Voet E, Huppes G (2010) Biorefining of lignocellulosic feedstock-technical, economic and environmental considerations. Bioresour Technol 101(13):5023–5032

Sun Z, Fridrich B, de Santi A, Elangovan S, Barta K (2018) Bright side of lignin depolymerization: toward new platform chemicals. Chem Rev 118(2):614–678

Iranmahboob J, Nadim F, Monemi S (2002) Optimizing acid-hydrolysis: a critical step for production of ethanol from mixed wood chips. Biomass Bioenergy 22:401–404

Rabinovich ML, Fedoryak O, Dobele G, Andersone A, Gawdzik B, Lindström ME, Sevastyanova O (2016) Carbon adsorbents from industrial hydrolysis lignin: the USSR/Eastern European experience and its importance for modern biorefineries. Renew Sust Energ Rev 57:1008–1024

Li C, Zhao X, Wang A, Huber GW, Zhang T (2015) Catalytic transformation of lignin for the production of chemicals and fuels. Chem Rev 115(21):11559–11624

Deuss PJ, Scott M, Tran F, Westwood NJ, de Vries JG, Barta K (2015) Aromatic monomers by in situ conversion of reactive intermediates in the acid-catalyzed depolymerization of lignin. J Am Chem Soc 137(23):7456–7467

Dutta T, Isern NG, Sun J, Wang E, Hull S, Cort JR, Simmons BA, Singh S (2017) Survey of lignin-structure changes and depolymerization during ionic liquid pretreatment. ACS Sustain Chem Eng 5(11):10116–10127

Matsushita Y, Yasuda S (2005) Preparation and evaluation of lignosulfonates as a dispersant for gypsum paste from acid hydrolysis lignin. Bioresour Technol 96(4):465–470

Matsushita Y, Yasuda S (2003) Preparation of anion-exchange resins from pine sulfuric acid lignin, one of the acid hydrolysis lignins. J Wood Sci 49(5):423–429

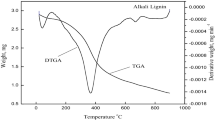

Huang Y, Wei Z, Qiu Z, Yin X, Wu C (2012) Study on structure and pyrolysis behavior of lignin derived from corncob acid hydrolysis residue. J Anal Appl Pyrolysis 93:153–159

Zhang B, Yin X, Wu C, Qiu Z, Wang C, Huang Y, Ma L, Wu S (2012) Structure and pyrolysis characteristics of lignin derived from wood powder hydrolysis residues. Appl Biochem Biotechnol 168(1):37–46

Zhang H, Ding F, Luo C, Xiong L, Chen X (2012) Liquefaction and characterization of acid hydrolysis residue of corncob in polyhydric alcohols. Ind Crops Prod 39:47–51

Kristianto I, Limarta SO, Lee H, Ha JM, Suh DJ, Jae J (2017) Effective depolymerization of concentrated acid hydrolysis lignin using a carbon-supported ruthenium catalyst in ethanol/formic acid media. Bioresour Technol 234:424–431

Wu Z, Hu L, Jiang Y, Wang X, Xu J, Wang Q, Jiang S (2020) Recent advances in the acid-catalyzed conversion of lignin. Biomass Convers Biorpur. https://doi.org/10.1007/s13399-020-00976-8

Wang GS, Lee JW, Zhu JY, Jeffries TW (2011) Dilute acid pretreatment of corncob for efficient sugar production. Appl Biochem Biotechnol 163(5):658–668

Satari Baboukani B, Vossoughi M, Alemzadeh I (2012) Optimisation of dilute-acid pretreatment conditions for enhancement sugar recovery and enzymatic hydrolysis of wheat straw. Biosyst Eng 111(2):166–174

Wu Z, Zhang J, Zhao X, Li X, Zhang Y, Wang F (2019) Attapulgite-supported magnetic dual acid–base catalyst for the catalytic conversion of lignin to phenolic monomers. J Chem Technol Biotechnol 94(4):1269–1281

Pushpaletha P, Lalithambika M (2011) Modified attapulgite: an efficient solid acid catalyst for acetylation of alcohols using acetic acid. Appl Clay Sci 51(4):424–430

Kong L, Zhang L, Gu J, Gou L, Xie L, Wang Y, Dai L (2020) Catalytic hydrotreatment of kraft lignin into aromatic alcohols over nickel-rhenium supported on niobium oxide catalyst. Bioresour Technol 299:122582

Ansanay Y, Kolar P, Sharma-Shivappa RR, Cheng JJ (2014) Niobium oxide catalyst for delignification of switchgrass for fermentable sugar production. Ind Crops Prod 52:790–795

Ma D, Lu S, Liu X, Guo Y, Wang Y (2019) Depolymerization and hydrodeoxygenation of lignin to aromatic hydrocarbons with a Ru catalyst on a variety of Nb-based supports. Chin J Catal 40(4):609–617

Cao J-P, Xie T, Zhao XY, Zhu C, Wei J, Zhao M, Zhao Y-P, Wei X-Y (2021) Selective cleavage of ether C–O bond in lignin-derived compounds over Ru system under different H-sources. Fuel 284:119027

Guo H, Li Q, Zhang H, Xiong L, Peng F, Yao S, Chen X (2019) Attapulgite supported Cu–Fe–Co based catalyst combination system for CO hydrogenation to lower alcohols. J Fuel Chem Technol 47(11):1346–1356

Chen M, Wang Y, Yang Z, Liang T, Liu S, Zhou Z, Li X (2018) Effect of Mg-modified mesoporous Ni/attapulgite catalysts on catalytic performance and resistance to carbon deposition for ethanol steam reforming. Fuel 220:32–46

Su T, Peng R, Hood ZD, Naguib M, Ivanov IN, Keum JK, Qin Z, Guo Z, Wu Z (2018) One-step synthesis of Nb2O5/C/Nb2C (MXene) composites and their use as photocatalysts for hydrogen evolution. Chemsuschem 11(4):688–699

Yu Y-M, Cheng Z-M, Zhou Z-M, Wu S-C, Liu P, Jin J (2011) Regulation of catalytic reaction via vapor-phase condensation. 1. Experimental study on the reaction rate hysteresis loops. Ind Eng Chem Res 51(26):8735–8741

Hidajat MJ, Riaz A, Park J, Insyani R, Verma D, Kim J (2017) Depolymerization of concentrated sulfuric acid hydrolysis lignin to high-yield aromatic monomers in basic sub- and supercritical fluids. Chem Eng J 317:9–19

Ma R, Guo M, Lin KT, Hebert VR, Zhang J, Wolcott MP, Quintero M, Ramasamy KK, Chen X, Zhang X (2016) Peracetic acid depolymerization of biorefinery lignin for production of selective monomeric phenolic compounds. Chem Eur J 22(31):10884–10891

Cheng S, Wilks C, Yuan Z, Leitch M, Xu C (2012) Hydrothermal degradation of alkali lignin to bio-phenolic compounds in sub/supercritical ethanol and water-ethanol co-solvent. Polym Degrad Stab 97(6):839–848

Dong L, Lin L, Han X, Si X, Liu X, Guo Y, Lu F, Rudić S, Parker SF, Yang S, Wang Y (2019) Breaking the limit of lignin monomer production via cleavage of interunit carbon-carbon linkages. Chem 5(6):1521–1536

Jin S, Xiao Z, Chen X, Wang L, Guo J, Zhang M, Liang C (2015) Cleavage of lignin-derived 4-O-5 aryl ethers over nickel nanoparticles supported on niobic acid-activated carbon composites. Ind Eng Chem Res 54(8):2302–2310

Li M, Zhang W, Zhou S, Zhao Y (2020) Preparation of poly (vinyl alcohol)/palygorskite-poly (ionic liquids) hybrid catalytic membranes to facilitate esterification. Sep Purif Technol 230:115746

Guan W, Chen X, Jin S, Li C, Tsang C-W, Liang C (2017) Highly stable Nb2O5-Al2O3 composites supported Pt catalysts for hydrodeoxygenation of diphenyl ether. Ind Eng Chem Res 56(47):14034–14042

Kim JY, Heo S, Choi JW (2018) Effects of phenolic hydroxyl functionality on lignin pyrolysis over zeolite catalyst. Fuel 232:81–89

Hernando H, Ochoa-Hernández C, Shamzhy M, Moreno I, Fermoso J, Pizarro P, Coronado JM, Čejka J, Serrano DP (2019) The crucial role of clay binders in the performance of ZSM-5 based materials for biomass catalytic pyrolysis. Catal Sci Technol 9(3):789–802

Acknowledgements

The authors are grateful for financial support from the National Natural Science Foundation of China (Grant Nos. 22078123, 21908075), the Natural Science Foundation of Jiangsu Province (Grant Nos. BK20201072, BK20191056 and BK20190105), the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province (Grant No. 19KJB220006), and the Natural Science Foundation of Huai'an City (Grant No. HAB202057).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, Z., Jiang, Y., Wang, X. et al. Catalytic Liquefaction of Highly Inert Refining Residue over an Attapulgite-Supported Niobium Catalyst. Catal Lett 152, 3388–3399 (2022). https://doi.org/10.1007/s10562-021-03889-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-021-03889-x